Vacuum concentrator

A vacuum concentrator and concentration tank technology, applied in evaporator accessories, chemical instruments and methods, evaporation and other directions, can solve the problems of scaling formation and the reduction of heat transfer efficiency of the concentration tank, so as to prevent the reduction of heat transfer efficiency and reduce heat The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

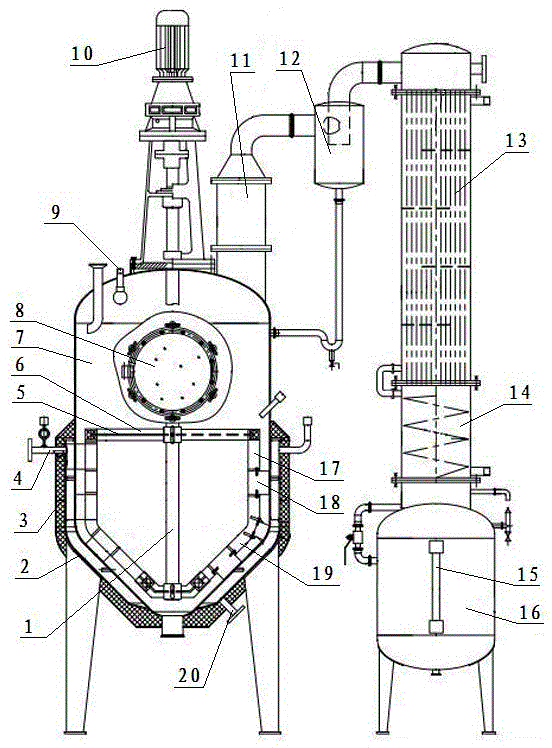

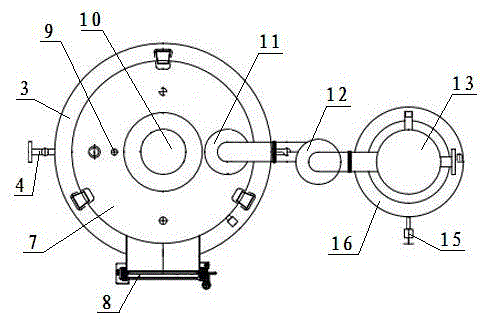

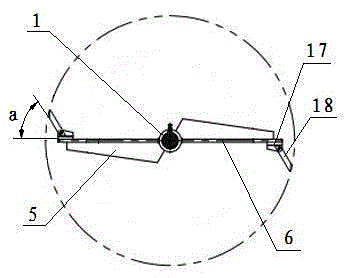

[0017] Such as figure 1 , figure 2 The shown vacuum concentrator includes a concentration tank 7 with a jacket 2 on the outside. The jacket 2 is equipped with a water vapor connecting pipe 4 and a condensed water discharge pipe 20. An insulation layer 3 is installed on the outer surface of the jacket 2. Layer 3 has thermal insulation cotton and a guard plate covering the outer surface of the thermal insulation cotton; the steam outlet of the concentration tank 7 is connected with a vapor-liquid separator 12, a condenser 13, a cooler 14 and a liquid collector 16 in sequence, and the condenser of this embodiment 13 is a shell and tube condenser; a demister 11 is installed between the concentration tank 7 and the vapor-liquid separator 12, and a liquid level gauge 15 is installed on the liquid collector 16; The stirring device connected, the stirring device comprises a rotating shaft 1 and two stirring paddles 5 fixed on the rotating shaft 1, a rotating frame is housed on the r...

Embodiment 2

[0020] The difference between this embodiment and Embodiment 1 is that the angle a between the scraper 18 and the cross bar 6 is 55 degrees. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com