Sectional pin for semiconductor coating equipment

A coating equipment and segmented technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high processing cost, difficult installation, complex structure, etc., and meet the requirements of low price, simple structure, and precision not high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

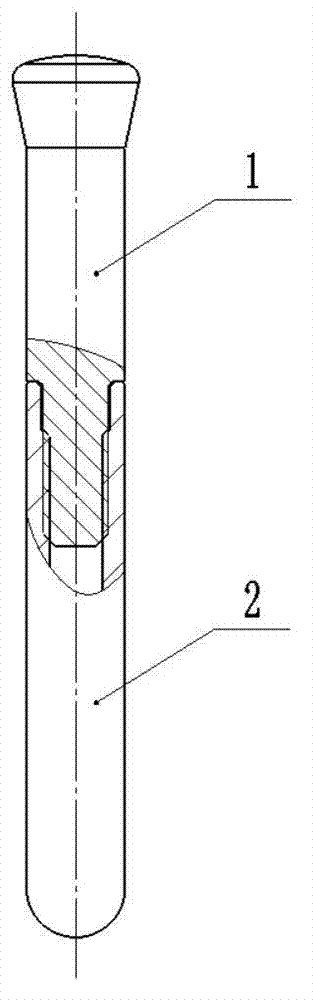

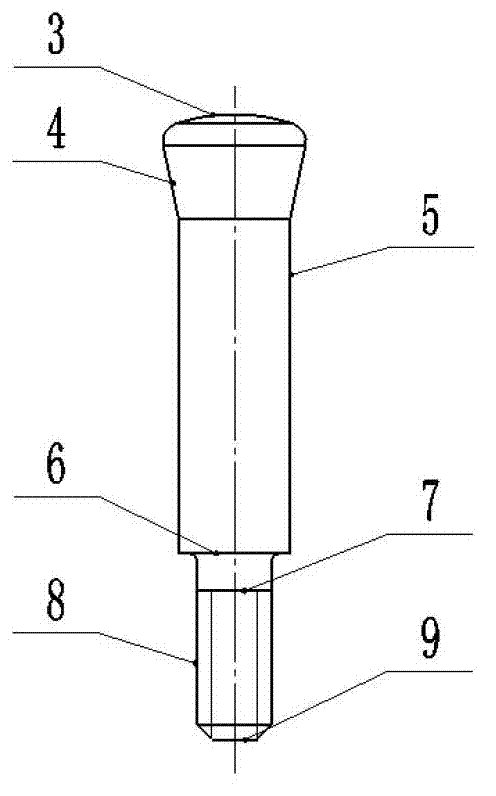

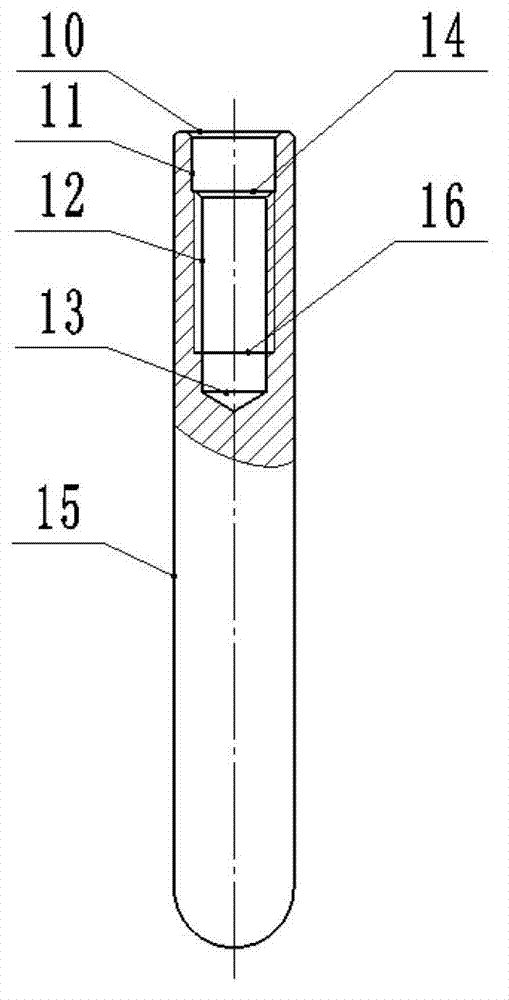

[0012] refer to Figure 1-3 , a segmented pin for semiconductor coating equipment, the segmented pin is composed of an upper part 1 and a lower part 2 of the pin. The upper part 1 of the pin and the lower part 2 of the pin are connected by an external thread 8 and an internal thread 12 respectively. The upper end of the upper part 1 of the pin adopts a conical surface 4, and the top end is shaped on a spherical surface 3.

[0013] After the upper part 1 of the pin is connected with the lower part 2 of the pin, in order to ensure the overall performance of the entire pin, the outer surface A5 and the outer surface B15 of the two need to reach a certain straightness. In order to ensure the straightness between the two parts, it is required that the final contact surface A6 and contact surface B10 of the pin upper part 1 and the pin lower part 2 maintain a certain degree of perpendicularity with their outer surface A5 and outer surface B15 respectively, and be in coincidence aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com