Electric precipitation device and scraping device

A technology of electric dust collection and dust collection, which is applied in the direction of electrostatic separation, electrode cleaning, external electrostatic separator, etc., can solve the problems of difficult-to-scratch performance, difficult-to-press margin, unstable dust stripping performance, etc., to achieve improved scraping performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

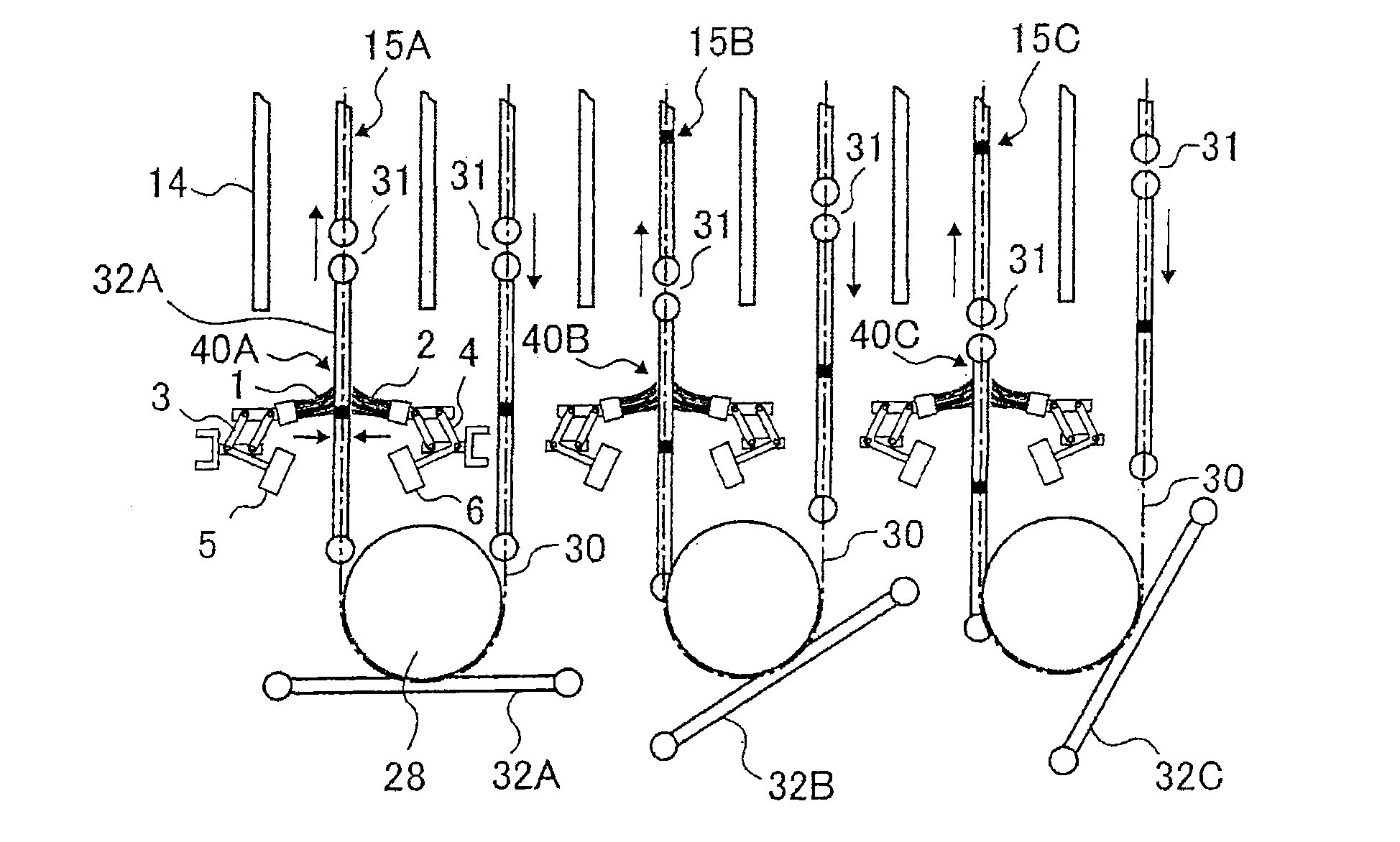

[0059] figure 1 It is a configuration diagram of the lower part of Embodiment 1 of the present invention. As the overall structure of the electrostatic precipitator and described in the above-mentioned background technology column Figure 9 ~ Figure 13 The ones shown are the same, and those given the same symbols as above represent the same elements.

