Gently inclined minded-out area roof and floor residual ore stoping method

A roof-floor, gently-inclined technology, which is applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of poor safety, difficulty in mining, and low efficiency of mining operations, reduce mining and filling costs, and eliminate hidden dangers in empty areas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

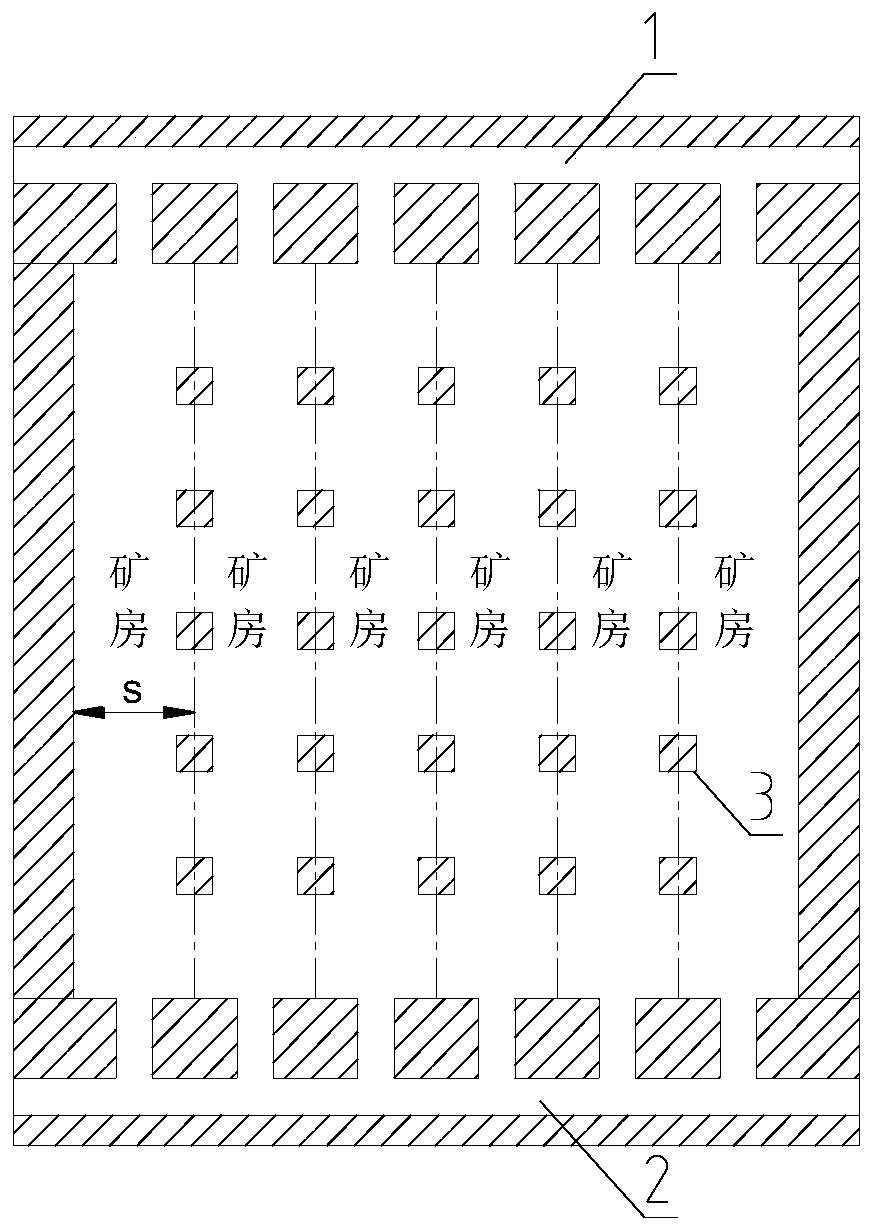

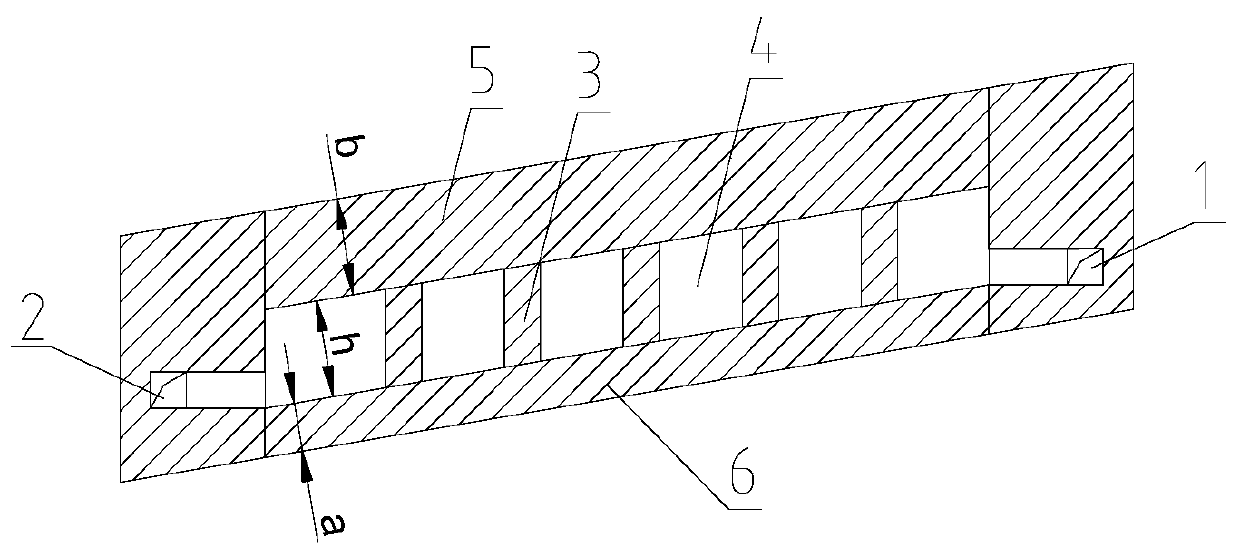

[0031] From Figure 1-Figure 5 It can be seen that a kind of gently inclined goaf roof and floor residual ore mining method provided by the present invention comprises the following steps:

[0032] (step 1), adopt the three-dimensional laser scanner to scan the old goaf 4 form of the original house-and-pillar method, measure the span of the mine house s=10m, and calculate the old goaf by the area and volume of the old goaf 4 4 Average thickness h=10m;

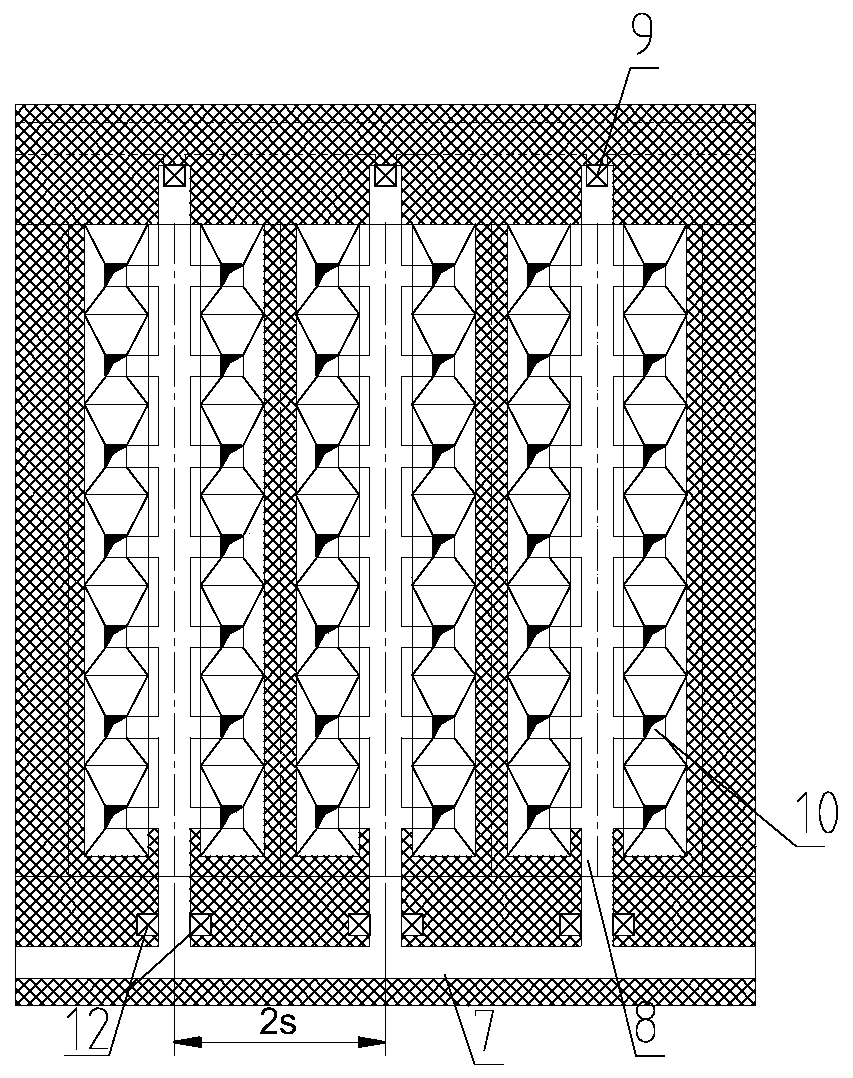

[0033] (Step 2), from the footwall ramp construction connection road to the orebody floor surrounding rock, then construct a footwall along vein transportation lane 7 along the ore body, the footwall along vein transportation lane 7 section specification is 3m * 3m, From the footwall along the vein transportation roadway 7, construct an inclined uphill 8 at intervals of 20m along the inclination direction to the top column in the upper middle section. The inclined uphill 8 is located on the center line of the two mine houses i...

Embodiment 2

[0040] From Figure 1-Figure 5 It can be seen that a kind of gently inclined goaf roof and floor residual ore mining method provided by the present invention comprises the following steps:

[0041] (step 1), adopt the three-dimensional laser scanner to scan the old goaf 4 form of the original house-pillar method, measure the span of the mine house s=8m, and calculate the old goaf by the area and volume of the old goaf 4 4 Average thickness h=9m;

[0042] (Step 2), from the footwall ramp construction connection road to the orebody floor surrounding rock, then construct a footwall along vein transportation lane 7 along the ore body, the footwall along vein transportation lane 7 section specification is 3m * 3m, From the footwall along the vein transportation roadway 7, a sloped uphill 8 is constructed at intervals of 16m along the inclination direction to the top column of the upper middle section. The sloped uphill 8 is located on the center line of the two mine houses in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com