Galvanized steel wire galvanizing device

A technology of galvanized steel wire and steel wire, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as intermittent scraping, poisoning of operators, and solidification of surface galvanized solution, so as to reduce solidification Effects that increase speed, increase effects, and reduce the chance of poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

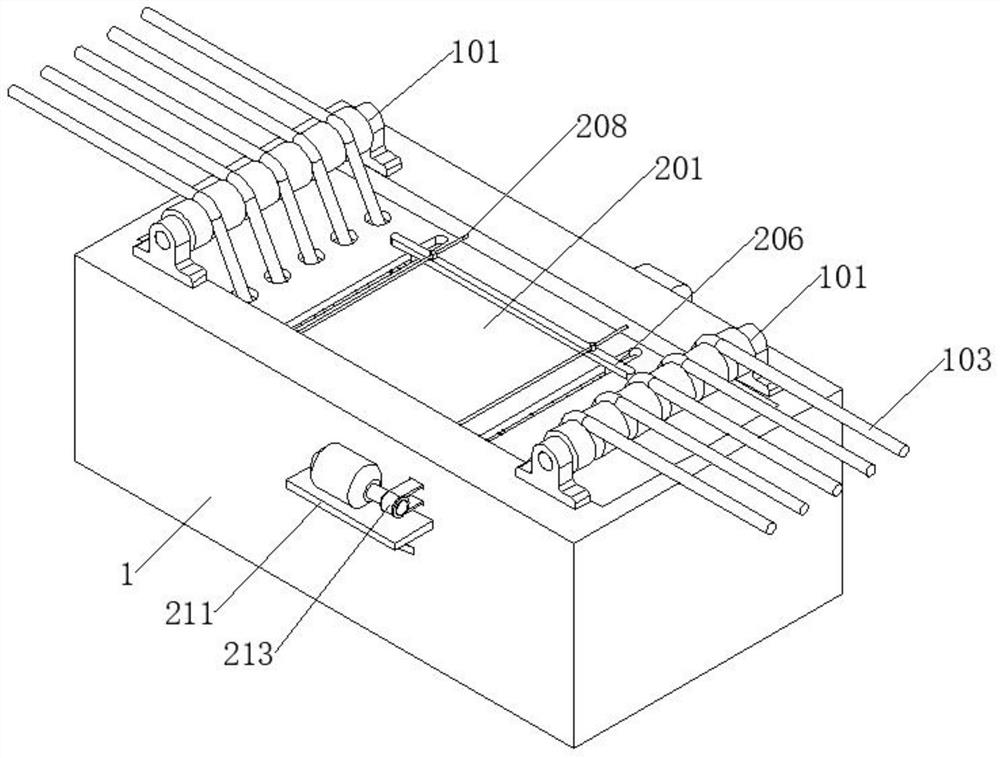

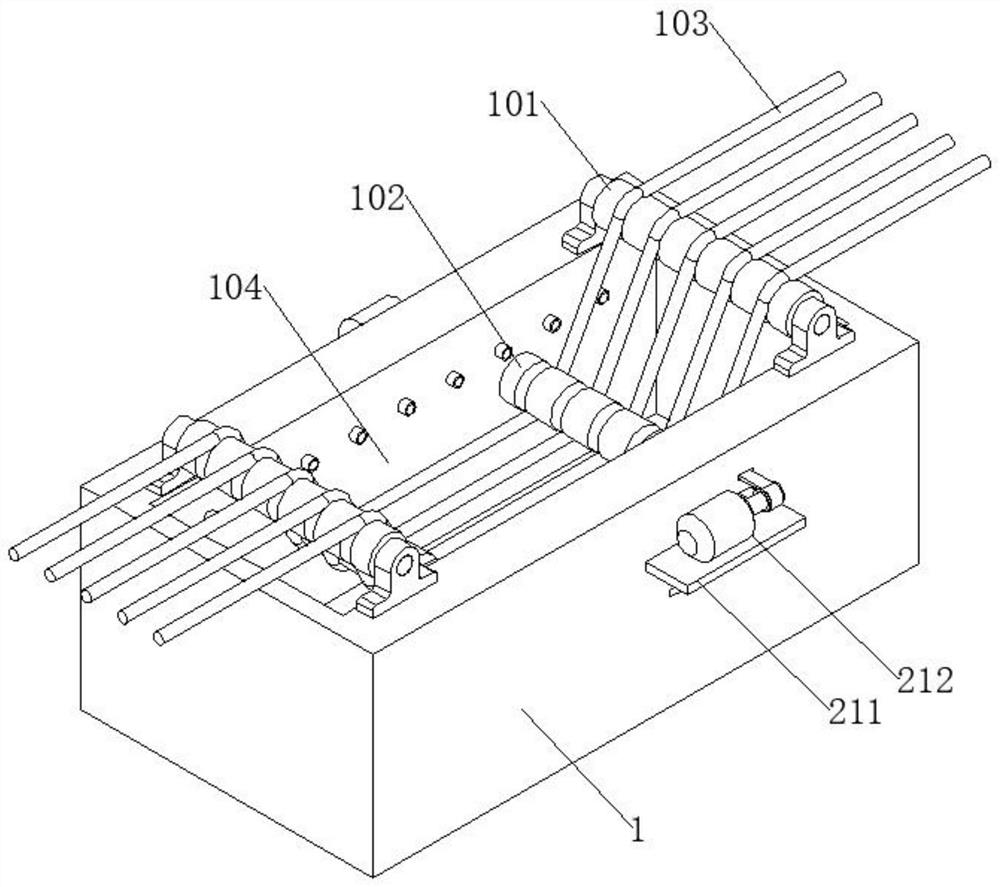

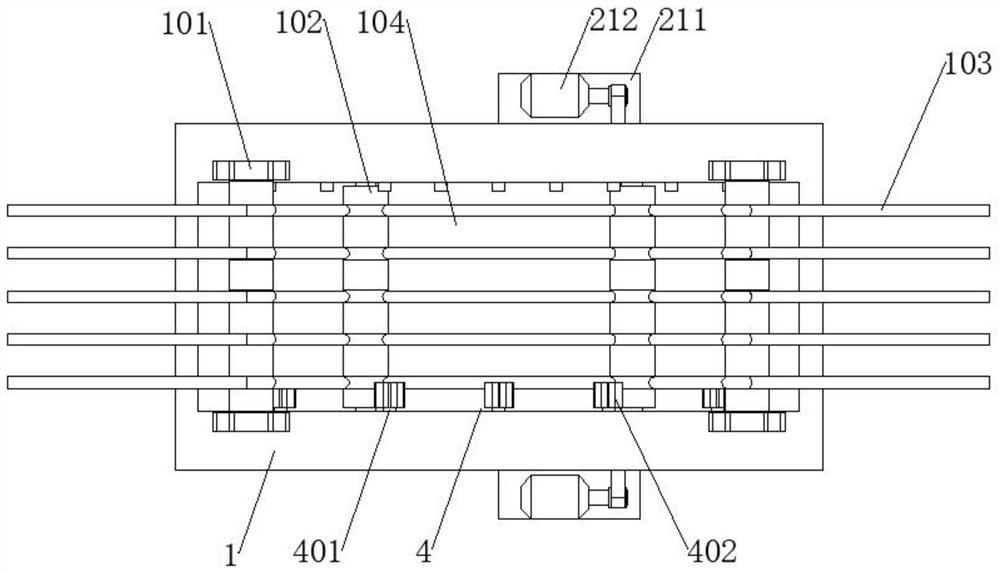

[0032] The invention discloses a galvanized steel wire galvanizing device. Figure 1-Figure 9 As shown, it includes a galvanizing tank 1, a thermal insulation automatic scraping mechanism 2 for scraping off the solidified galvanizing solution, a monitor 3 for monitoring the solidification, a continuous stirring mechanism 4 for stirring the solidified galvanizing solution, and a strong air jet Blow mechanism 5.

[0033] ginseng Figure 1-Figure 4 As shown, a pair of guide rollers 101 are installed on the galvanizing tank 1 to guide the delivery of the steel wire 103. A galvanizing solution tank 104 is excavated in the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com