Preparation method for pure cotton non-woven product

A technology for non-woven fabrics and products, applied in the field of preparation of pure cotton non-woven products, can solve the problems of insufficient softness, discomfort, limited application range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

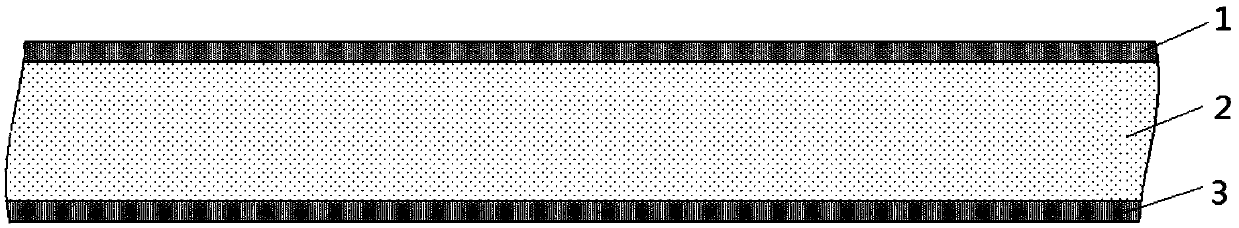

[0027] The preparation method of a kind of pure cotton nonwoven product of the present application, adopts natural cotton fiber as raw material, carries out needle-punching and hydroentangling treatment to natural cotton fiber, wherein carries out needle-punching to whole cotton web, makes its fiber entanglement firmly and Keep fluffy and soft, so that the inner cotton fibers do not move, clumping and voids, and then the surface and bottom layer of the needle-punched cotton web are spunlace on the front and back, so that the surface and bottom layer are strengthened and become the core of non-woven fabrics. state, thus forming an integrated structure of "cloth-mesh-cloth". Compared with the original secondary combination of external adhesion layer and cotton fiber, the integrally formed pure cotton non-woven product is more comfortable, skin-friendly and breathable, and the non-woven fabric structure of the surface layer and the bottom layer binds the cotton wadding of the inne...

Embodiment 1

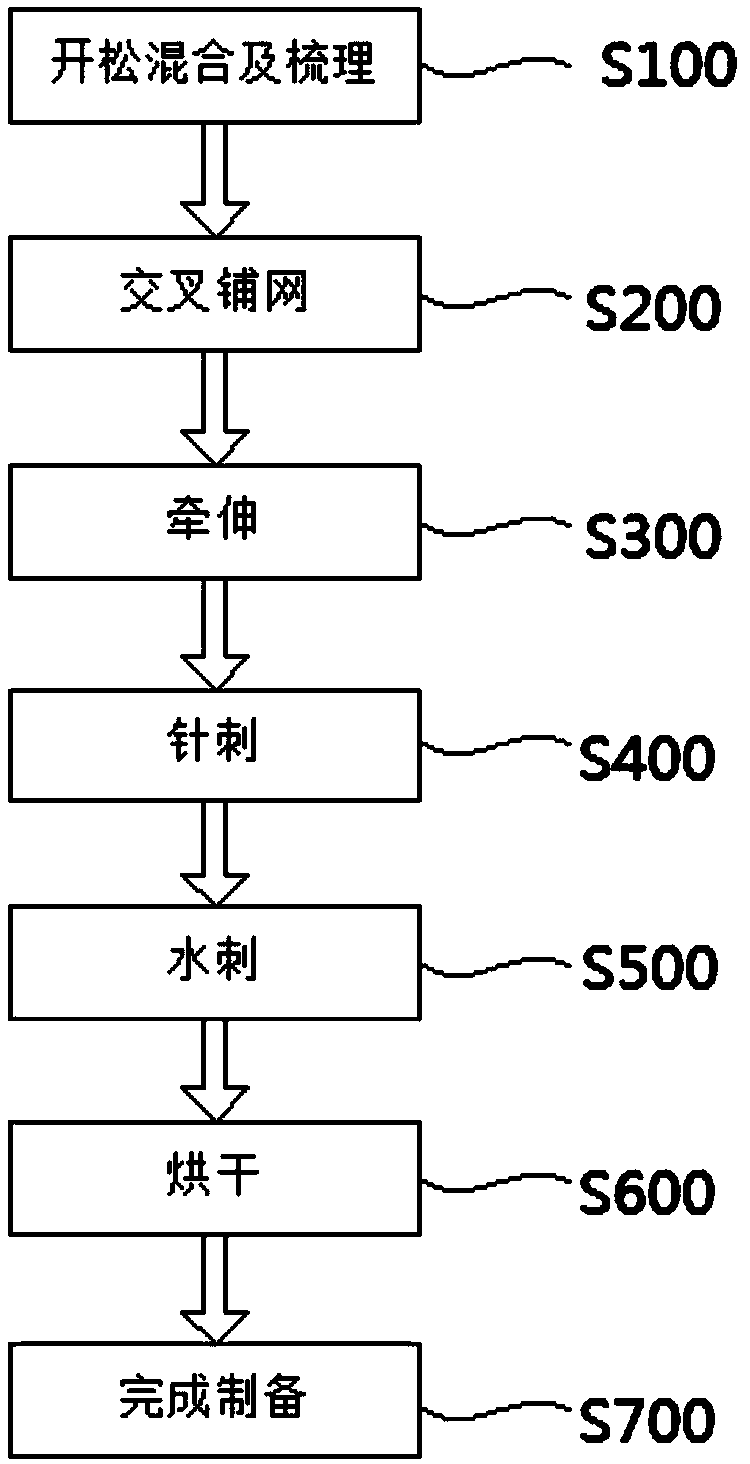

[0030] Such as figure 1 Shown, a kind of preparation method of pure cotton nonwoven product, comprises the following steps:

[0031] S100: Opening, mixing and carding;

[0032] Open the compacted and messy entangled natural cotton fiber raw materials, remove impurities, and mix them evenly. After evenly mixing, comb the cotton fibers to prevent static electricity and accidents.

