Broadband piezoelectric vibrating scraper, spraying type 3D printing of broadband piezoelectric vibrating scraper, and printing method

A piezoelectric vibration and 3D printing technology, applied in 3D object support structure, coating device, processing and manufacturing, etc., can solve the problem of easy residual air bubbles, affecting the quality of slurry molding, and uneven surface flatness and surface finish of sprayed slurry. Good and other problems, to achieve the effect of reducing friction and high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

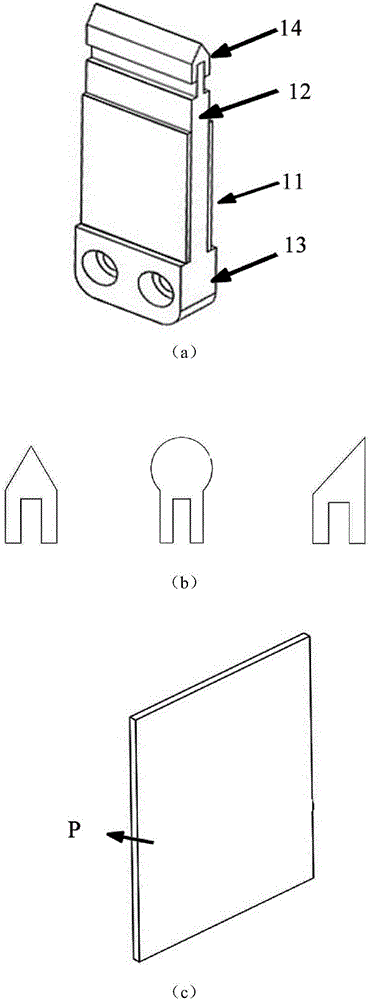

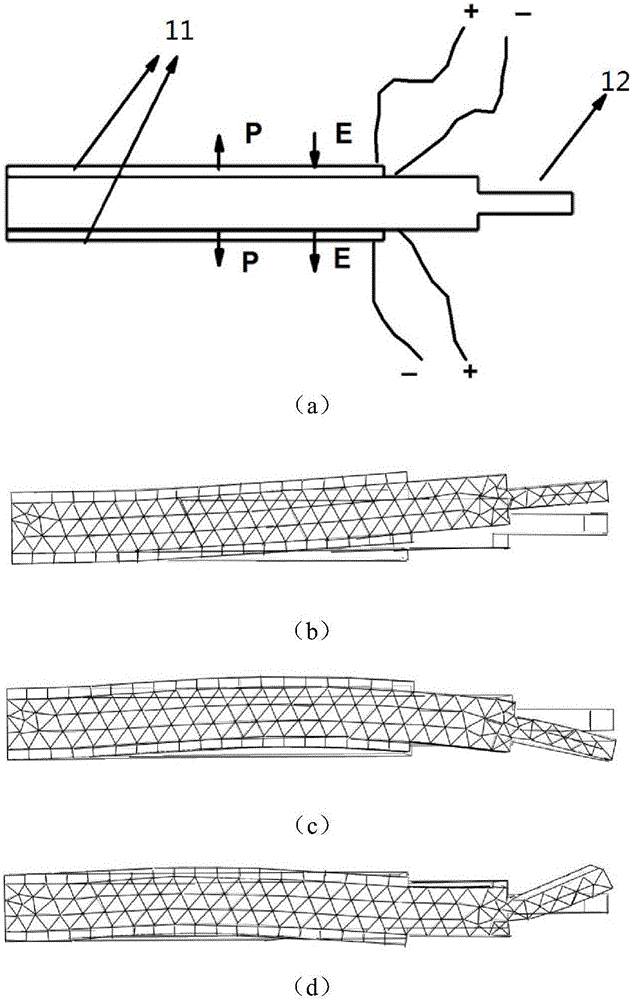

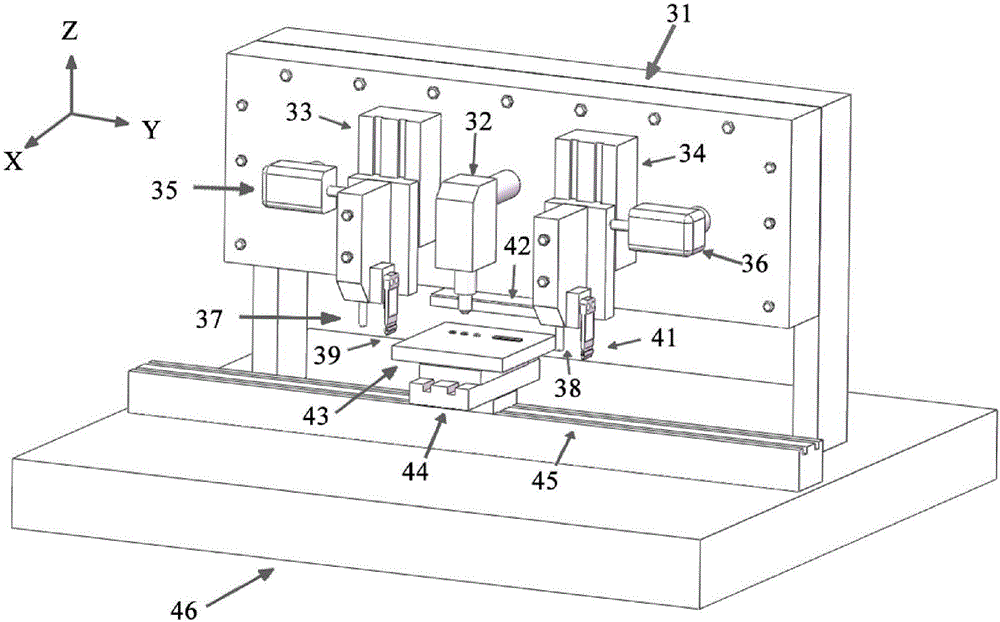

[0038] Such as figure 1 Shown in (a), the piezoelectric vibrating scraper of the present embodiment comprises: piezoelectric element 11, vibrating blade 12, handle of a knife 13 and cutter head 14; Wherein, piezoelectric element 11 is bonded on vibrating blade 12 by epoxy resin respectively On both sides of the surface, a layered composite structure of sandwich structure is formed; the knife handle 13 of the vibrating blade is used to fix the scraper; the top of the vibrating blade 12 is equipped with a knife head 14; the piezoelectric element 11 is connected to an external drive system. Such as figure 1 As shown in (b), the top of the vibrating blade can be equipped with cutter heads of different shapes, such as triangular, cylindrical or wedge-shaped cutter heads. Such as figure 1 As shown in (c), the polarization of the piezoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com