Mixing barrel with water flushing scraper blade for chemical use

A mixing tank and scraper technology, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of high energy consumption of mixers, large stirring resistance, and high heating of the inner wall of the mixing tank. Achieve the effect of improving scraping efficiency and reducing scraping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

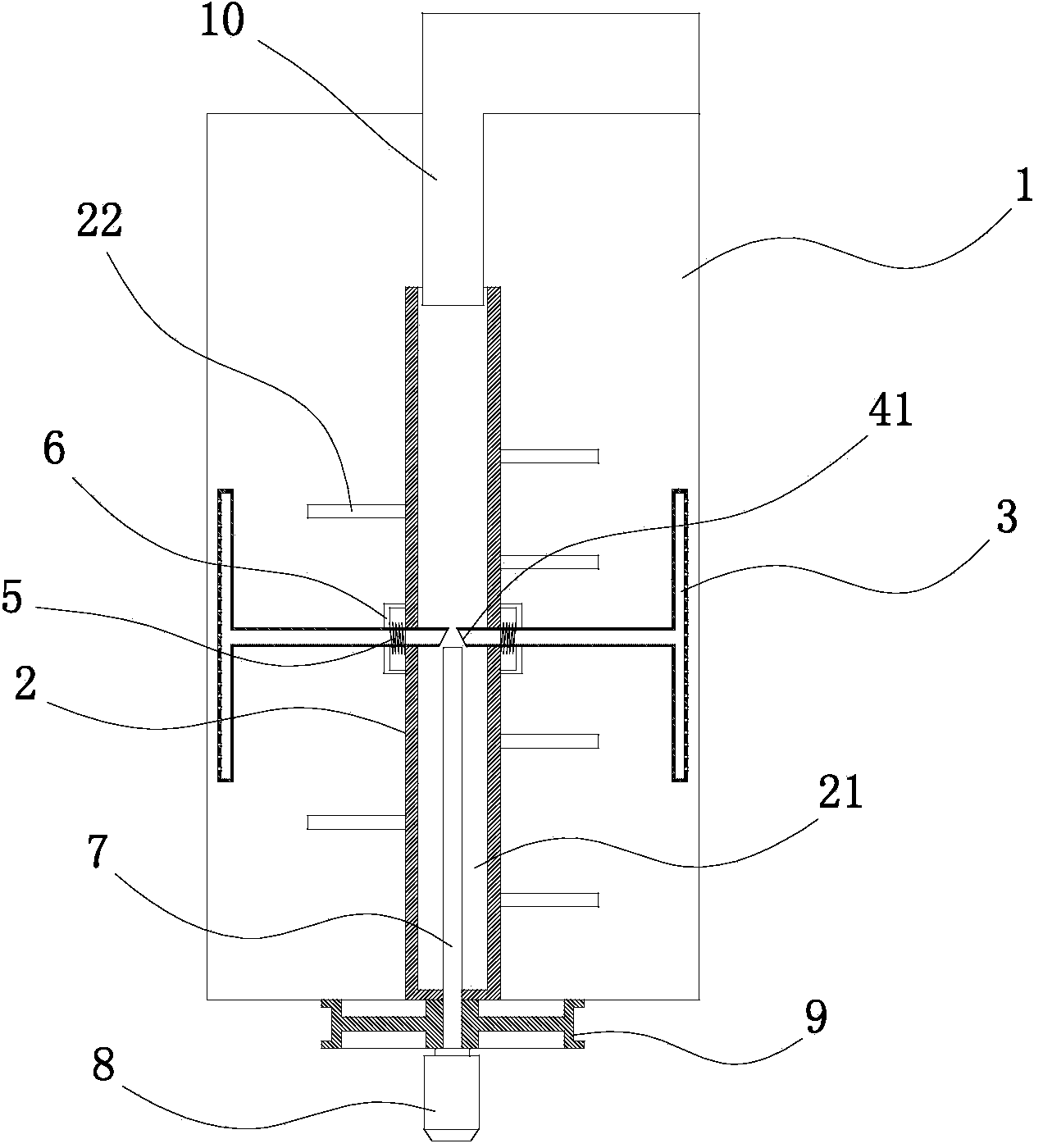

[0016] Such as figure 1 As shown, the chemical mixing tank with a water flushing scraper in this embodiment includes a mixing tank 1, an agitating shaft 2 installed in the mixing tank 1, and a scraper is installed on the agitating shaft 2 through a connecting rod 4 3. The stirring shaft 2 is a tubular structure with a central through hole 21. The upper end of the stirring shaft 2 has an opening, and its lower end is fixedly connected with a pulley 9, which is connected to the motor through a timing belt; The end surface is fixedly connected with a water inlet pipe 10, and the water outlet end of the water inlet pipe 10 extends into the central through hole 21 of the stirring shaft 2, and its water inlet end is connected with an external water source; The rod is axially fixedly connected with a push rod 7, and the push rod 7 runs through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com