[0060] figure 1 The moving electrodes 15A, 15B, and 15C arranged in the middle make the dust collecting pole plates 32A, 32B, and 32C, which are suspended on the endless chain 30 and descend in a circle, rotate at the position U of the lower roller 28 and change to rise. Scraping mechanisms (brush mechanisms) 40A, 40B, and 40C are respectively arranged at positions sandwiching both surfaces of the dust-collecting electrode plates 32A, 32B, and 32C that have just risen.

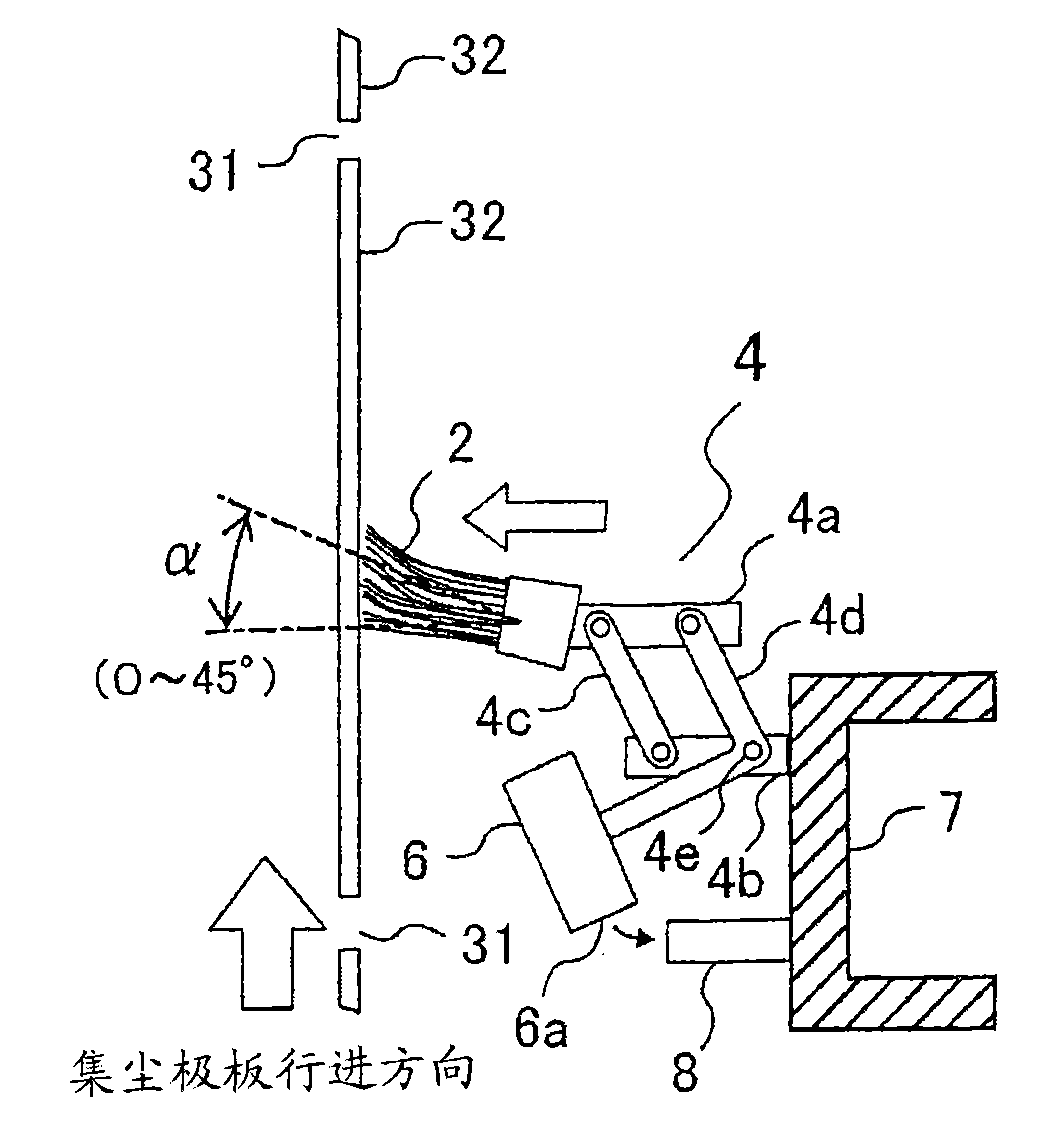

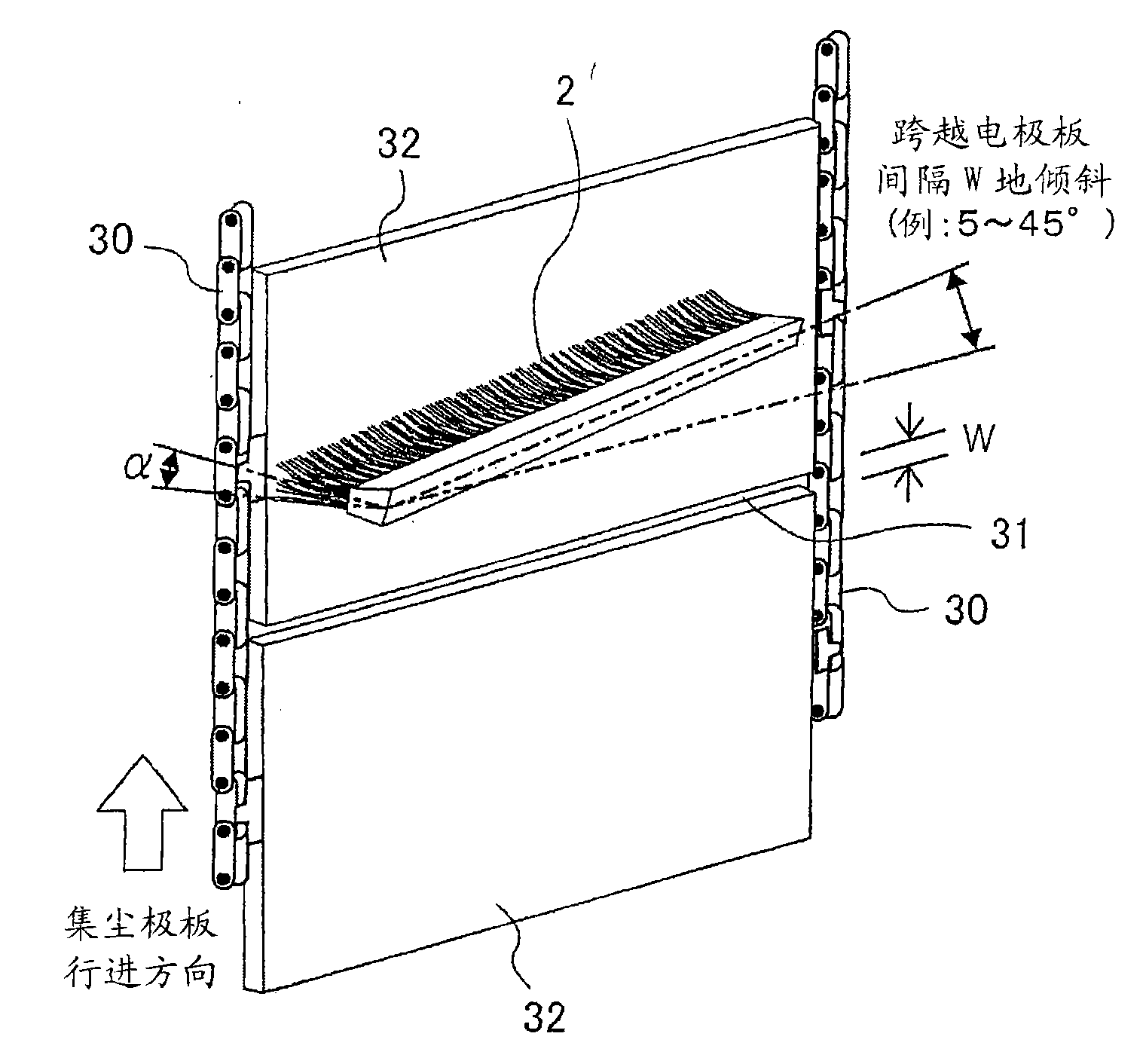

[0061] The brush mechanism 40A has: a pair of long brushes 1, 2 extending in the width direction and in contact with the surface of each dust-collecting pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com