[0033] S200: cross-lapping;

[0034] The carded cotton fiber is sent to the cross-lapper, and the cross-lapper cross-lays the cotton fiber back and forth to form a cotton web of a certain thickness.

[0035] At present, the technology of direct laying out of the net is mostly used in the process. The cotton net after straight laying out of the net has weak lateral strength, which cannot achieve the purpose of increasing the strength of the fabric. The transverse strength of the cotton web after cross-lapping is greatly improved, and the structural stability of the cotton web is improved to a certai...

Embodiment 2

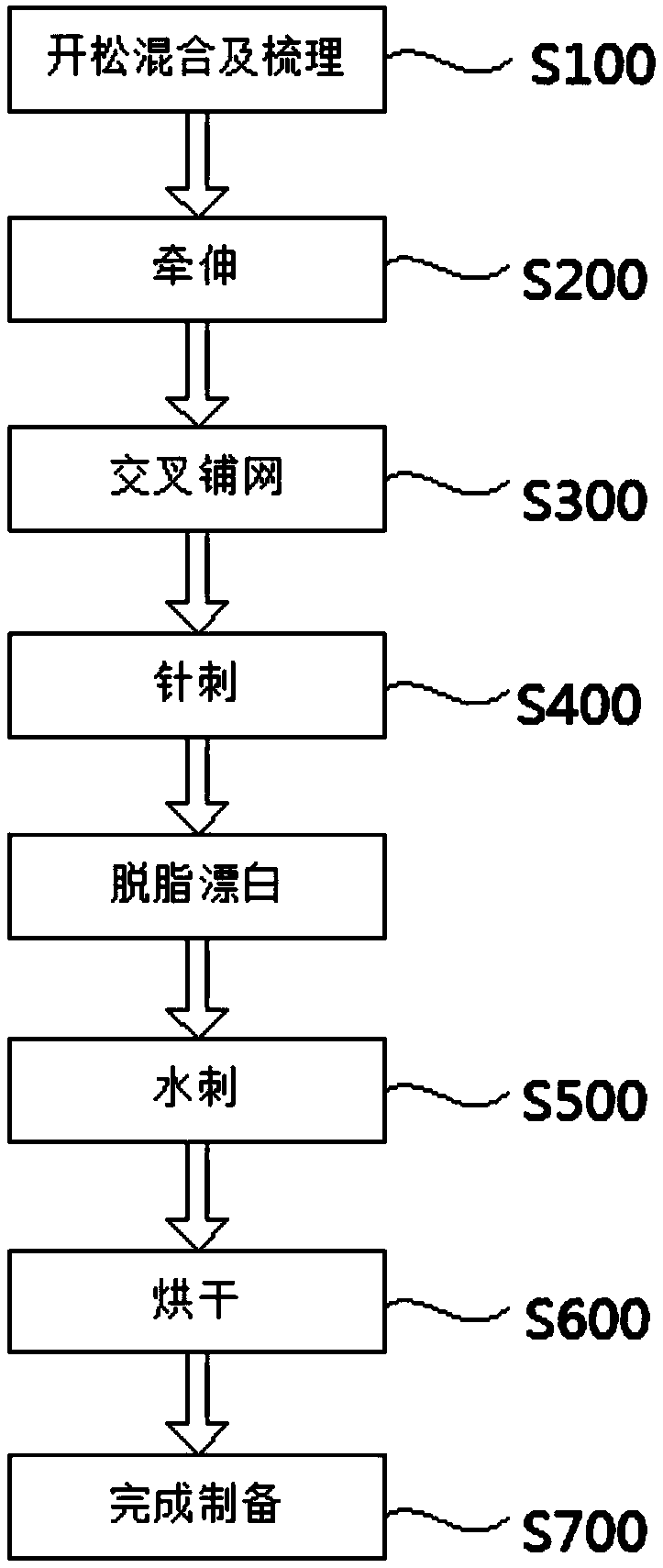

[0058] Such as image 3 As shown, on the basis of Example 1, a degreasing and bleaching step is added after needle punching and before spunlace, and degreasing and bleaching can improve the whiteness and water absorption performance of the product.

[0059] The degreasing step is to remove the cotton wax on the cotton net. The moisture absorption performance of the degreased raw cotton is significantly increased. After many tests in this application, its water absorption capacity can reach 23-24 times its own weight. After the cotton fiber is degreased, it is bleached with hydrogen peroxide, and the whiteness can reach 97 degrees. In other embodiments, other methods of bleaching can also be used.

[0060] After the degreasing and bleaching is completed, the needle-punched cotton web is hydroentangled. In addition to the advantages of the product in Example 1, the final nonwoven product prepared in this embodiment has clearer lines. This is because the needled cotton web is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com