Integrated workstation based on robot cutting, welding and carrying in pipe processing

A technology for handling robots and welding robots, which is applied in metal processing, welding equipment, auxiliary welding equipment, etc., can solve the problems of large footprint, unguaranteed processing accuracy, poor product consistency, etc., and achieves small footprint, Easy to operate and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

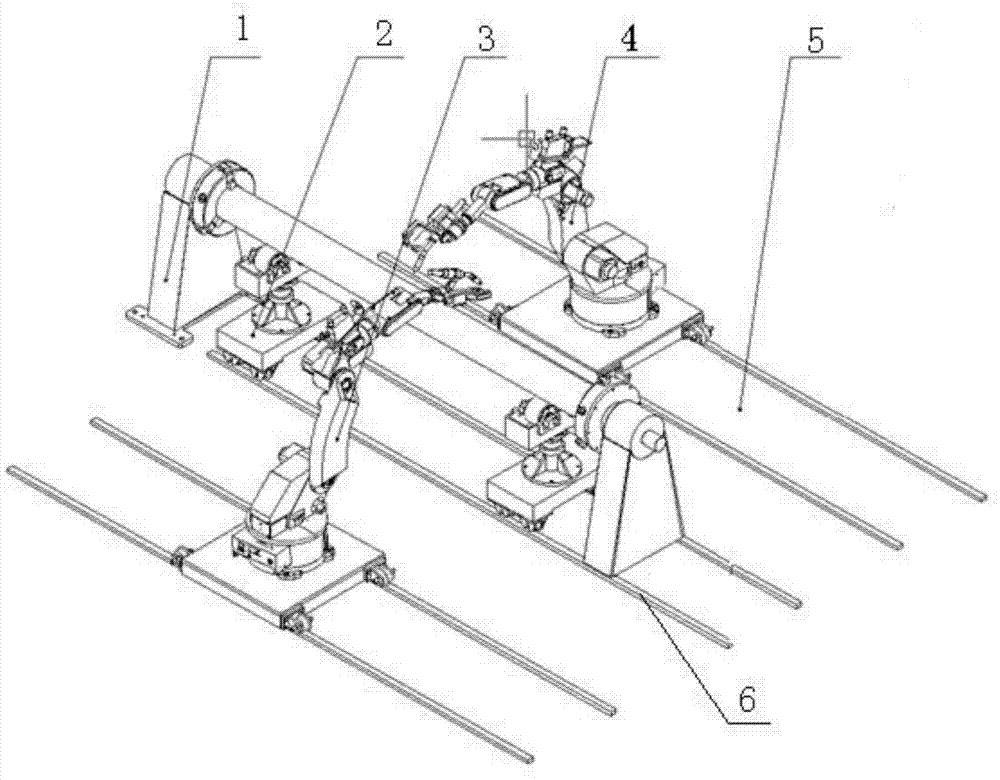

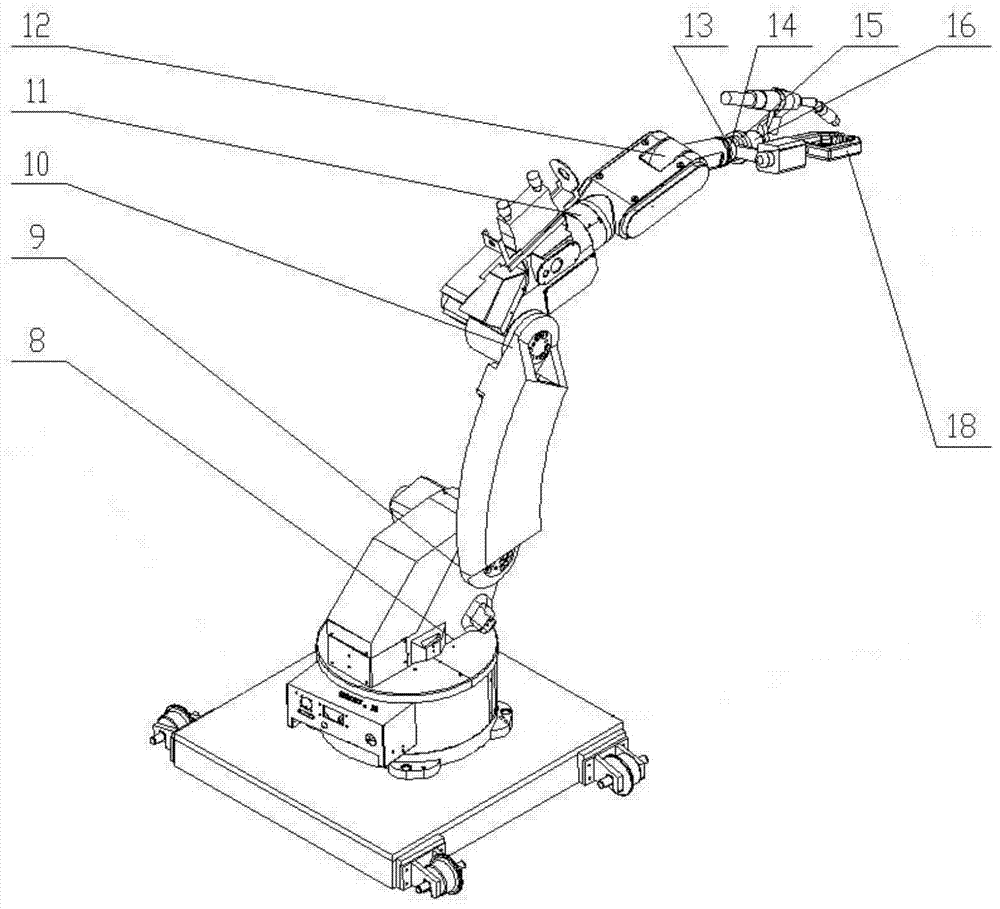

[0019] as attached figure 1 As shown, the integrated workstation of cutting, welding and handling robots based on pipe processing includes head and tail frame positioner 1, movable support 2, welding robot 3, cutting robot 4, middle slide rail 5 and side slide rails 6 The head and tail frame positioner 1 includes a head frame base, a tail frame base and a clamping and fixing device, the head frame base is fixed on the floor at the end of the middle slide rail 5, and the tail frame base is slidably installed on On the middle slide rail 5, the pipeline workpiece is clamped between the clamping and fixing devices on the headstock base and the tailstock base, and the clamping and fixing device is a pneumatic self-centering three-jaw chuck; The movable support 2 includes a sliding base, a lifting drive device and rollers, the sliding base is slidably installed on the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com