Corn threshing device

A corn threshing and chassis technology, which is used in threshing equipment, applications, agricultural machinery and implements, etc., can solve problems such as low efficiency, scratches on the operator's hands, and corn kernels scattered on the ground, etc. The effect of low probability and good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

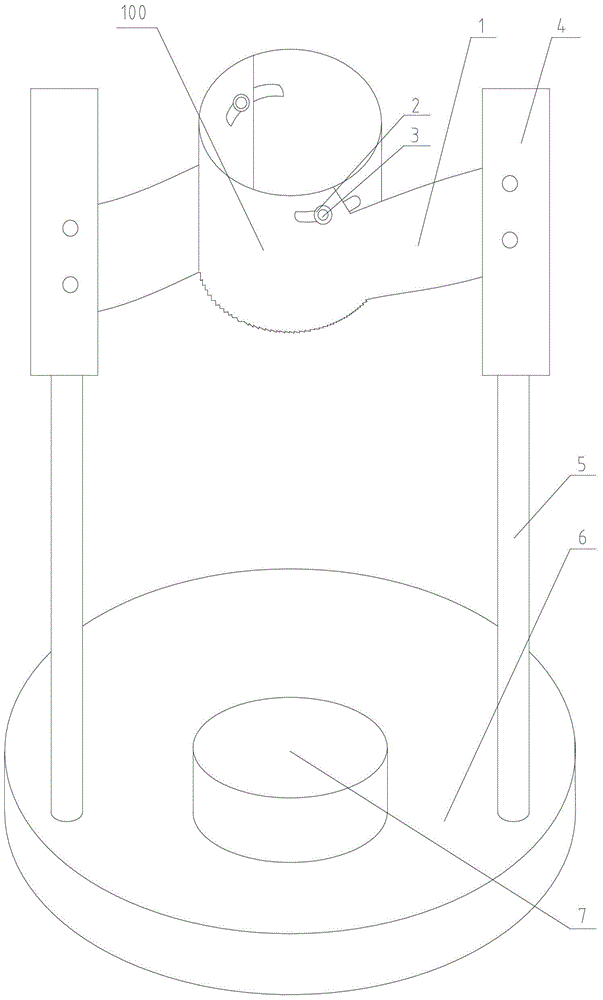

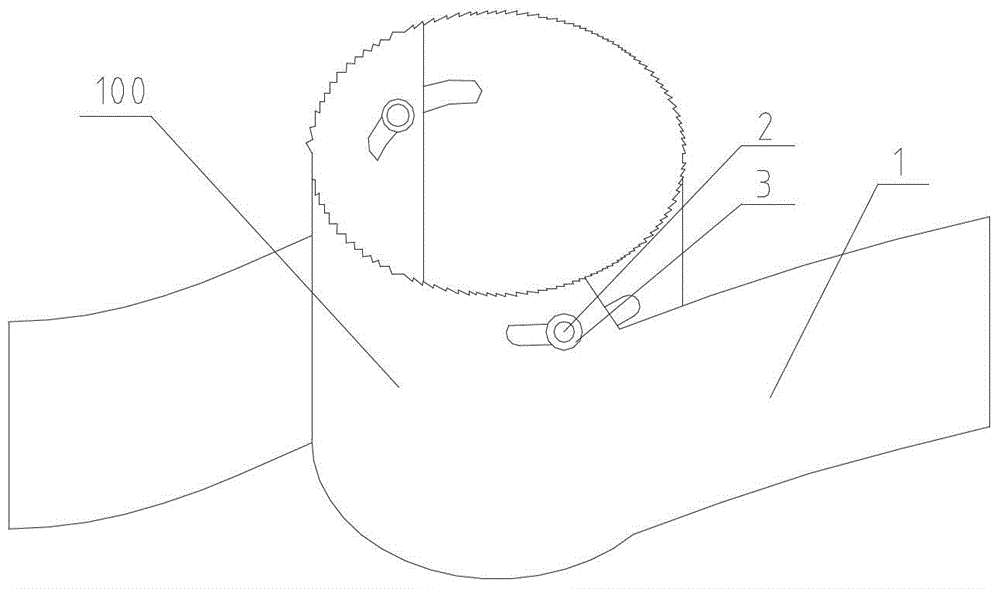

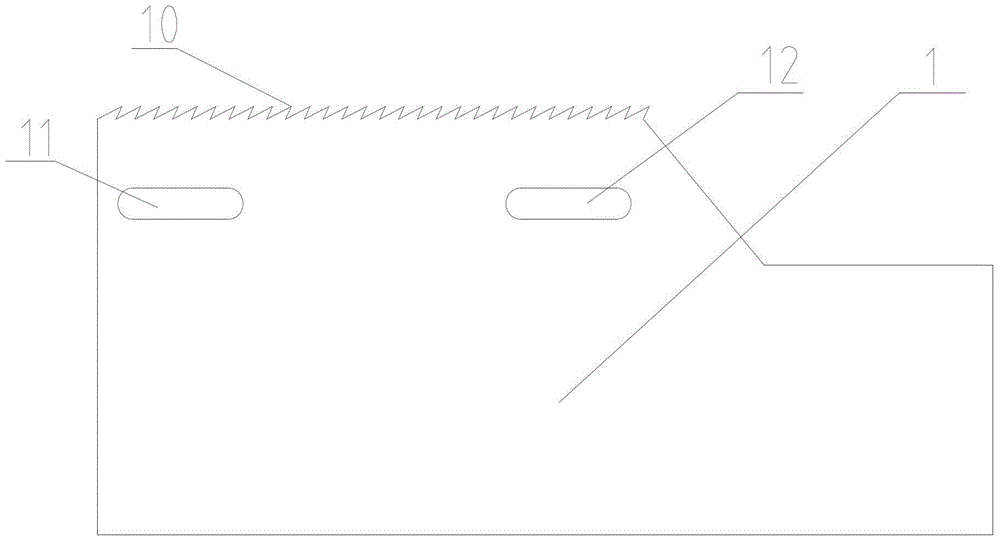

[0019] Such as figure 1 , figure 2 , image 3 As shown, the corn threshing device of the present embodiment includes a chassis 6, and two slide bars 5 are vertically fixed on the center line of the chassis 6 vertically to the chassis 6, and each slide bar 5 is covered with a handle 4, and the handle 4 can be placed on the The sliding bar 5 slides up and down, and a cylindrical knife set 100 is fixed between the two handles 4. The cylindrical knife set 100 includes two rectangular blades 1, and one side of the blade 1 is a serrated edge 10 One end of the blade 1 has a first fixing hole 11, and the middle section of the blade 1 has a second fixing hole 12, and the first fixing hole 11 and the second fixing hole 12 are elongated, so that the first fixing hole 11 and the second The fixing hole 12 is close to the sawtooth edge 10, and the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com