Diatomite and kaolin thermal-insulation film master batch and preparation method thereof

A technology of diatomite and kaolin, applied in the field of composite material master batch and its preparation, can solve the problems of high cost, complicated process, complicated master batch production process, etc., and achieve the effects of improving thermal insulation and anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

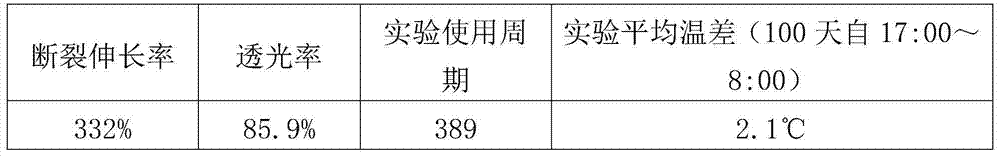

Embodiment 1

[0026] Prepare the following raw materials according to mass percentage, diatomite 22%, kaolin 33%, polyethylene 35%, aluminate coupling agent 3%, stearic acid 0.8%, calcium stearate 0.5%, paraffin wax 3%, PE wax 2%, antioxidant 0.7%. Among them: self-produced diatomite, SiO2 content of 85%, bulk density of 0.45g / ml, specific surface area of 25m 2 / g, the particle size is 1250 mesh; the kaolin is self-produced, the whiteness is 91, SiO 2 The content is 45%, Al 2 o 3 The content is 35%, the water content is 0.1%, and the particle size is 1250 mesh; the grade of polyethylene is DNDA8320, produced by Fushun Petrochemical Company; the grade of aluminate coupling agent is DL-411-A, manufactured by Nanjing Pinning Coupling Agent Co., Ltd.; the grade of stearic acid is 1801, produced by Wujiang Xinchang Fine Chemical Co., Ltd.; the model of calcium stearate is C50, produced by Shijiazhuang Desu Auxiliary Co., Ltd.; the grade of paraffin wax is 58#, produced by Fushun Petrochemic...

Embodiment 2

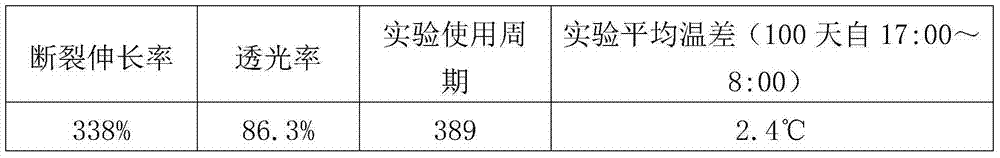

[0037] Prepare the following raw materials according to mass percentage, diatomite 23%, kaolin 33%, polyethylene 34%, aluminate coupling agent 3%, stearic acid 0.8%, calcium stearate 0.4%, paraffin wax 3%, PE wax 2%, antioxidant 0.8%. Among them: self-produced diatomite, SiO2 content of 86%, bulk density of 0.5g / ml, specific surface area of 30m 2 / g, the particle size is 1300 mesh; the kaolin is self-produced, the whiteness is 92, SiO 2 The content is 46%, Al 2 o 3 The content is 36%, the water content is 0.1%, and the particle size is 1300 mesh; the grade of polyethylene is DNDA8320, produced by Fushun Petrochemical Company. Other components and mixing, extrusion and mechanical property testing methods are the same as in Example 1.

[0038] The masterbatch is approximately cylindrical particles with a length of 10mm, and there are about 500 particles per 10g of masterbatch.

[0039] Table 3 is the technical index of diatomite and kaolin film insulation masterbatch of t...

Embodiment 3

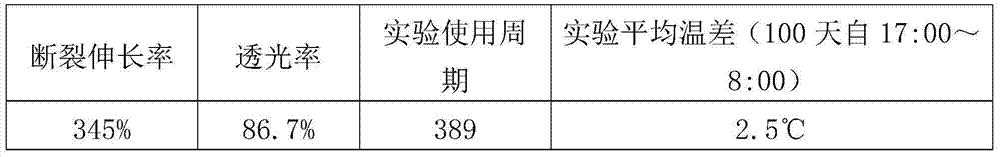

[0046] Prepare the following raw materials according to mass percentage, diatomite 24%, kaolin 33%, polyethylene 34%, aluminate coupling agent 3%, stearic acid 0.5%, calcium stearate 0.5%, paraffin 3%, PE wax 1.5%, antioxidant 0.5%. Among them: self-produced diatomite, SiO2 content is 86%, bulk density is 0.55g / ml, specific surface area is 35m 2 / g, the particle size is 1400 mesh; the kaolin is self-produced, the whiteness is 92, SiO 2 The content is 47%, Al 2 o 3 The content is 36%, the water content is 0.1%, and the particle size is 1400 mesh; the grade of polyethylene is 0474, which is produced by Qatar Petrochemical Company. Other components and mixing, extrusion and mechanical property testing methods are the same as in Example 1.

[0047] The masterbatch is approximately cylindrical particles with a length of 6mm, and there are about 550 particles per 10g of masterbatch.

[0048] Table 5 is the technical index of the diatomite and kaolin film insulation masterbatch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com