Plane scraping method based on flatness measurement

A technology of flatness and flatness, which is applied to the parts of grinding machine tools, the control of workpiece feed movement, and grinding machines. It can solve problems such as disturbance deformation, low work efficiency, and high difficulty, and meet the requirements of reducing proficiency. Save the time of scraping and grinding and improve the effect of pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

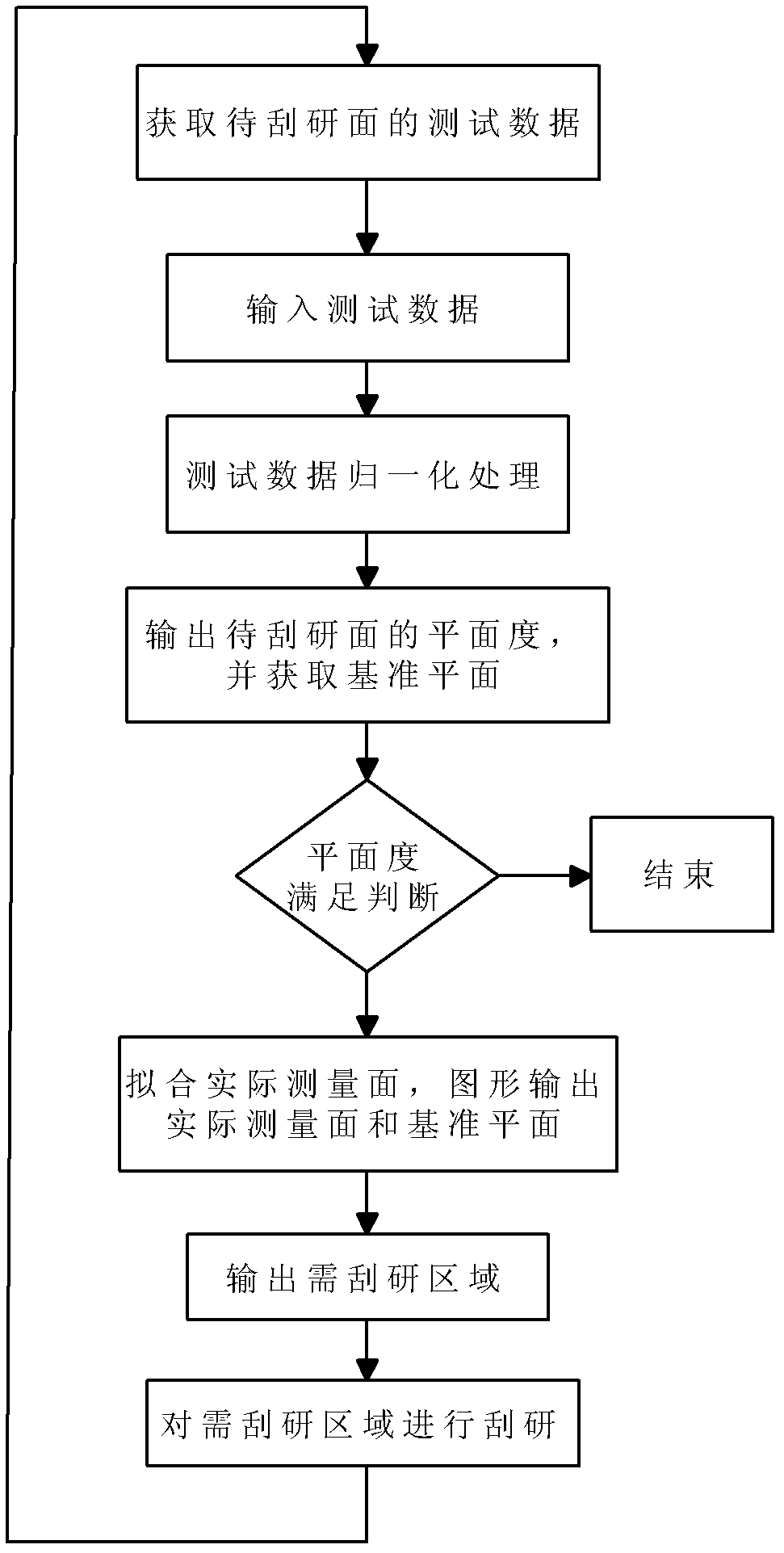

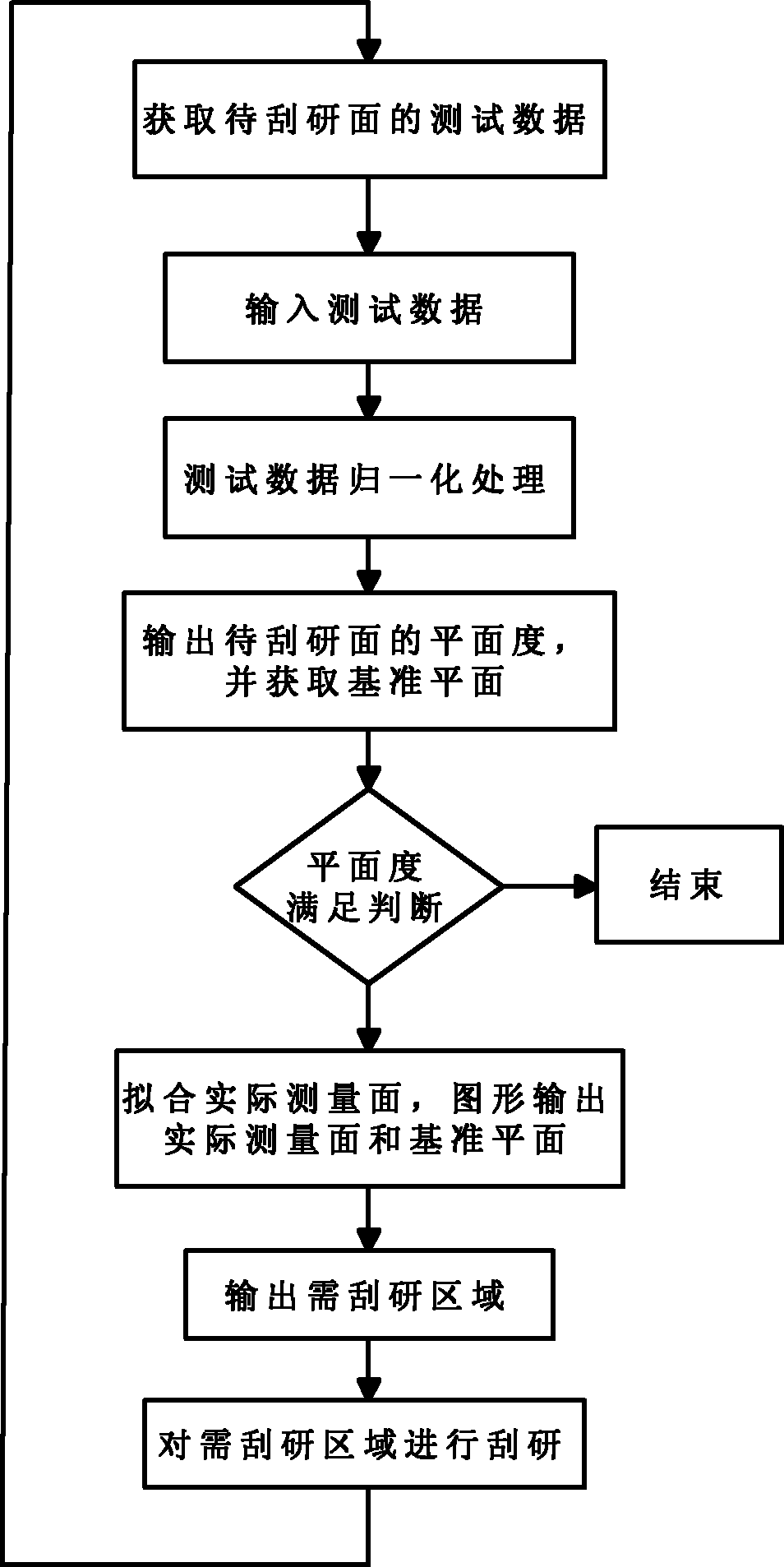

[0024] see Figure 1-2 Shown, a kind of plane scraping grinding method based on flatness measurement, this scraping grinding method comprises the following steps:

