Mechanized filling mining method for steeply inclined thin vein under soft rock stratum condition

A soft rock formation and filling mining technology, which is applied in underground mining, filling, surface mining, etc., can solve the problems of poor safety of mining operations, high support and filling costs, and high labor intensity of workers, so as to ensure the safety of mining operations, Improve the production capacity of the stope and reduce the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

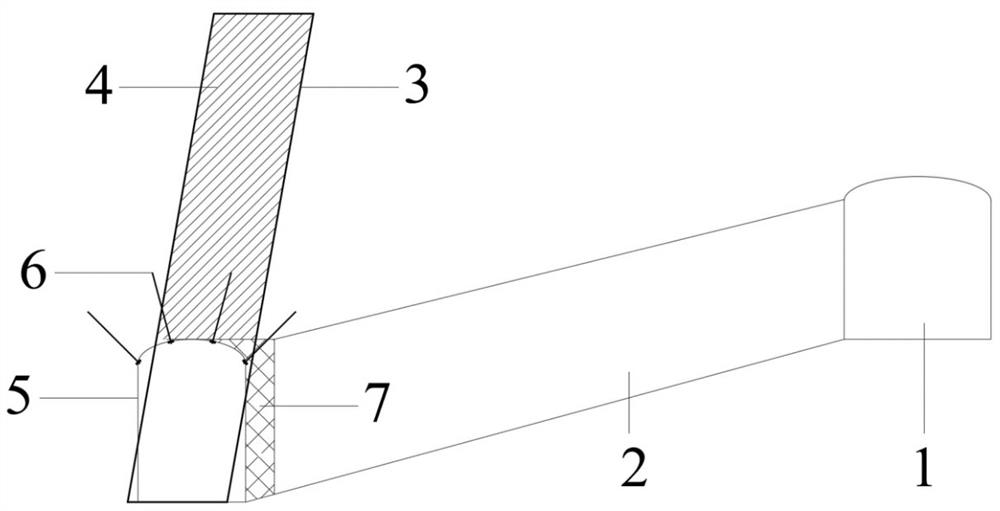

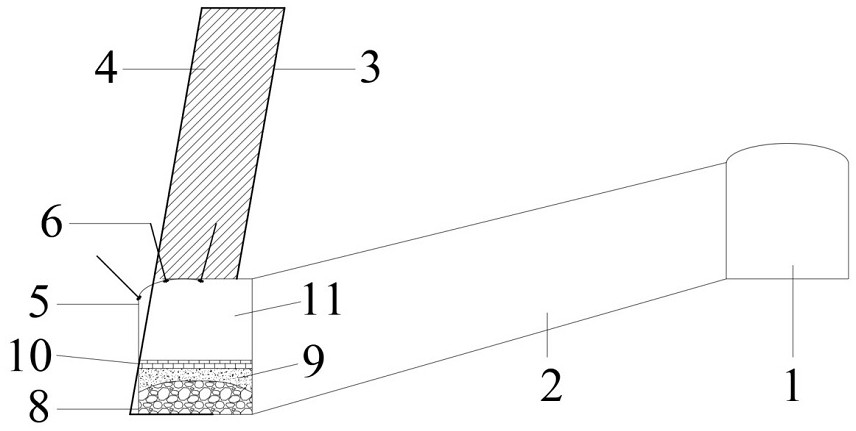

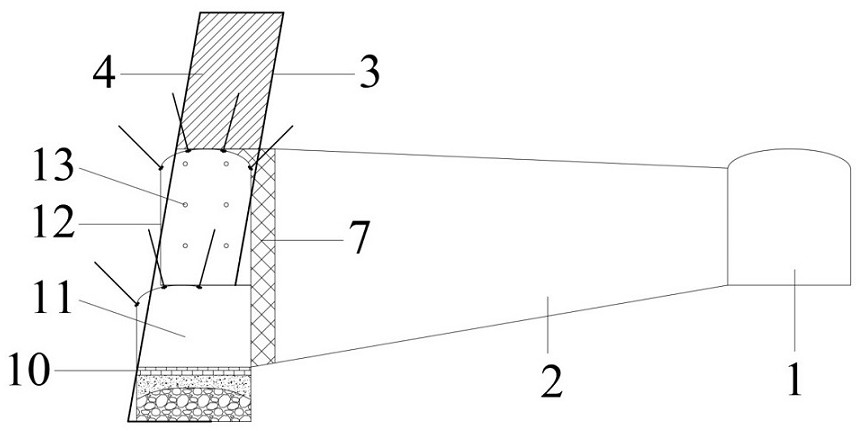

[0029] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

[0030] The mechanized filling mining method of steeply inclined thin ore veins under the condition of a kind of soft rock strata of the present invention adopts the mining standard method of developing the ramp road, connecting the level lanes for segmental transportation, and extracting the ore from the ramp, and transporting the level lanes 1 and 1 in sections from the ramp construction. The layered connecting road 2 is connected with the approach and the chute, and returns to the ore body layer by layer from bottom to top. Specifically include:

[0031] Step 1. Bottom pulling and tunneling: Use a small rock drilling jumbo 14 to drill rock, and after blasting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com