Detinning processing method of chip and chip detinning machine applying method

A processing method and chip technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of waste of solder, high wind power of air knives, and the efficiency of tin removal machines needs to be improved, so as to achieve less loss of solder and recycling. The effect of high rate and high tin scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

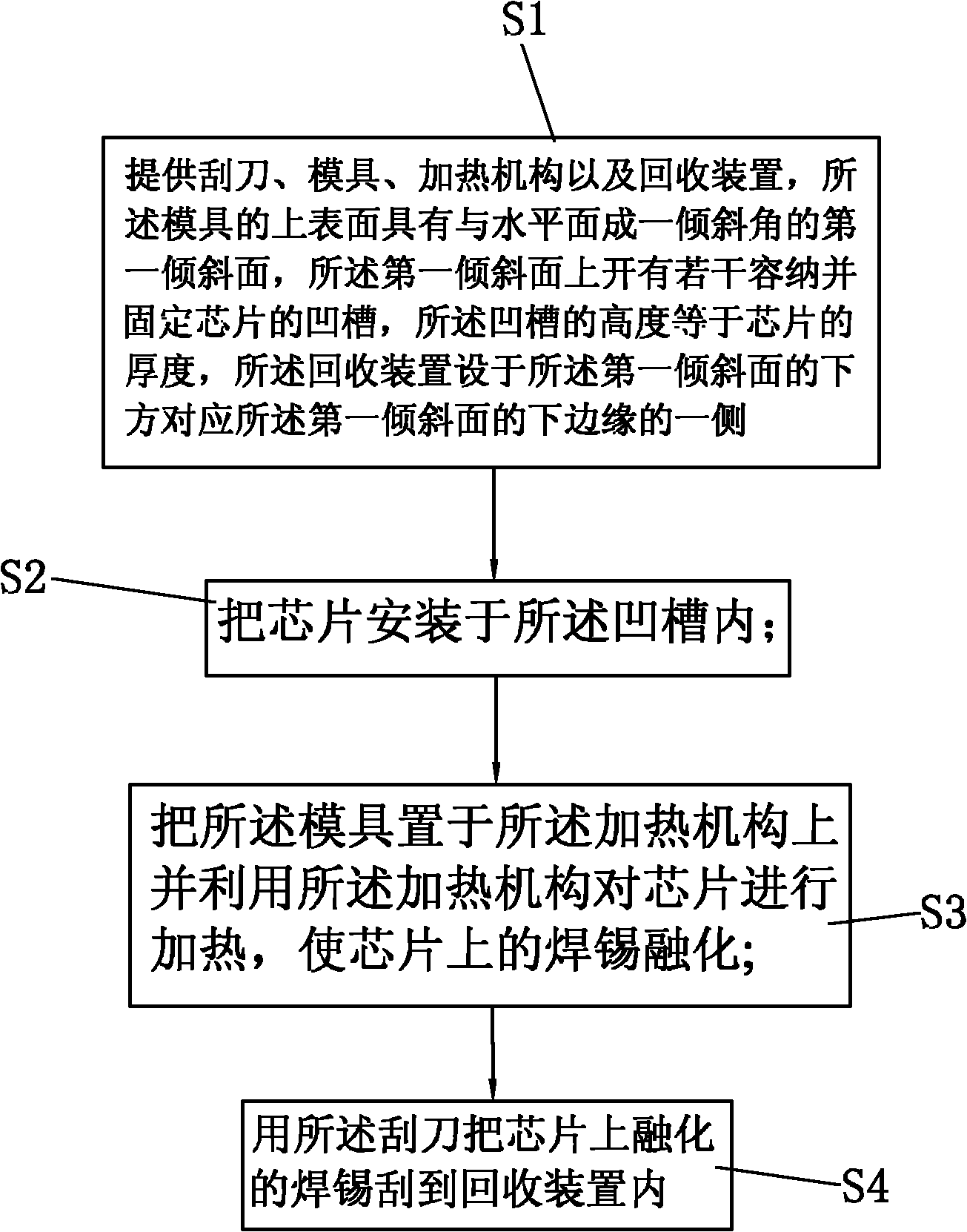

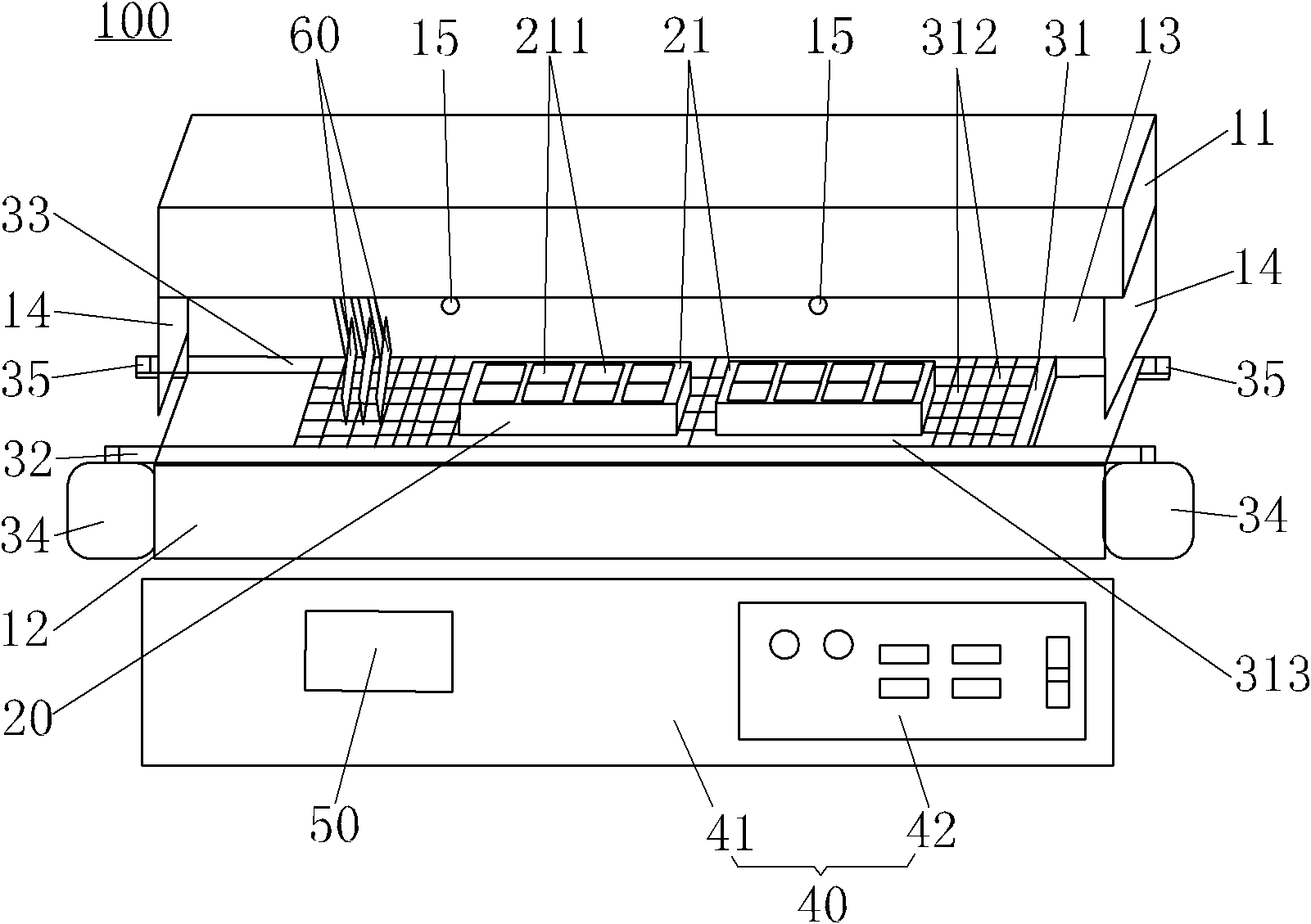

