Progressive caving mining method

A technology of caving mining and caving ore, which is applied in the field of continuous caving mining in metal mines, can solve the problems of wasting mineral resources, large mining loss rate and mining dilution rate, and reducing the benefits of mining enterprises, achieving long ore body strike length, The effect of low mining loss rate and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

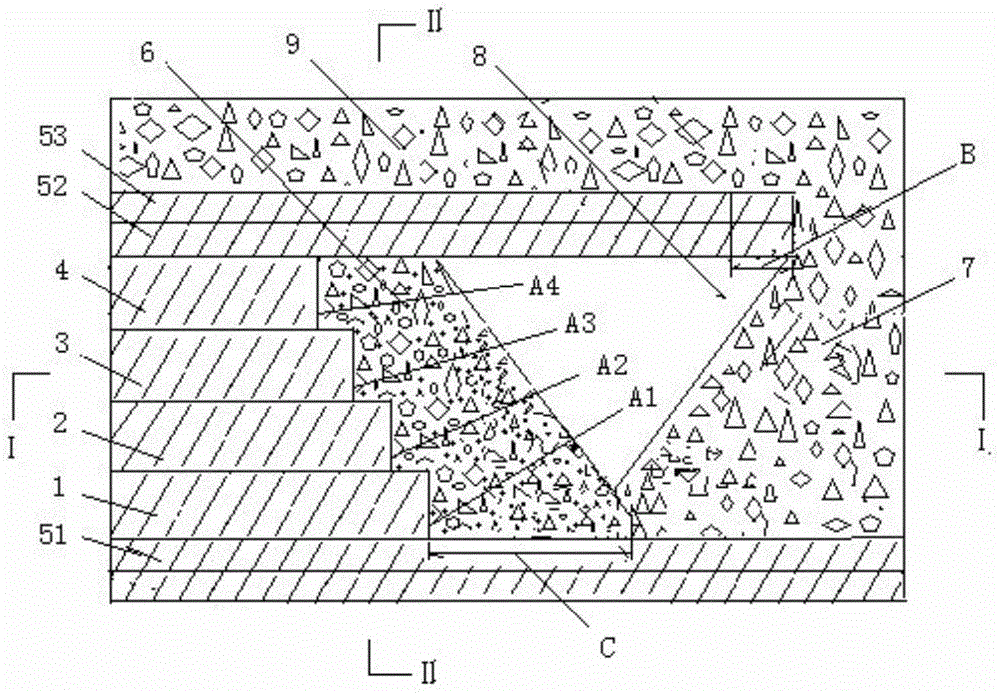

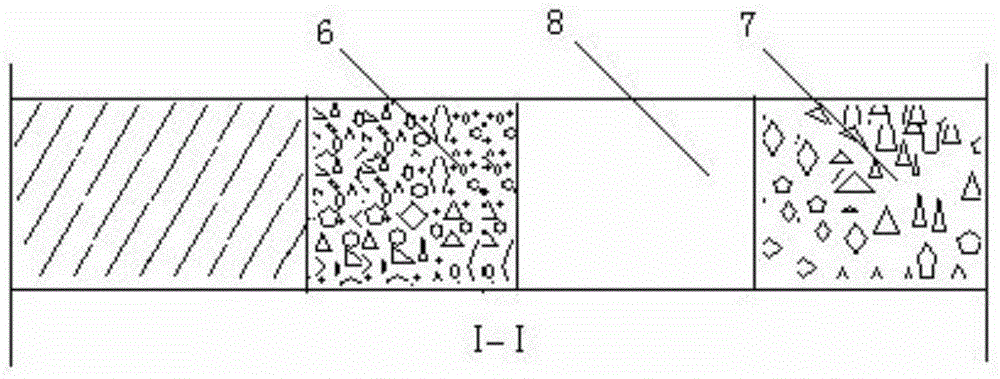

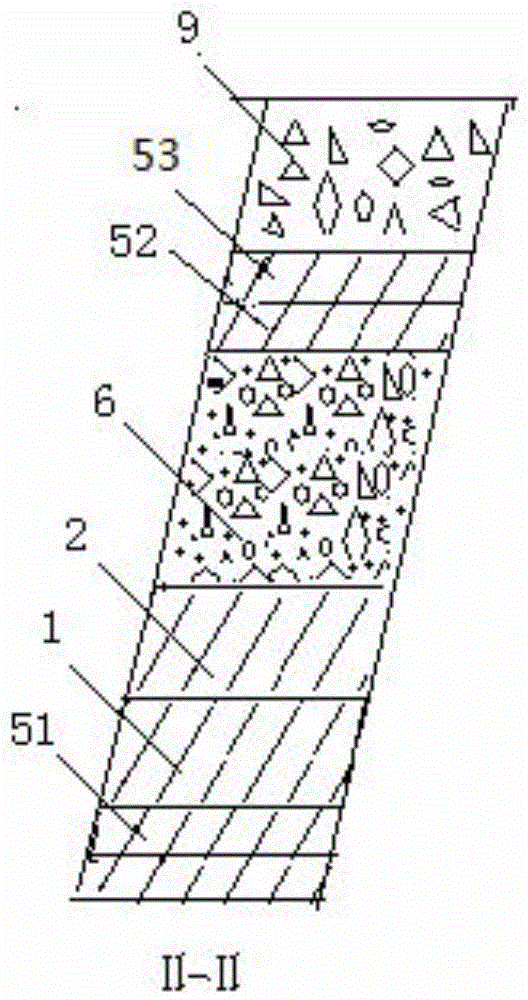

[0022] figure 1 It is a schematic longitudinal section diagram of the continuous caving mining method scheme of the preferred embodiment of the present invention; figure 2 It is a schematic horizontal section diagram of the continuous caving mining method scheme of the preferred embodiment of the present invention; image 3 It is a schematic cross-sectional view of the continuous caving mining method scheme of the preferred embodiment of the present invention.

[0023] Such as figure 1 As shown, in the continuous caving mining method of this embodiment, the ore body is divided into the ore section with the full length of the strike along the vertical direction of the ore body at a certain height as the middle section, and the middle section of the ore section is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com