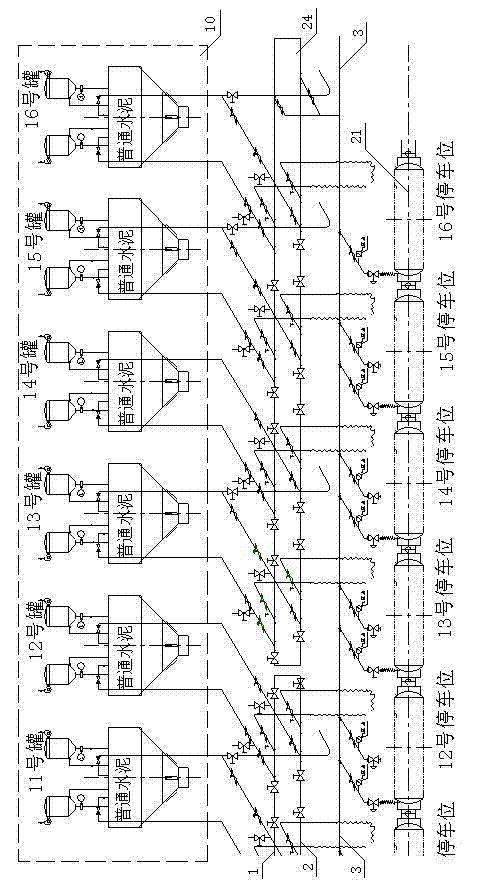

Loose-packed gel material parallel ash-unloading system

A cementing material and parallel technology, applied in the field of transportation, can solve problems such as the inability to realize the "many-to-many" ash unloading method, clogging of the ash loading pipe, long ash unloading pipeline, etc., so as to improve reliability and safety, reduce The workload and quality are guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

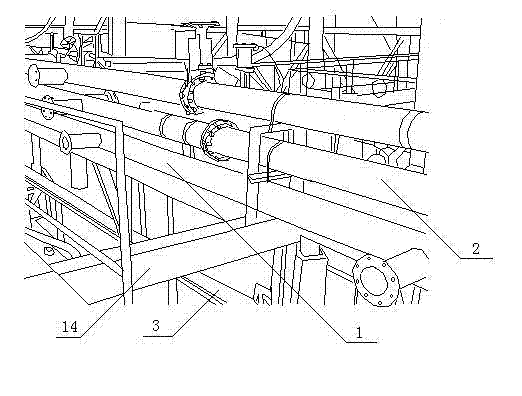

Method used

Image

Examples

Embodiment 1

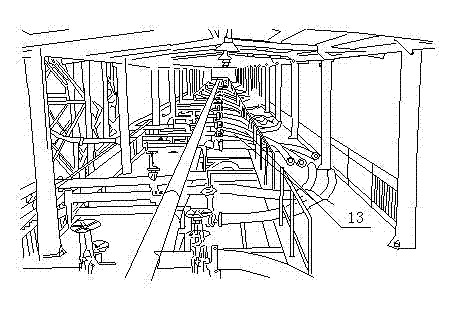

[0067] Railway tank car unloading:

[0068] When the train arrives, manually connect the ash unloading quick connector on the train tank, press the start button box next to it or use the walkie-talkie to notify the on-duty personnel in the central control room to issue an instruction to unload the ash → turn on the tank top vacuum cleaner device to work → when the pressure When the normal value is reached, open the electric control valve of the main line at the corresponding position to deliver material to the cementitious material tank → start ash unloading. After the ash unloading is completed and stopped (manually confirmed or the tank is filled with cementitious materials), the work of the above equipment and facilities will be stopped in reverse according to the above requirements.

[0069] Car ash unloading:

[0070] When it is determined that the car needs to load ash, send an instruction → start the cooling water tower → cooling water pump → control cold dryer → contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com