End ore-drawing caving mining technology with high efficient using steel concrete composite man-made false roofs

A technology of artificial false roof and steel-concrete structure, applied in ground mining, mining equipment, earthwork drilling and other directions, can solve the problems of complex construction, low work efficiency, complicated roof laying process, etc., to improve the ore recovery rate and solve the problem of poor loss the effect of reducing the dilution of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An application example of mining technology using artificial false roof with steel-concrete structure in end-drawing sub-level caving method without bottom pillar.

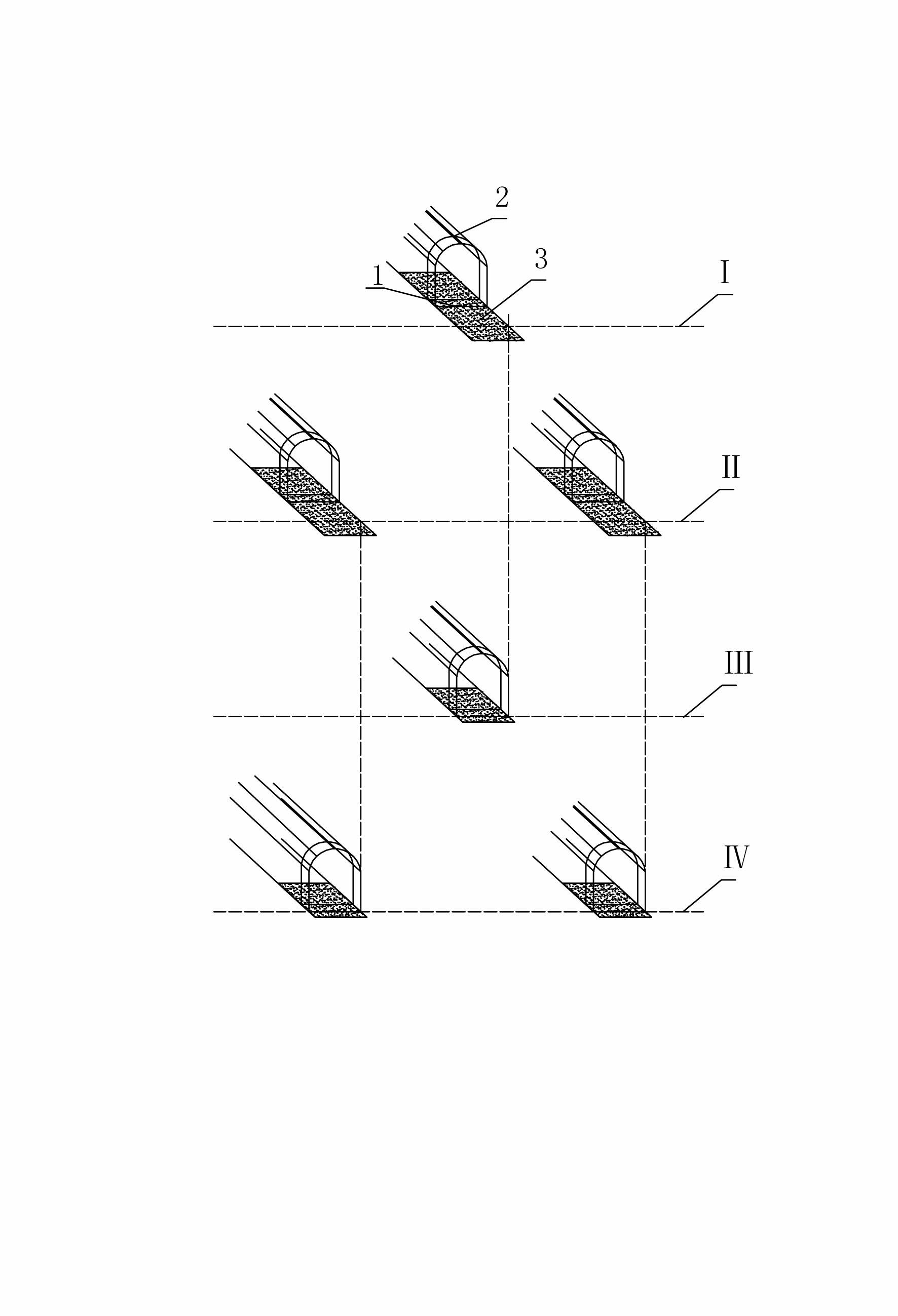

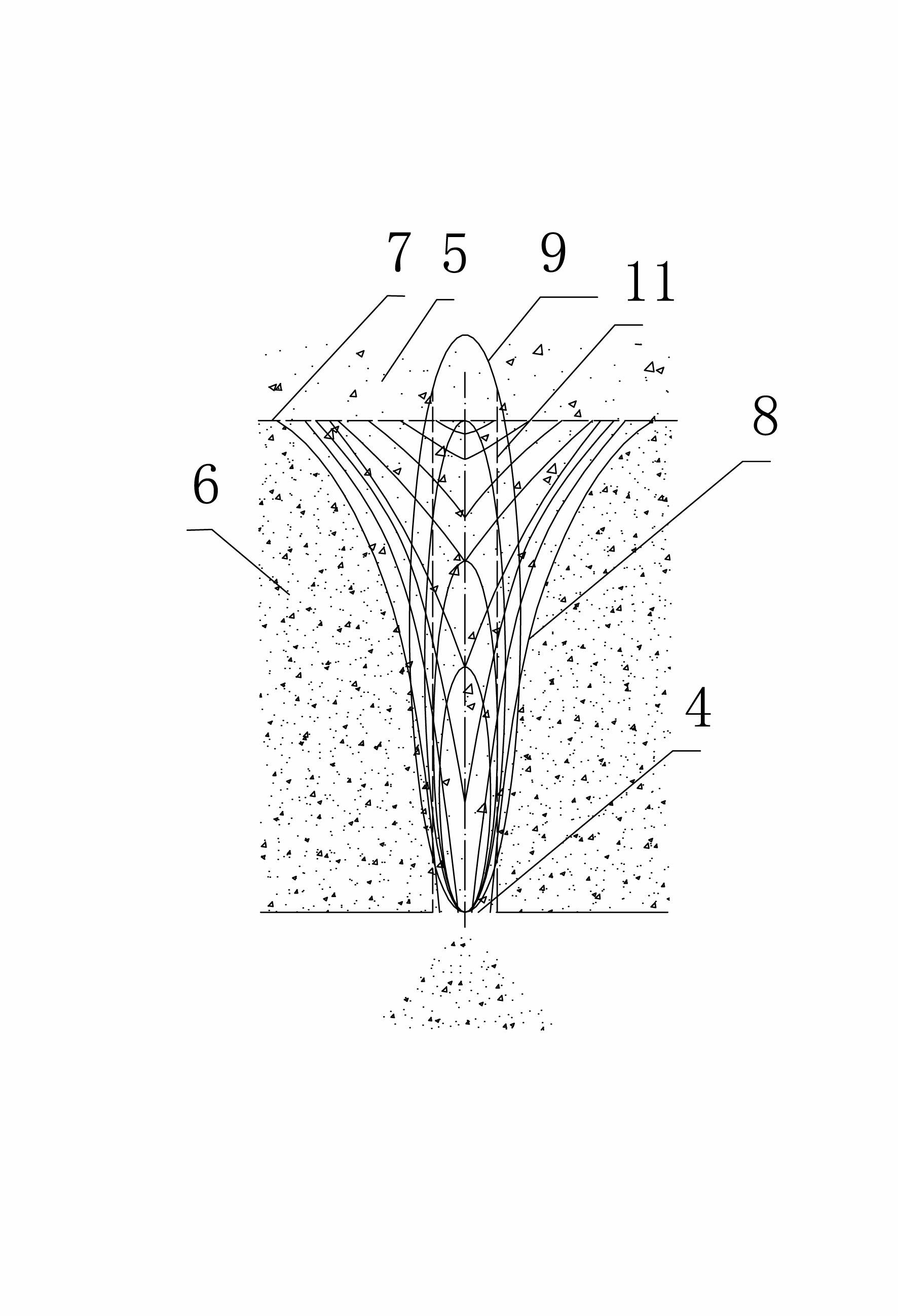

[0040] figure 1 It is an example of mining technology using steel-concrete structure artificial false roof in end-drawing ore-drawing step-by-step caving method, without changing the mining method of step-by-step caving method without bottom pillar, the mining roadways are arranged in a rhombus-shaped staggered manner , complete rock drilling, blasting and ore extraction in the mining roadway, and the mining roadway is the mining route 2, which is also the ore opening. This application example is characterized in that: the control point of the waste rock funnel is the bottom of the entire mining roadway, therefore, it only needs to be continuously laid at the bottom of all mining roadways 2 ends with mining roadways directly below with the mining of the mining face 1 Steel-concrete structure artificial fal...

