Dust recycling system

A technology of dust recovery and dust removal box, applied in the direction of filter screen, grille, dispersed particle filtration, etc., can solve the problems of low dust recovery efficiency and low dust removal efficiency, and achieve good dust scraping effect, high dust removal efficiency and good effect. Effect

Active Publication Date: 2018-10-09

GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

View PDF7 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

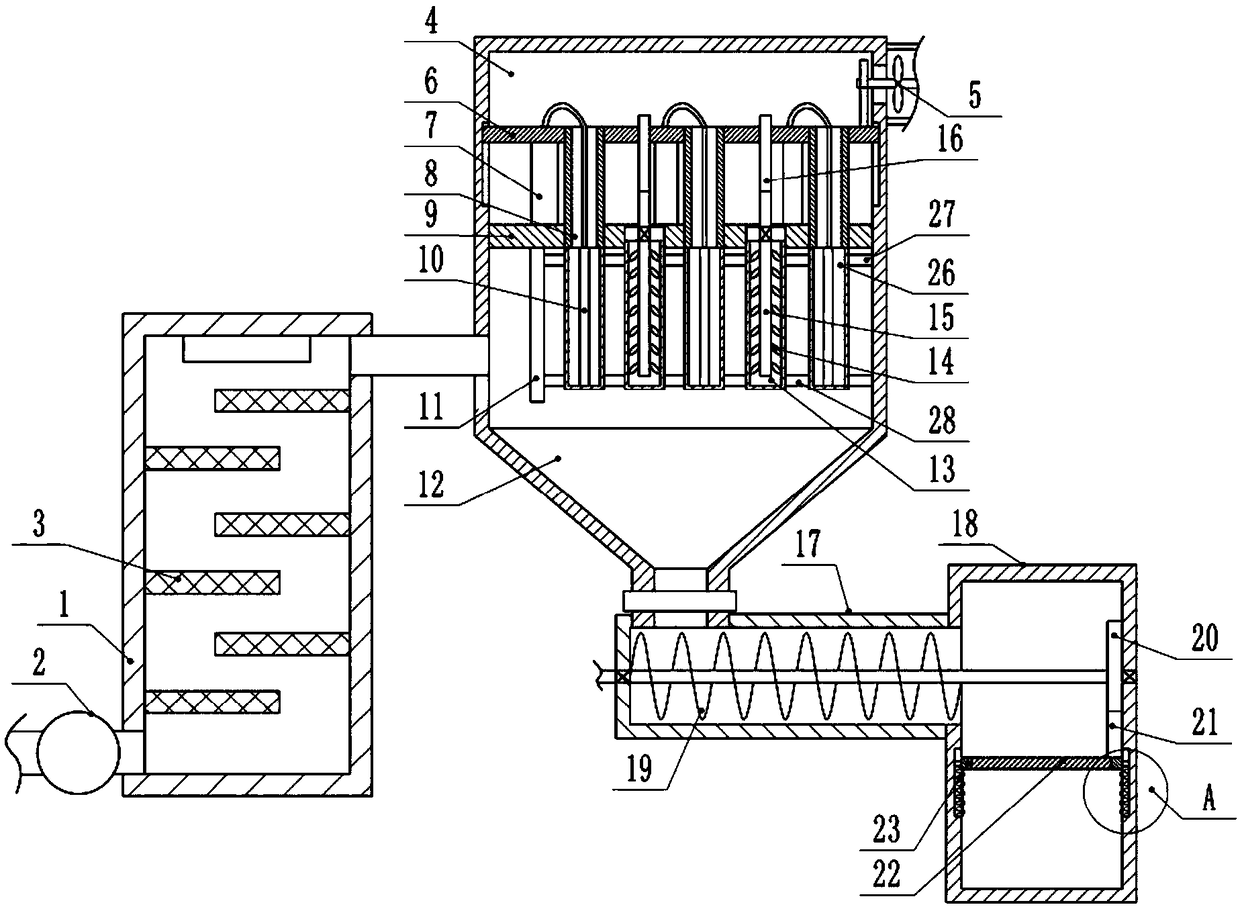

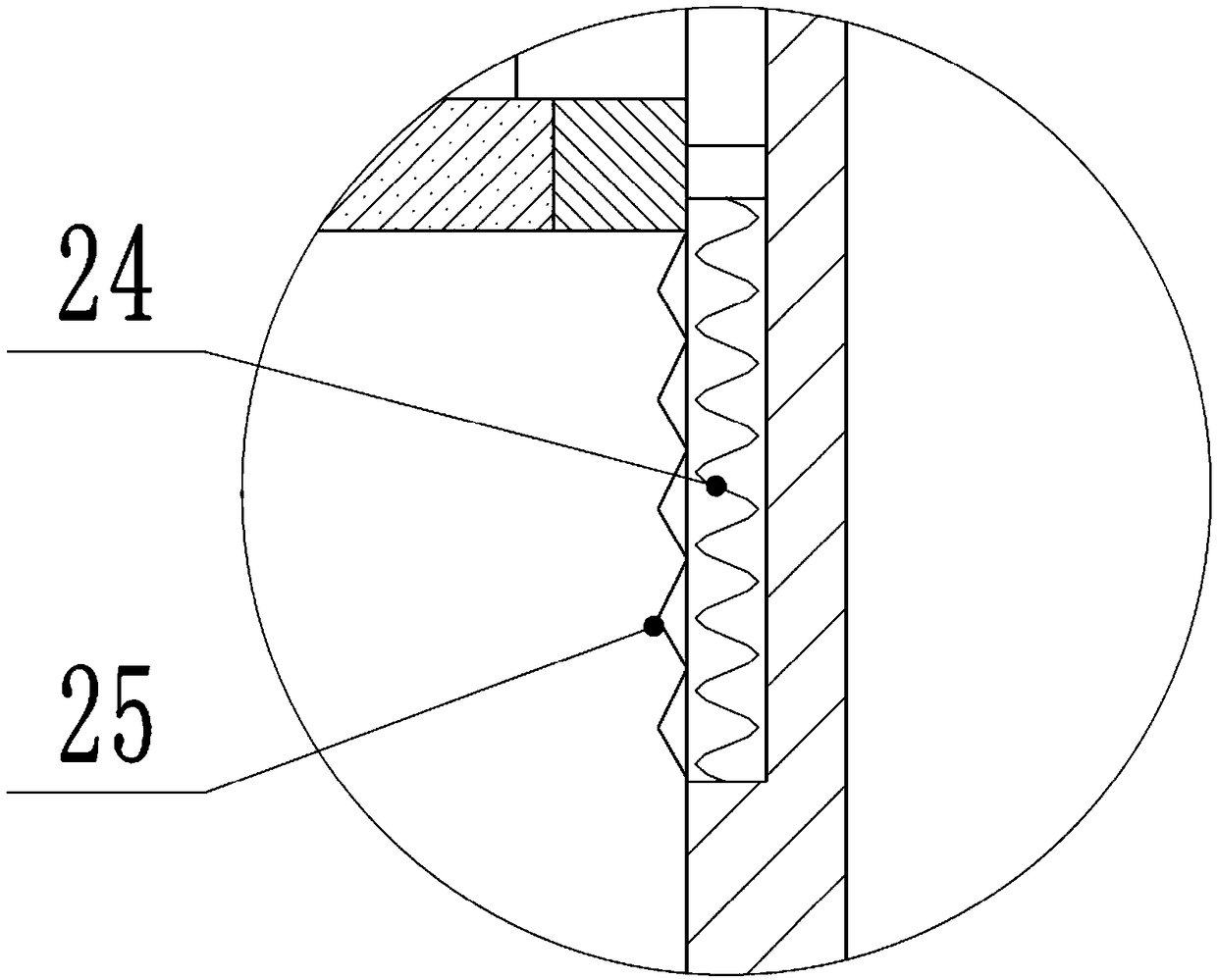

The invention belongs to the technical field of environmental protection systems, and particularly discloses a dust recycling system. The dust recycling system comprises a cooling unit, a dust removalunit and a recycling unit, wherein the dust removal unit comprises a dust removal box; a partition plate divides the dust removal box into an upper part, namely an air purification chamber and a lower part, namely a filter chamber; a plurality of fixed filter bags and movable filter bags are alternately arranged in the filter chamber; an air exhaust mechanism is arranged in the air purification chamber; the upper ends of the movable filter bags are connected with a lifting mechanism; the lifting mechanism is connected with the air exhaust mechanism; the air exhaust mechanism works to drive the movable filter bags to rise up and fall off through the lifting mechanism; upper scraper blades are arranged at the upper parts of the movable filter bags; lower scraper blades are arranged at the lower parts of the fixed filter bags; the insides of the fixed filter bags are connected with rotating shafts, driven by the lifting mechanism, in a rotatable manner; flexible blades are arranged on the