A preparation method of high-purity tantalum target material for electronic materials

A technology for electronic materials and tantalum targets, which is applied in metal material coating technology, metal processing equipment, ion implantation plating, etc. Low rate and other problems, to achieve the effect of easy guarantee of product purity, lower preparation process temperature, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

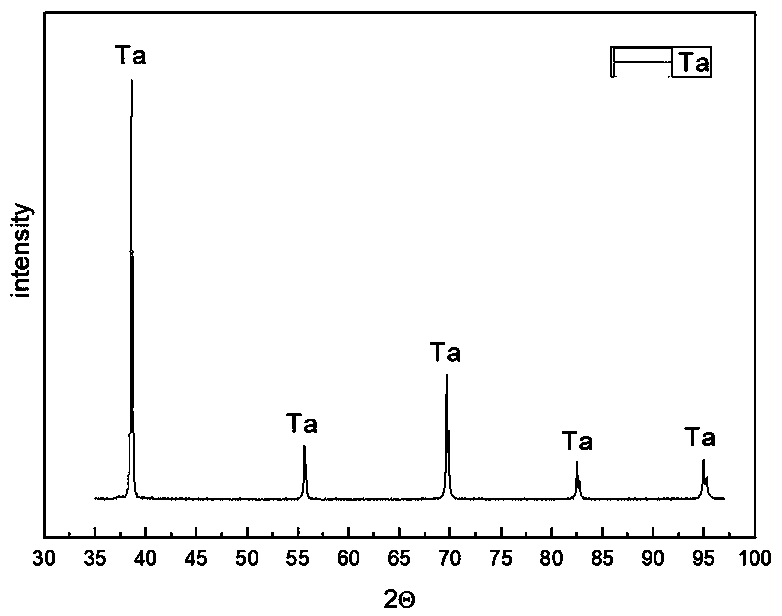

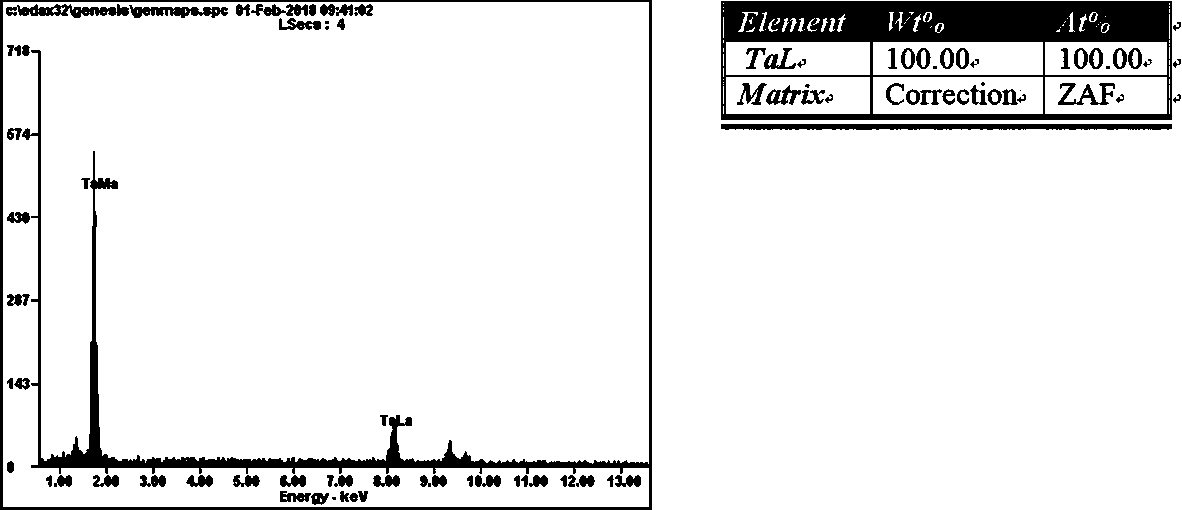

[0033] A method for preparing a tantalum target for electronic materials, comprising the steps of:

[0034] (1) Crushing: the industrially purified high-purity tantalum block with a purity >99.95% is broken into a powder with a particle size of <2mm by a crusher, and then sieved to obtain a fine powder;

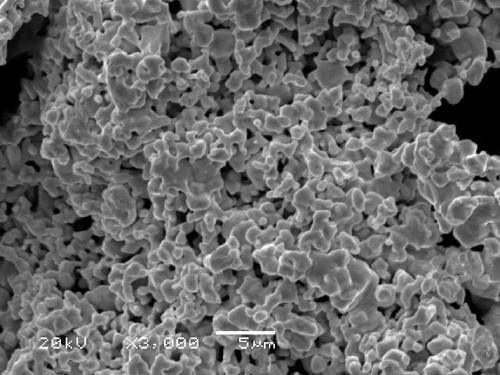

[0035] (2) Ball milling: fill the ball mill cylinder with nitrogen, and under the protection of nitrogen, the fine powder obtained in step (1) is ball milled by ball milling balls until the particle size is 5-150 μm, and the volume average particle size is 55-65 μm. Get tantalum powder;

[0036] (3) Molding: Take three kinds of tantalum powders with different particle sizes and mix them according to a certain ratio. The particle sizes of the three kinds of powders are D 1 、D 2 and D 3 , where D 1 =5-20μm, D 2 =45-75μm, D 3 =80-150μm; the particle size is D 1 、D 2 and D 3 The mass ratio of the three powders is 3-4:2-4:1-2; mix the above three powders evenly to obtain ...

Embodiment 1

[0050] The industrially purified high-purity tantalum block with a purity >99.95% is broken into small particles <2mm by a crusher, and ball milled under a protective atmosphere. The diameters of the balls are: 3mm, 7mm, and 10mm. The ratio is 10:5:2, the ratio of the total mass of the balls to the mass of the material is 2:1, and the ball mills until the particle size is in the range of 5-150 μm, and the volume average particle size is 55 μm. Take three kinds of powders with a particle size of 5 μm, 75 μm and 150 μm, mix them evenly according to the mass ratio of 4:3:2, put them into a high-strength graphite mold after drying, and use a gasket to separate the tantalum powder and the punch. Prevent sticking before placing in upper and lower die punches. Then vibrate and compact the powder into the lower pressure head of the high-temperature hot-press furnace, and adjust the position to ensure that the mold is located in the center of the lower pressure head to ensure that the ...

Embodiment 2

[0053] The industrially purified high-purity tantalum block with a purity >99.95% is broken into small particles of 3 ; The surface of the high-purity tantalum blank is ground and polished, and the size is processed according to the magnetron sputtering equipment to obtain a high-purity tantalum target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com