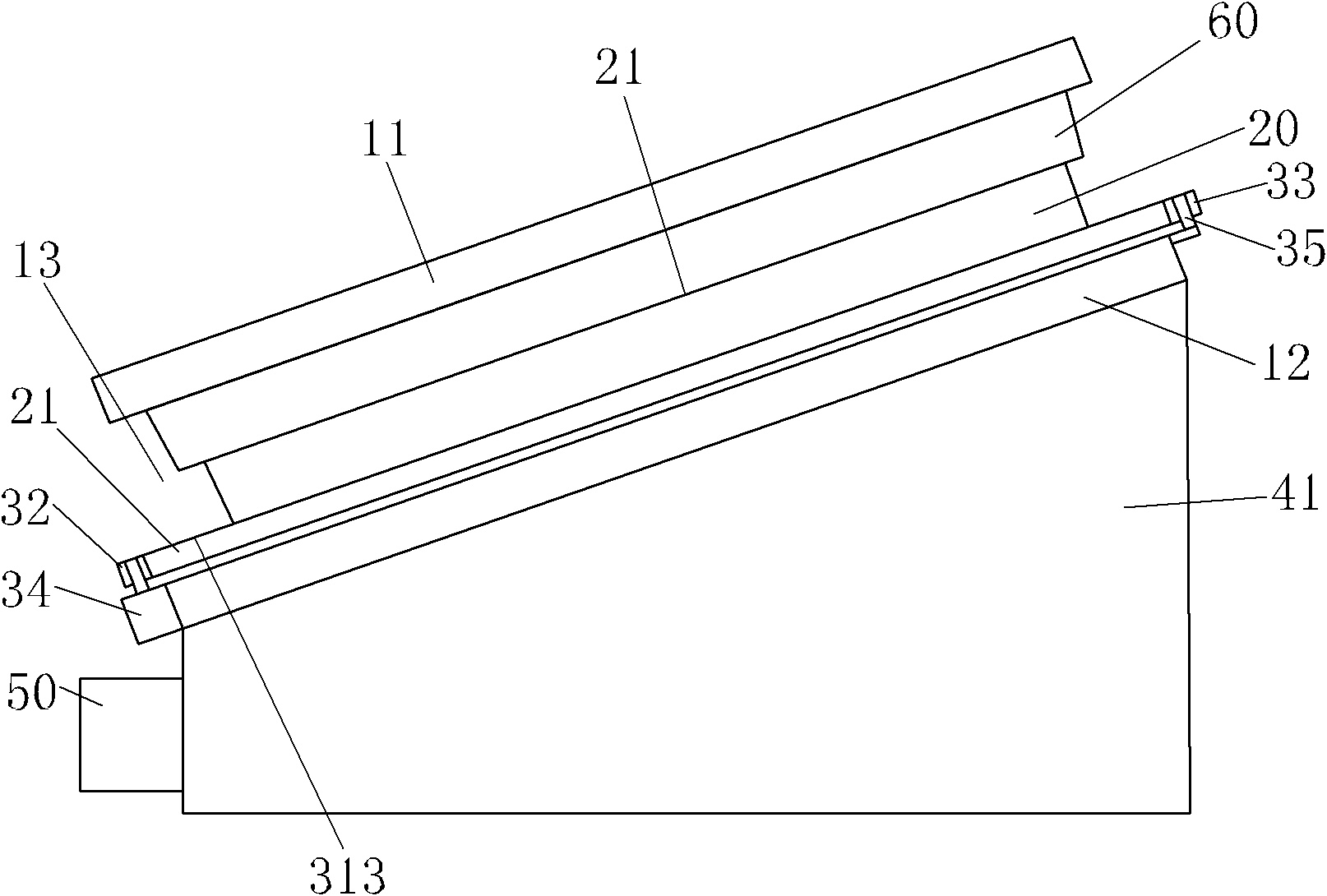

[0029] refer to figure 1 , a processing method for removing tin from a chip, comprising the following steps, S1: providing a scraper, a mold, a heating mechanism, and a recovery device. In this embodiment, the scraper is made of soft plastic to prevent the scraper from scratching the circuit board of the chip. , the upper surface of the mold has a first inclined surface with an inclined angle with the horizontal plane, the inclined angle is between 25 degrees and 30 degrees, and a plurality of grooves for accommodating and fixing chips are opened on the first inclined surface, The height of the groove is equal to the thickness of the chip, and the recovery device is arranged on the side below the first inclined surface corresponding to the lower edge of the first inclined surface; S2: install the chip in the groove ; S3: Put the mold on the heating mechanism and use the heating mechanism to heat the chip to melt the solder on the chip. In this embodiment, the heating mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com