Construction method of drilling, cutting and alkali injection treatment in soft, low permeability and high hydrogen sulfide coal seams

A construction method, hydrogen sulfide technology, applied in earthwork drilling, wellbore/well components, mining equipment, etc., can solve the problems of hydrogen sulfide gas extraction, poor treatment effect, difficult hydraulic jet, etc., to improve injection The effect of reducing the amount of alkali, achieving reuse, and saving treatment costs

Active Publication Date: 2022-06-03

CHONGQING UNIV +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The latter two methods are relatively effective in high-permeability coal seams, but for soft and low-permeability coal seams, it is difficult to extract hydrogen sulfide gas in coal seams by using the third method. , it is difficult to inject lye into the coal seam, resulting in a small range of influence and poor control effect

5) The traditional hydraulic jet construction method is to construct the borehole first and then perform the hydraulic jet. Because the coal body around the pre-constructed drill hole is soft and the hole collapses, it is difficult to carry out the next hydraulic jet. This method is only suitable for relatively complete coal seams. , hard area

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0036] Preferably, in step 5), the lye using mass concentration is 1% sodium carbonate solution, and the alkali injection pressure is 4-5MPa.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

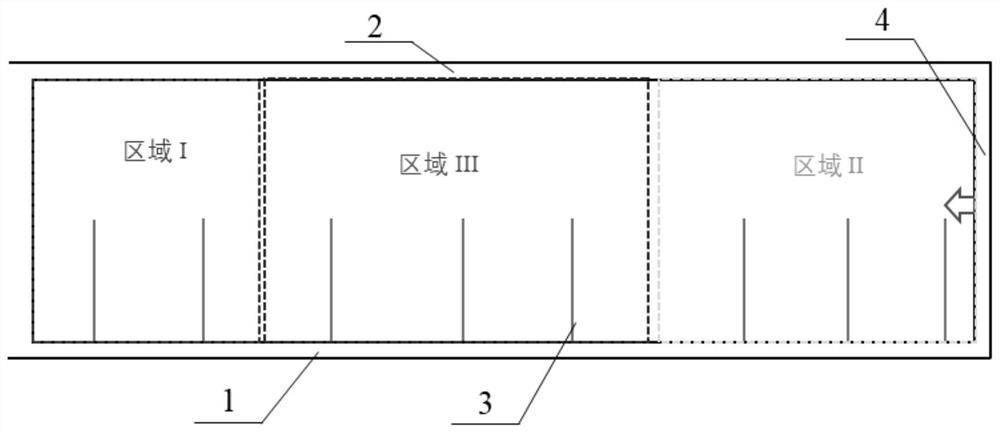

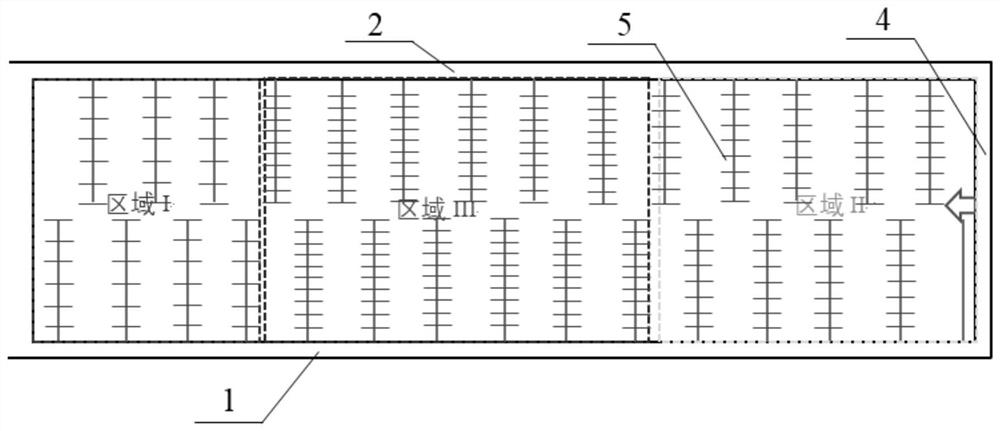

The invention discloses a soft, low permeability, high hydrogen sulfide coal seam partition drilling and cutting alkali injection treatment construction method, comprising 1) detection and area division; 2) alkali injection parameter design; 3) hydraulic slotting drilling; 4) hole sealing ; 5) caustic injection in drilling; 6) investigation of caustic injection effect and adjustment of hydraulic slotted drilling parameters; 7) real-time detection of hydrogen sulfide outflow during coal mining, and determination of hydrogen sulfide concentration by hydrogen sulfide concentration detector. The monitoring results modify the hydraulic slotting distance in step 3), and adjust the amount of alkali injection and the number of drill holes at the same time to ensure that the hydrogen sulfide concentration is lower than the safe value of 6.6ppm when the coal seam is recovered in other areas. The present invention adopts the integrated technology of hydraulic slotting and drilling to expand the amount of alkali injection and treatment range of the coal seam, and adopts different hydraulic slotting arrangements according to different hydrogen sulfide content areas, which can greatly improve the efficiency of coal seam hydrogen sulfide treatment, and at the same time ensure that the underground Workers and related equipment are protected from the hazards of hydrogen sulfide.

Description

Construction method for zone drilling, cutting and injection of alkali in soft, low permeability and high hydrogen sulfide coal seam technical field The invention belongs to the hydrogen sulfide coal seam mining technical field, be specifically related to a kind of soft, low permeability, high hydrogen sulfide coal seam separation District drilling cutting and alkali injection treatment construction method. Background technique [0002] With the continuous exploitation of coal resources in my country, the cases of hydrogen sulfide gushing in the coal seam gradually increase, and the coal seam The abnormal outflow of hydrogen sulfide seriously threatens the safe production of mines. Its hazards are mainly manifested in: 1) hydrogen sulfide gas molecules in The amount of adsorption in coal is huge, about 90 times that of methane, so it is more prone to hydrogen sulfide gushing out of boreholes; 2) Hydrogen sulfide is a A toxic gas, when its concentration reaches 100ppm,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21F7/00E21B43/00E21B43/22E21B43/26E21B33/13

CPCE21F7/00E21B43/006E21B43/16E21B43/261E21B33/13

Inventor 王浩张东明王小蕾饶孜胡雷谯石余北辰肖伟晶

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com