Manufacturing method for large tantalum plate

A large-size, plate technology, applied in the field of preparation of large-size tantalum plates, can solve the problems such as the inability to continuously and stably produce large-size tantalum plates, and achieve the effects of excellent mechanical properties, good surface quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

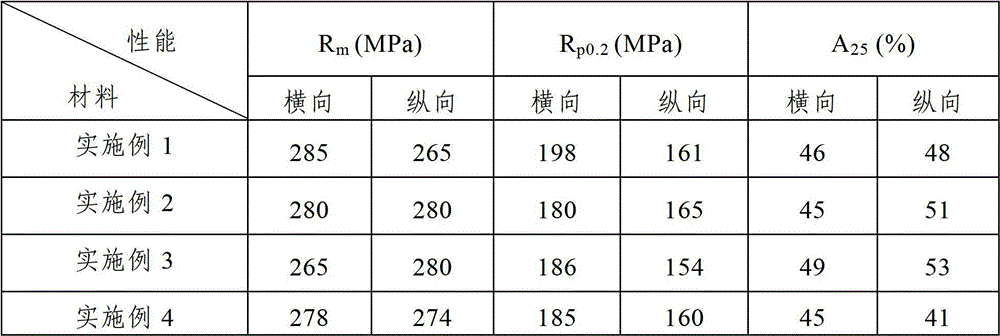

Examples

Embodiment 1

[0023] The preparation method of the large-size tantalum plate of the present embodiment comprises the following steps:

[0024] Step 1. Heat the pure tantalum slab with a thickness of 50mm, a width of 220mm and a length of 248mm to 500°C, and then send the heated tantalum slab into a rolling mill for rolling. The rolling process is as follows: first heat The final tantalum slab is sent into the rolling mill along the length direction for 2-pass rolling until the length is 420mm, and the pass processing rates are 26% and 20.2% respectively, and then the rolled tantalum slab is rotated 90° before rolling. 10-pass rolling, the pass processing rate is 20%, 20%, 19%, 18%, 17%, 16%, 15%, 13.2%, 12%, 12%, resulting in a thickness of 5mm and a width of 420mm , a rolled slab with a length of 1300mm; the total processing rate of the rolling is 90%;

[0025] Step 2, using a leaf wheel to carry out surface grinding treatment on the rolled slab described in step 1;

[0026] Step 3, plac...

Embodiment 2

[0031] The preparation method of the large-size tantalum plate of the present embodiment comprises the following steps:

[0032] Step 1. Heat a pure tantalum slab with a thickness of 40mm, a width of 250mm, and a length of 360mm to 480°C, and then send the heated tantalum slab into a rolling mill for rolling. The rolling process is as follows: first heat The final tantalum slab is sent into the rolling mill along the length direction for 2-pass rolling until the length is 500mm, and the pass processing rate is 18% and 12.2% respectively, and then the rolled tantalum slab is rotated 90° before rolling. 7-pass rolling, the pass processing rates are 30%, 28%, 19%, 18%, 17%, 15%, 12%, respectively, to obtain a rolled slab with a thickness of 6mm, a width of 500mm, and a length of 1200mm ; The total processing rate of the rolling is 85%;

[0033] Step 2, using a leaf wheel to carry out surface grinding treatment on the rolled slab described in step 1;

[0034] Step 3, place the r...

Embodiment 3

[0039] The preparation method of the large-size tantalum plate of the present embodiment comprises the following steps:

[0040]Step 1. Heat the pure tantalum slab with a thickness of 45mm, a width of 163.8mm and a length of 200mm to 450°C, and then send the heated tantalum slab into a rolling mill for rolling. The rolling process is as follows: first The heated tantalum slab is sent into the rolling mill along the length direction and rolled for 5 passes until the length is 504mm. The tantalum slab was rotated 90° and then rolled for 9 passes. The pass processing rates were 30%, 27%, 27%, 21%, 20%, 18%, 15.8%, 12%, and 12%. A rolled slab with a thickness of 2.25mm, a width of 504mm, and a length of 1300mm; the total processing rate of the rolling is 95%;

[0041] Step 2, using a leaf wheel to carry out surface grinding treatment on the rolled slab described in step 1;

[0042] Step 3, place the rolled slab after the surface grinding treatment in step 2 in a vacuum annealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com