Photogravure press and squeegee device thereof

A technology of gravure printing machines and printing rollers, which is applied in the direction of gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve problems such as missing printing, white spots in graphics and text, and affect product quality, so as to reduce the degree of damage, High ink scraping efficiency and good ink cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

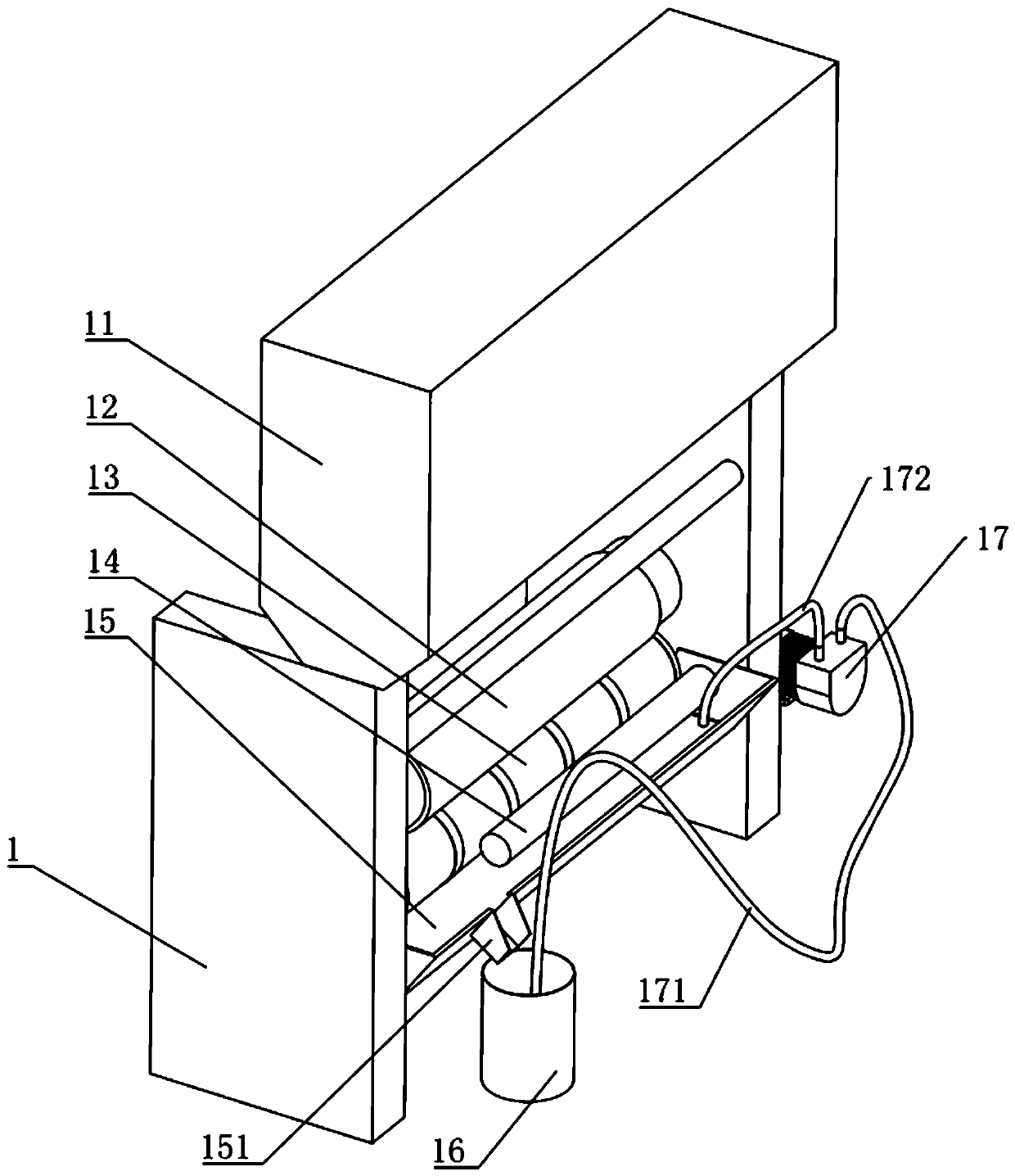

[0045] Embodiment one, a kind of scraping device of gravure printing machine, such as figure 1 As shown, it includes a frame 1, an oven 11 is arranged above the frame 1, an embossing roller 12 of rubber material is arranged between the frame 1, and a printing roller 13 is arranged under the embossing roller 12, and the printing roller 13 and the embossing roller There is a very small gap between the 12, the printing roller 13 is provided with a gravure plate for printing pictures and texts, an ink roller 14 is arranged against the printing roller 13, an ink pan 15 filled with ink is arranged under the ink roller 14, and The ink roller 14 is immersed in ink.