Embodiment 2

[0042] Application example of mining technology using artificial false roof with steel-concrete structure in end-drawing sub-level caving method

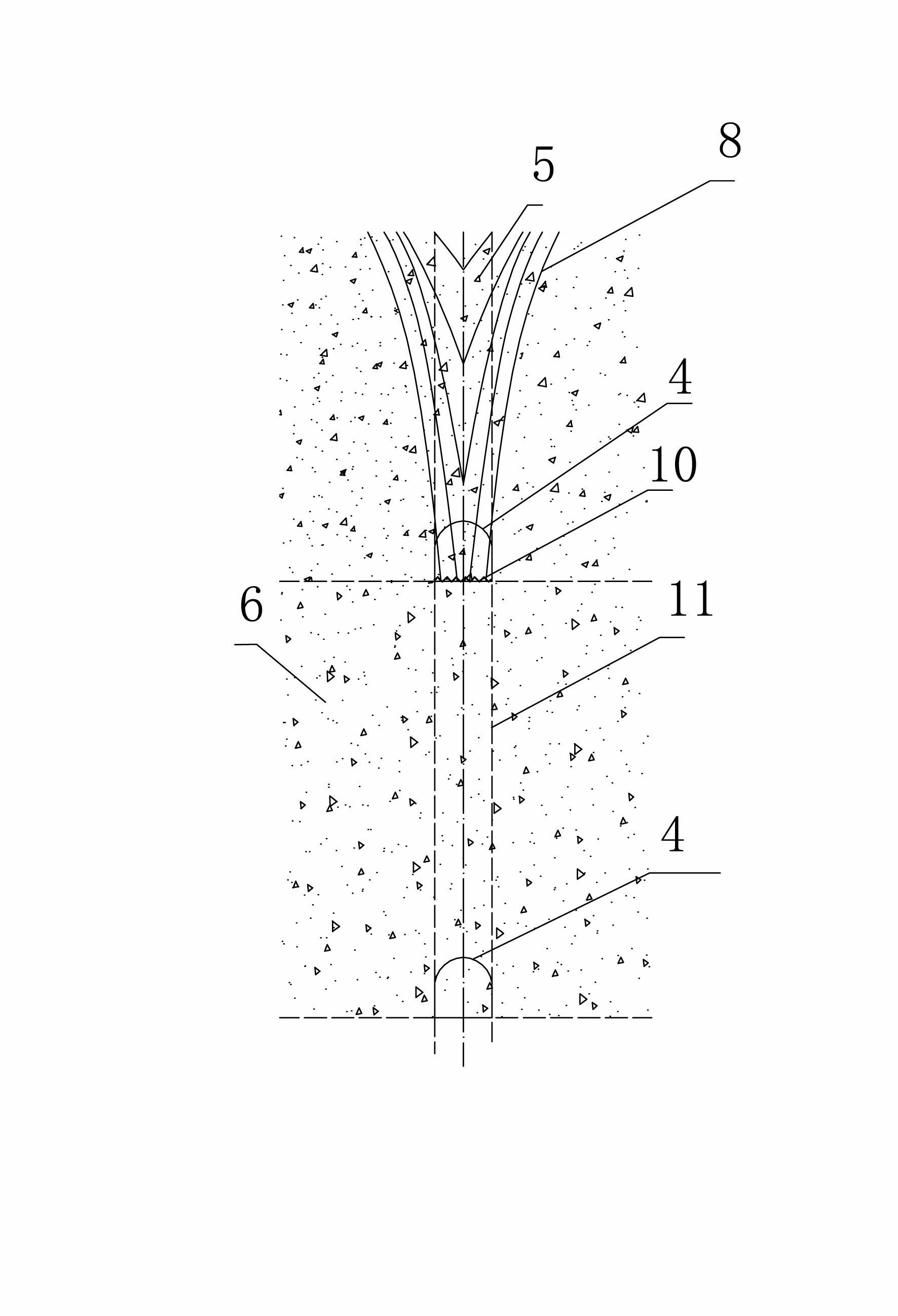

[0043] Image 6 It is a schematic diagram of an example of the mining process using a steel-concrete structure artificial false roof in the segmented caving method with bottom pillars at the end of ore drawing according to the present invention.

[0044] The mining approach with sub-column caving method is composed of a rock-drilling roadway for ore falling and a bottom structure equipped with ore drawing, ore receiving and ore transportation. There are three types of structures: funnel type, trench type and flat bottom type. The bottom structure is arranged with ore-receiving roadway 15 and electric rake roadway 13. Under the condition of not changing the mining method of sub-section caving method with pillars, the mining approach is diamond-shaped Arranged in a staggered manner, the ore is drawn through the ore-receiving roadway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com