Rapid tin planting device for BGA chip

A fast, chip-based technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as displacement of tin-planting nets, mutual adhesion of solder, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

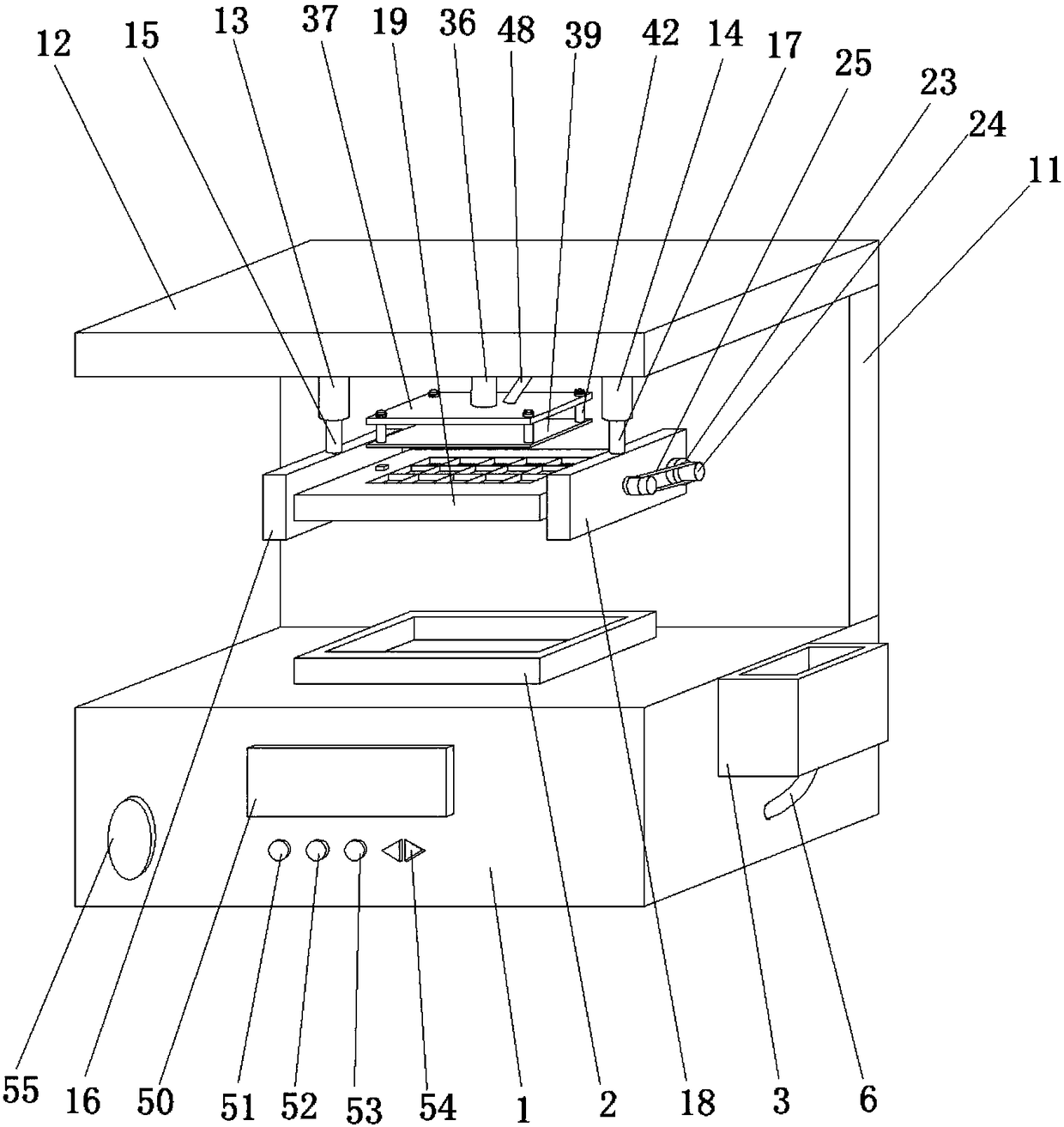

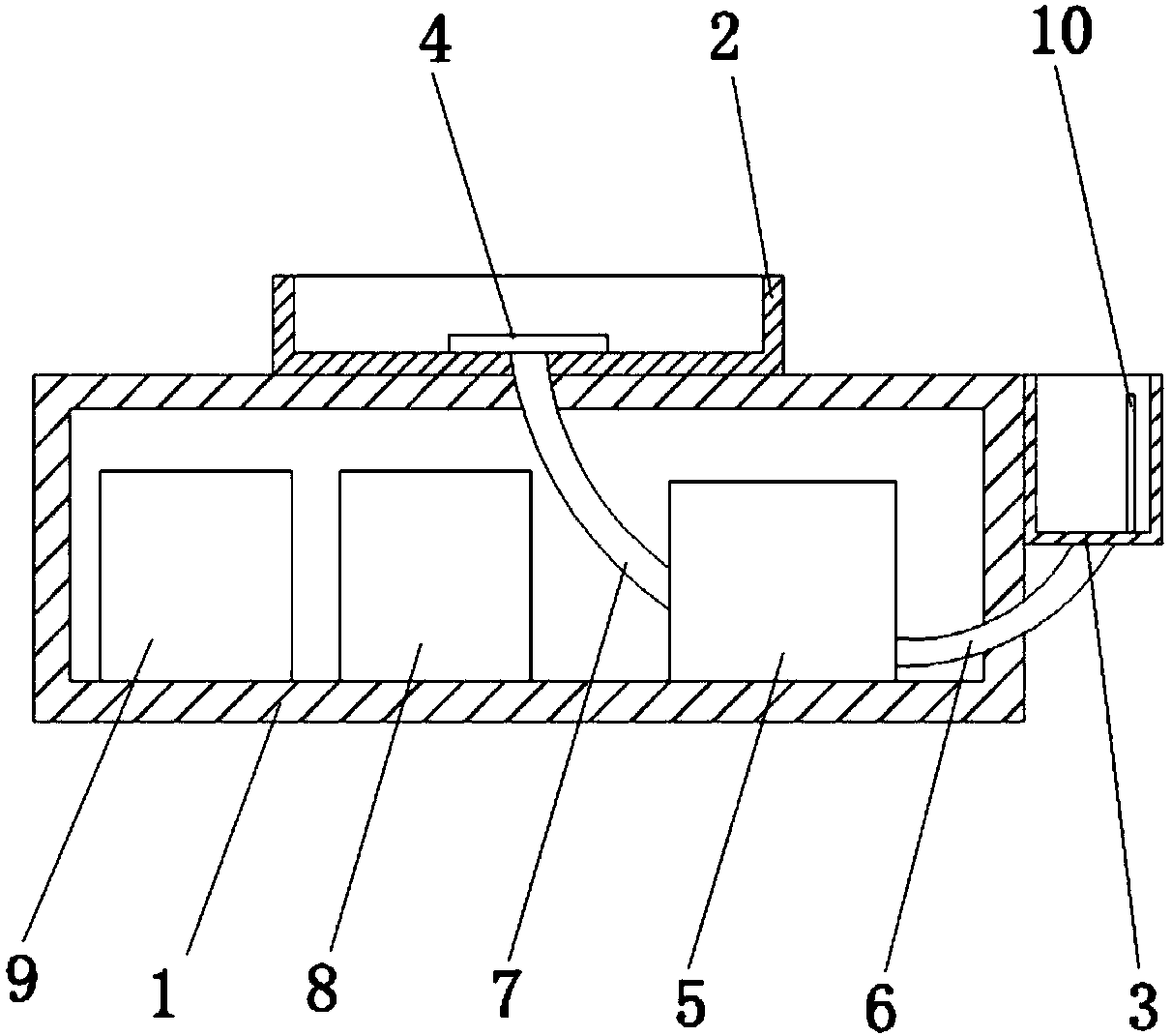

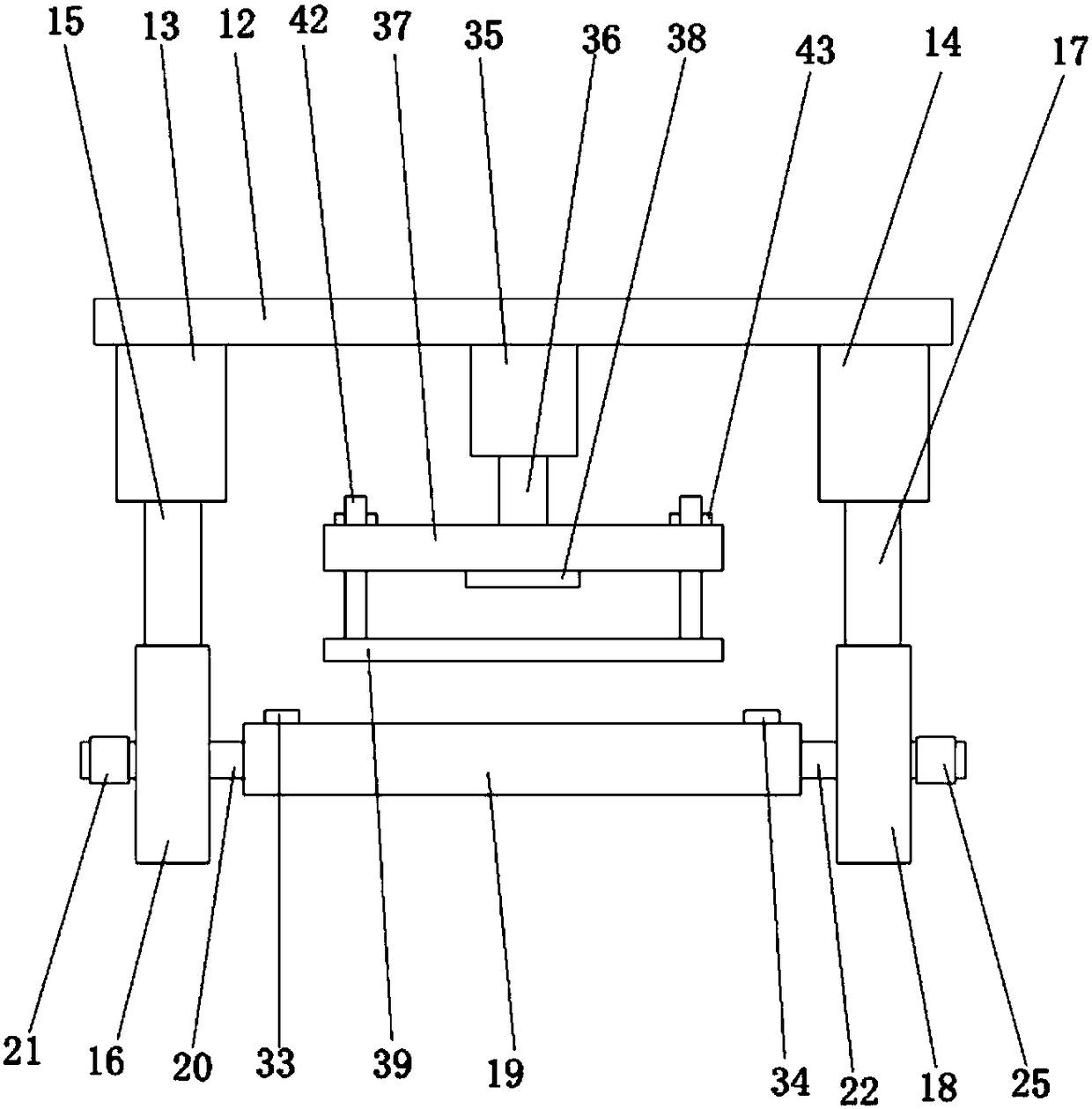

[0026] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] combine Figure 1 to Figure 7 , a fast tin planting device for BGA chips, including a device body, the device body includes a console 1, one side of the console 1 is provided with a tin stripping liquid tank 3, the tin stripping liquid tank 3 is an open structure at the upper end, and the tin stripping liquid The side wall of the liquid tank 3 is connected with the side wall of the console 1, the top of the console 1 is centered with a waste liquid pool 2, and the waste liquid pool 2 is an open structure at the upper end, and the center of the bottom of the waste liquid pool 2 is provided with a second A sprinkler head 4, the console 1 is a hollow structure, the console 1 includes a console shell, the bottom inside of the console shell is provided with a first water pump 5, and the first water pump 5 includes a first water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com