[0046] One side of the ink tray 15 is provided with an oil outlet 151, and an ink barrel 16 is arranged under the oil outlet 151. An oil suction pipe 171 is arranged in the ink barrel 16, and the end of the oil suction pipe 171 away from the ink barrel 16 is connected with a pneumatic diaphragm pump 17. The pneumatic dia...

Embodiment 2

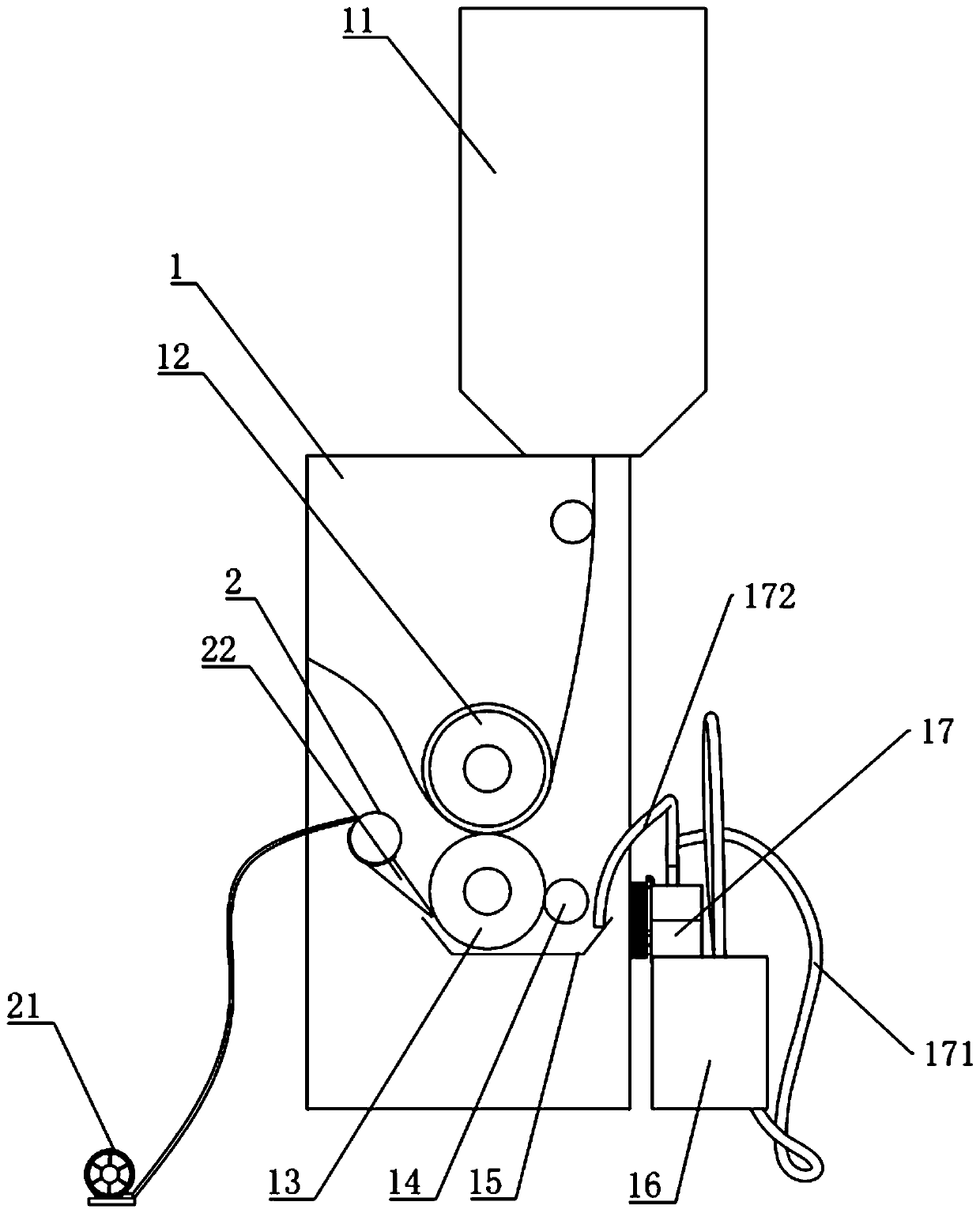

[0050] Embodiment 2, a gravure printing machine scraping device, differs from Embodiment 1 in that, as figure 2 As shown, in the printing process of Embodiment 1, before the ink in the graphic part is printed on the film, the ink on the surface of the entire printing roller 13 needs to be scraped off so that only the graphic part is stored on the entire printing roller 13. The ink is printed onto the film to get the desired pattern. For this reason, one side of the printing roller 13 is provided with the air jet tube 2 connected to the blower 21, the below of the air jet tube 2 is connected with the air flow channel 22 arranged towards the printing roll 13 tangential direction, the cross section of the air flow channel 22 is from the air jet tube 2 One end of the air flow channel 22 gradually becomes smaller to the other end, and the air injection direction of the air flow channel 22 is opposite to the linear velocity direction of the printing roller 13 near the air outlet of...

