Partitioned drilling, cutting and alkali injection treatment construction method for soft, low-permeability and high-hydrogen-sulfide coal seam

A construction method and hydrogen sulfide technology, applied in earthwork drilling, wellbore/well components, mining equipment, etc., can solve the problems of hydrogen sulfide gas extraction, difficult hydraulic jet flow, poor treatment effect, etc., and achieve high injection efficiency. Reduce the amount of alkali, save the cost of treatment, and achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

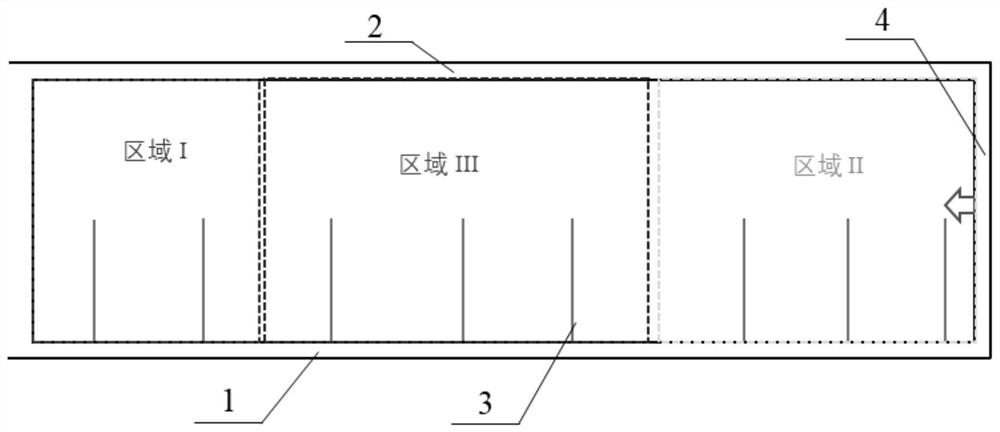

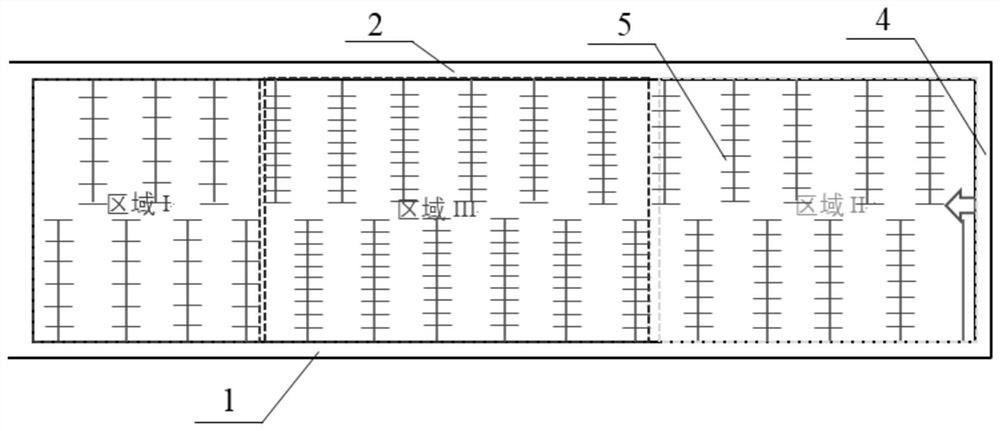

[0027] combine figure 1 — figure 2 As shown, a soft, low permeability, high hydrogen sulfide coal seam partition drilling and cutting alkali injection treatment construction method, including the following steps:

[0028] 1) Detection and area division: multiple hydrogen sulfide detection boreholes 3 are constructed in the coal seam to detect whether the concentration of hydrogen sulfide in each detection borehole 3 exceeds the standard, and the target coal seam exceeding the standard is divided into regions according to the detected hydrogen sulfide concentration to obtain In the high (area III), medium (area II) and low (area I) coal seam areas, the exploration borehole 3 is sealed. For coal seams where the concentration of hydrogen sulfide has not exceeded the standard, no subsequent alkali injection treatment will be performed.

[0029] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com