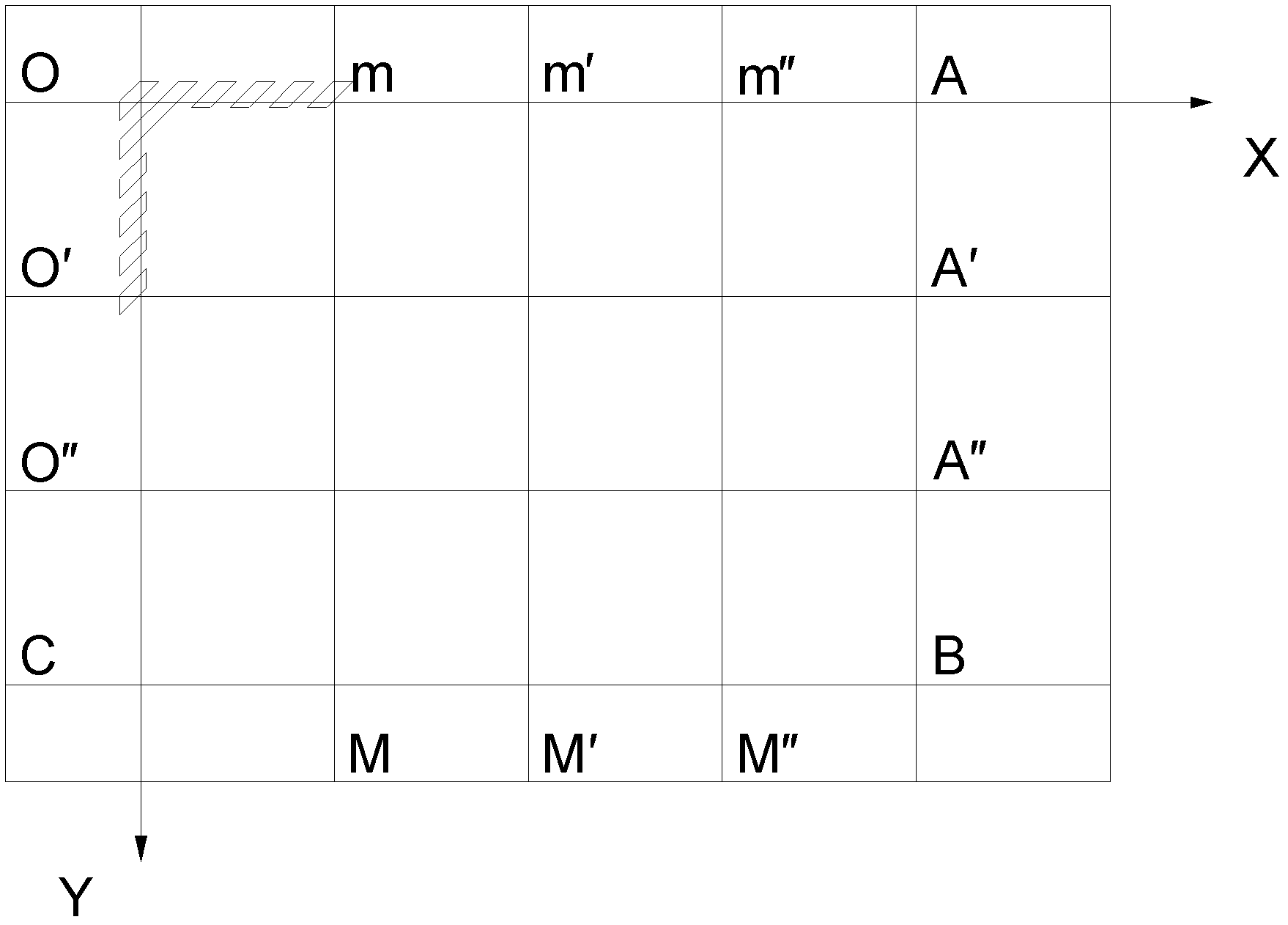

[0025] First, obtain the coordinates of multiple points on the surface to be scraped and grind, and record the abscissa and ordinate of these multiple points in matrix A and matrix B respectively. When obtaining these multiple points, a grid method can be used to obtain them. When the grid method obtains multiple points, such as figure 2 As shown, the reference plane is determined by two straight lines OmX and OO'Y, and the straight lines OX and OY are preferably selected as two lines perpendicular to each other and parallel to the contour edge of the surface to be scraped and ground respectively. When measuring, first measure the outline of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com