Printing knife rest system based on intaglio printing and working method thereof

A gravure printing and working method technology, applied in gravure rotary printing machines, general parts of printing machinery, printing and other directions, can solve the problems of uneven surface polishing, affecting image and text transfer, etc., and achieve fast drying speed and good scraping effect. , Guarantee the effect of scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

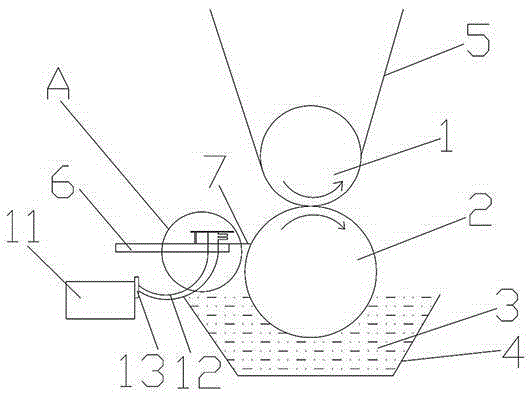

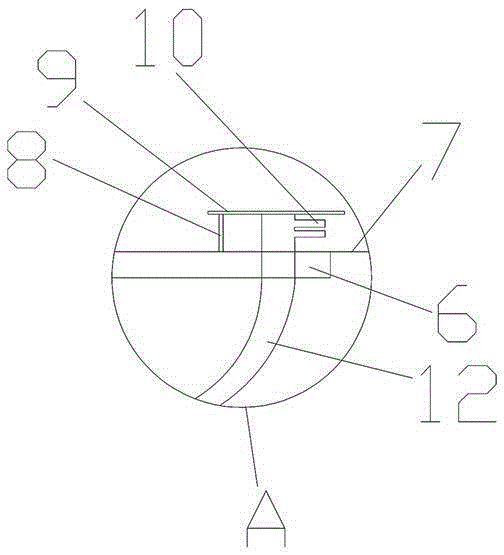

[0028] Such as figure 1 , figure 2 As shown, a printing knife holder system based on gravure printing in this embodiment includes: embossing roller 1, gravure printing roller 2, ink 3, ink fountain 4 and printing paper 5, and also includes: knife holder 6, doctor blade 7. Support 8, slide rail 9, air nozzle 10, air pump 11, air pipe 12 and regulating valve 13; the ink fountain 4 contains ink 3, the bottom of the gravure printing roller 2 is immersed in the ink 3, and the embossing roller 1 presses the printing paper 5 is sent to the junction of the embossing roller 1 and the gravure printing roller 2; the left side of the gravure printing roller 2 is provided with a knife holder 6, and the front end of the knife holder 6 is provided with a scraper blade 7, which is pressed against the gravure printing On the roller 2; the slide rail 9 provided above the knife rest 6 is fixed by the bracket 8; the air pipe 12 passes through the knife rest 6 and connects with the slide rail 9,...

Embodiment 2

[0039] Described a kind of printing knife post system based on gravure printing, its structure is identical with the structure in embodiment 1, and its mode of operation is as follows:

[0040] (1) The gravure printing roller 2 rotates clockwise to apply the ink 3 in the ink fountain 4 to the chrome-plated surface of the gravure printing roller 2 and the cells;

[0041] (2), the scraper blade 7 pressed against the gravure printing roller 2 scrapes off the excess ink 3 on the gravure printing roller 2 except for the cells, wherein the length of the scraper blade 7 is 31 mm;

[0042] (3) The air pump 11 sends the air flow to the air nozzle 10 through the air pipe 12, wherein the regulating valve 13 can adjust the size of the air flow, and the air pipe 12 moves to the middle of the slide rail 9;

[0043] (4) After the scraper blade 7 scrapes off the ink 3 in the non-graphic position on the gravure printing roller 2, the airflow blown out by the air nozzle 10 will dry the ink 3 stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com