Extinction spinning production process for polylactic acid slice with titanium dioxide

A titanium dioxide and production process technology, which is applied in the field of polylactic acid chips adding titanium dioxide matte spinning production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

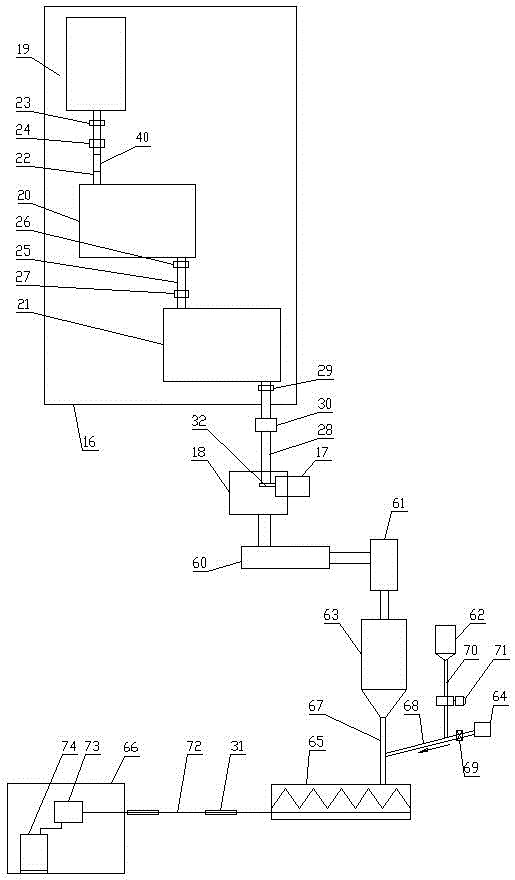

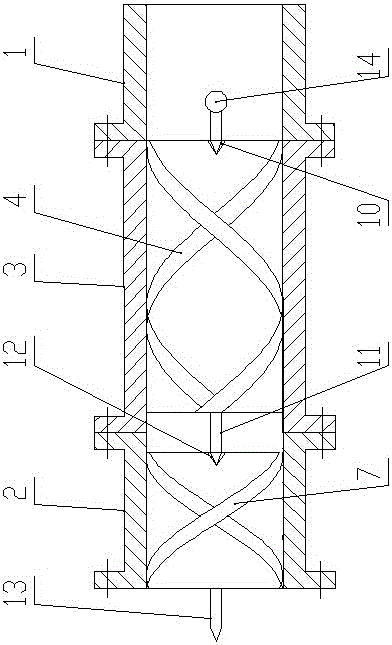

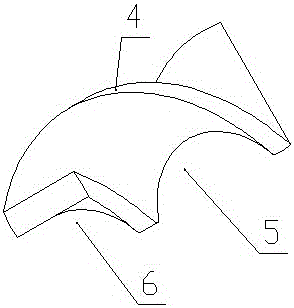

[0043] Such as Figure 1-Figure 6 As shown, the polylactic acid chip adding titanium dioxide matting spinning production equipment of the present invention includes a polymerization frame 16, a pelletizer 17, a cooling pool 18, a vulcanization crystallization bed 60, a drying tower 61, a first silo 62, and a second silo 63. Compressed air system 64, spinning screw extruder 65 and spinning box 66. The polymerization frame 16 is provided with a stirring tank 19, an initial polymerization tank 20 and a final polymerization tank 21 in sequence from top to bottom, and the bottom of the stirring tank 19 The first feed pipe 22 is connected to the top of the initial polymerization tank 20, the first feed pipe 22 is provided with a polylactic acid prepolymerization mixing device 40, the first automatic control valve 23 and the first metering pump 24, the initial polymerization tank 20 The bottom is connected to the top of the final polymerization tank 21 through the second feed pipe 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com