rotating shafts; the recycling unit comprises a material feeding mechanism and a screening mechanism; the material feeding mechanism is communicated with an ash bucket; and the screening mechanism is communicated with the material feeding mechanism and is located at the end, far away from the ash bucket, of the material feeding mechanism. The dust recycling system realizes ash cleaning of the filter bags in a dust filtering process, and is high in dust removal efficiency and high in dust recycling efficiency.

Description

technical field [0001] The invention belongs to the technical field of environmental protection systems, and in particular relates to a dust recovery system. Background technique [0002] In my country's metallurgy, building materials, chemical industry, and electric power industries, there are a large number of industrial furnaces and kilns, which generate a large amount of dust-containing flue gas during production and operation. According to the provisions of the National Environmental Protection Law, the flue gas must be dedusted and purified to achieve standard discharge. The dust must be Recycle. The dust removal and purification of flue gas is carried out by bag filter. When there is a lot of dust on the filter bag during the dust removal process, the filter resistance of the dust will be large, and it is difficult to operate normally. The filter bag must be cleaned of dust. The existing bag Type dust collectors usually use the recoil of compressed gas to clean the fi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D50/00B01D46/04B01D46/06B01D46/48B01D53/26B07B1/28

CPCB01D46/023B01D46/04B01D46/06B01D46/48B01D53/26B07B1/28B01D2258/0283B01D50/20

Inventor 张朝友赵明伦袁志勇袁世国

Owner GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com