Bottom-post-free sublevel caving method adopting reinforced concrete structure artificial false roof

A technology of segmented caving method and artificial false roof, which is applied in ground mining, blasting, earthwork drilling and other directions, can solve the problems of complex construction, high material consumption, lack of research on waste rock hopper control, etc. The effect of ore dilution and improving ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

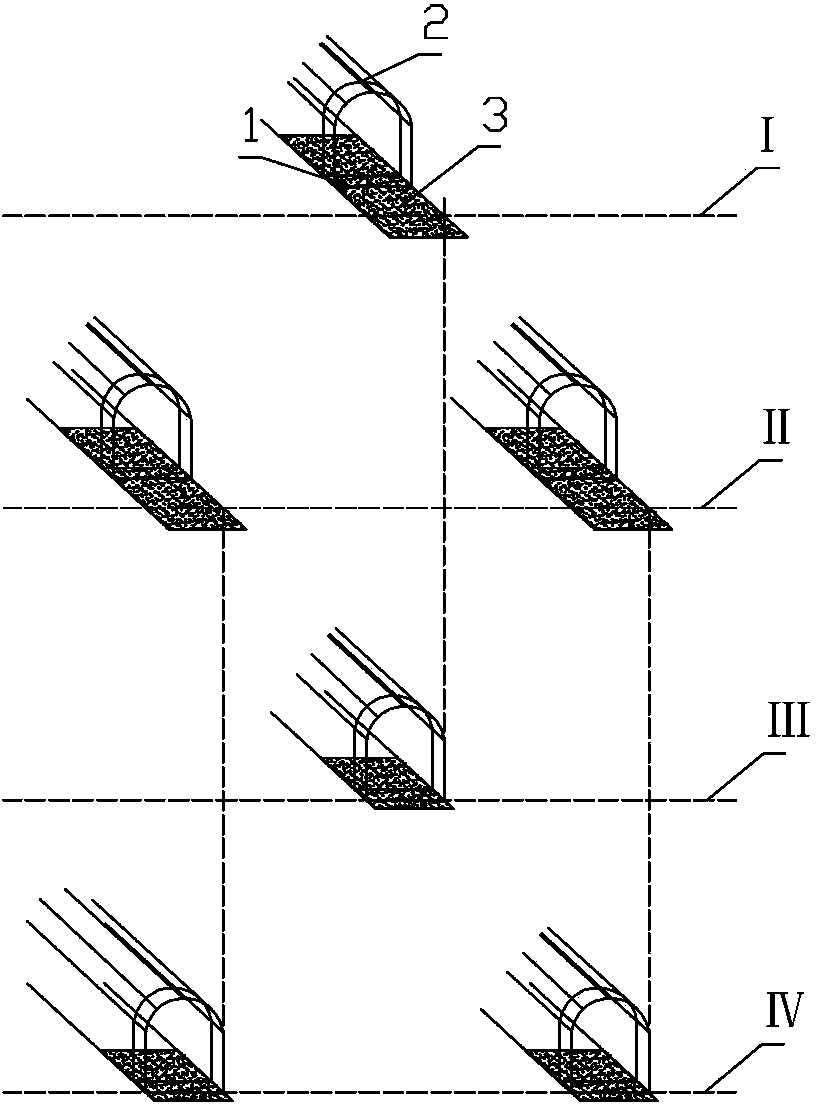

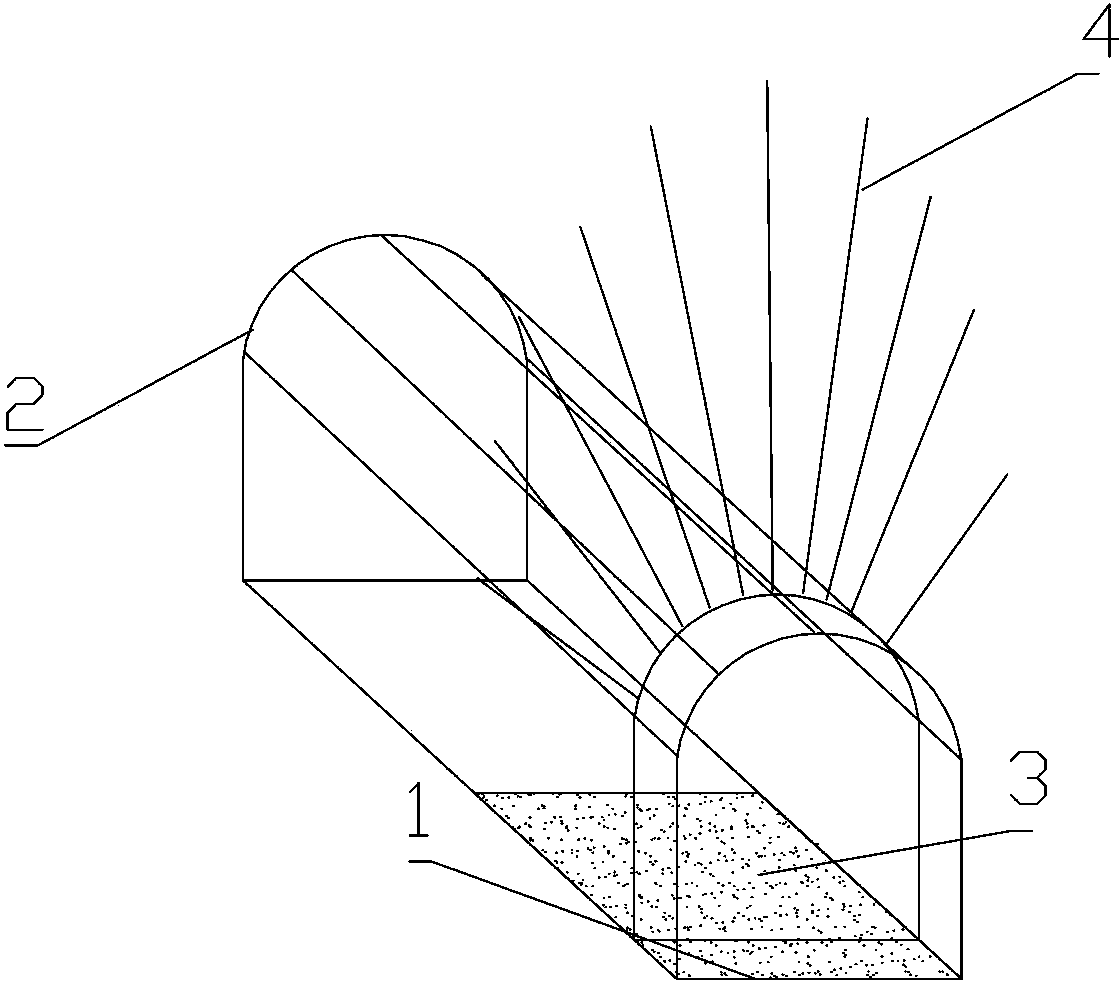

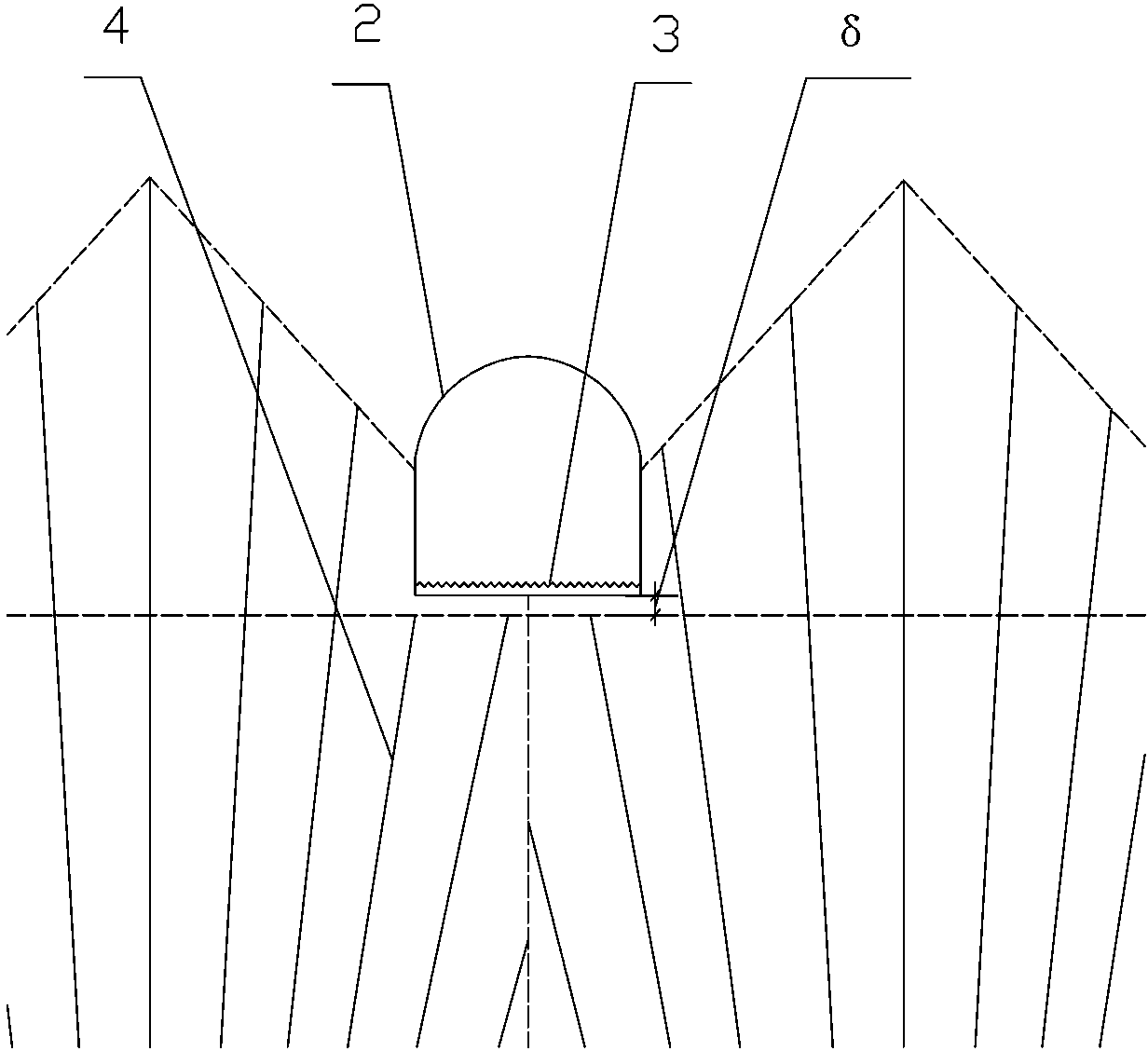

[0034] Such as figure 1 , figure 2 , image 3 , Figure 5As shown, the artificial false roof with steel-concrete structure of the present invention has no bottom column stage caving method, including carrying out subsection mining under the overburden rock formation 5, and the upper and lower subsection mining roadways 2 are arranged in a rhombus staggered manner, and rock drilling, Blasting and mining, characterized in that with the recovery of the mining face 1, there are waste rock funnel control points 12 at the end of the mining roadway 2 of all the mining routes directly below, and the steel pipes with the same width as the mining roadway 2 are continuously laid. Mixed structure artificial roof 3, all the mining tunnels 2 with artificial roof 3 directly above carry out rock drilling, blasting and mining under the cover of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com