Embodiment 3

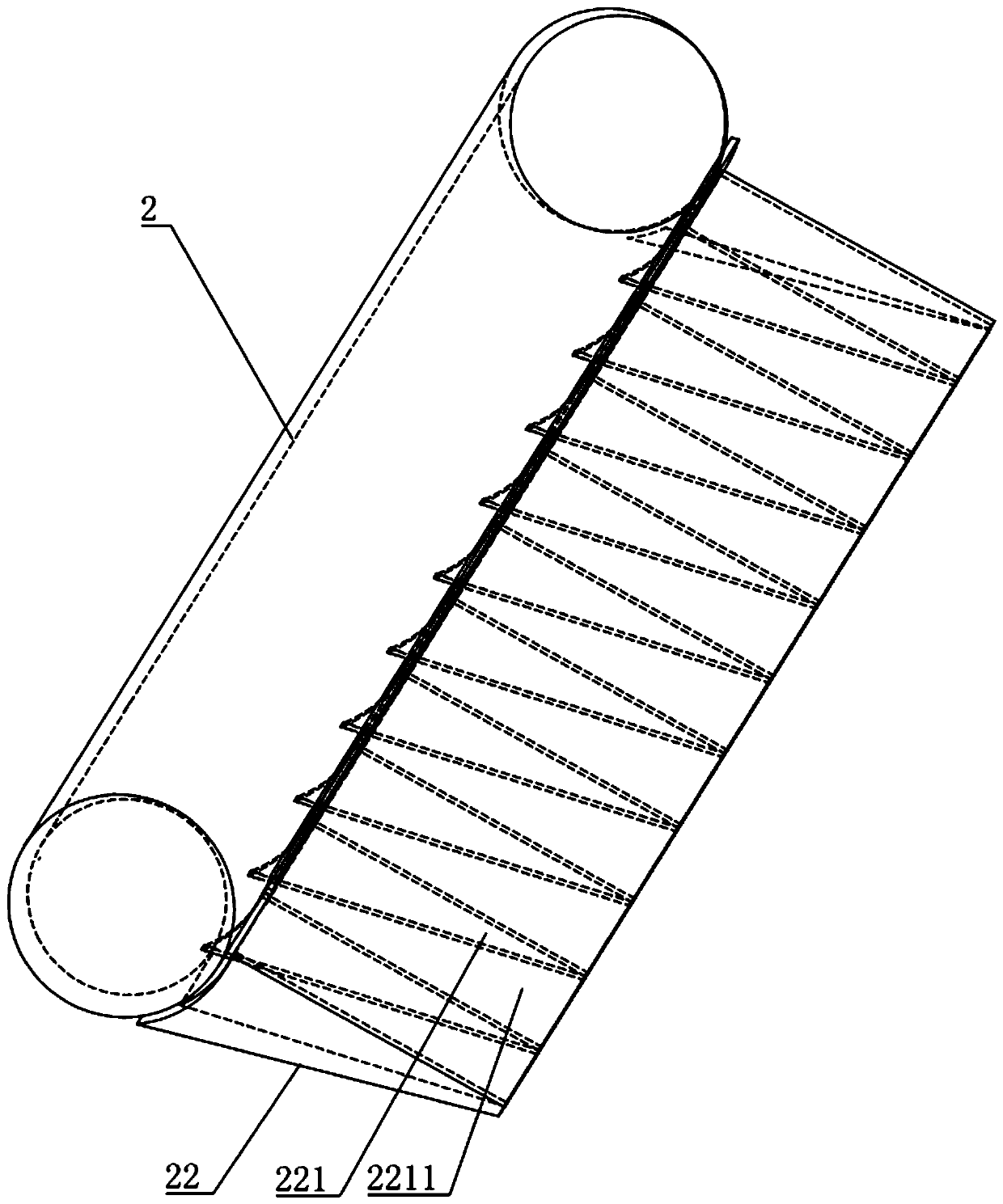

[0053] Embodiment three, a gravure printing machine scraping device, differs from embodiment two in that, as figure 2 , 3 , 4 and 5, several partitions 221 are evenly distributed along the axial direction of the printing roller 13 in the air flow channel 22, and are used to divide the air flow channel 22 into several air chambers 2211. A slot 222 is provided on the side of each air chamber 2211 away from the printing roller 13 , and an arc-shaped insert 23 is arranged in the slot 222 . The arc-shaped insert 23 has the same radius of curvature as the air jet 2 .

[0054] Such as Figure 5 As shown, a pair of hook edges 231 are provided on both sides of the arc-shaped flashboard 23 on the cylinder wall of the jet tube 2 toward the arc-shaped flashboard 23, and a gap for the arc-shaped flashboard 23 to slide is formed between the hook edges 231 and the jet barrel 2. Guide groove 2311.

[0055] Specific instructions:

[0056] The high-pressure air ejected from the air flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com