Technology for making metallic pipe with nano-structure metal wire screen-ceramic liner

A technology of wire mesh and nanostructure, which is applied in pipeline protection, mechanical equipment, pipes/pipe joints/fittings, etc., which can solve the difficulties of transportation, production, use and maintenance, the complex factors affecting the preparation process, and the inability of special-shaped pipes to be integrated as a whole, etc. problems, to achieve the effect of high hardness, strong controllability of process parameters, and high performance-price ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

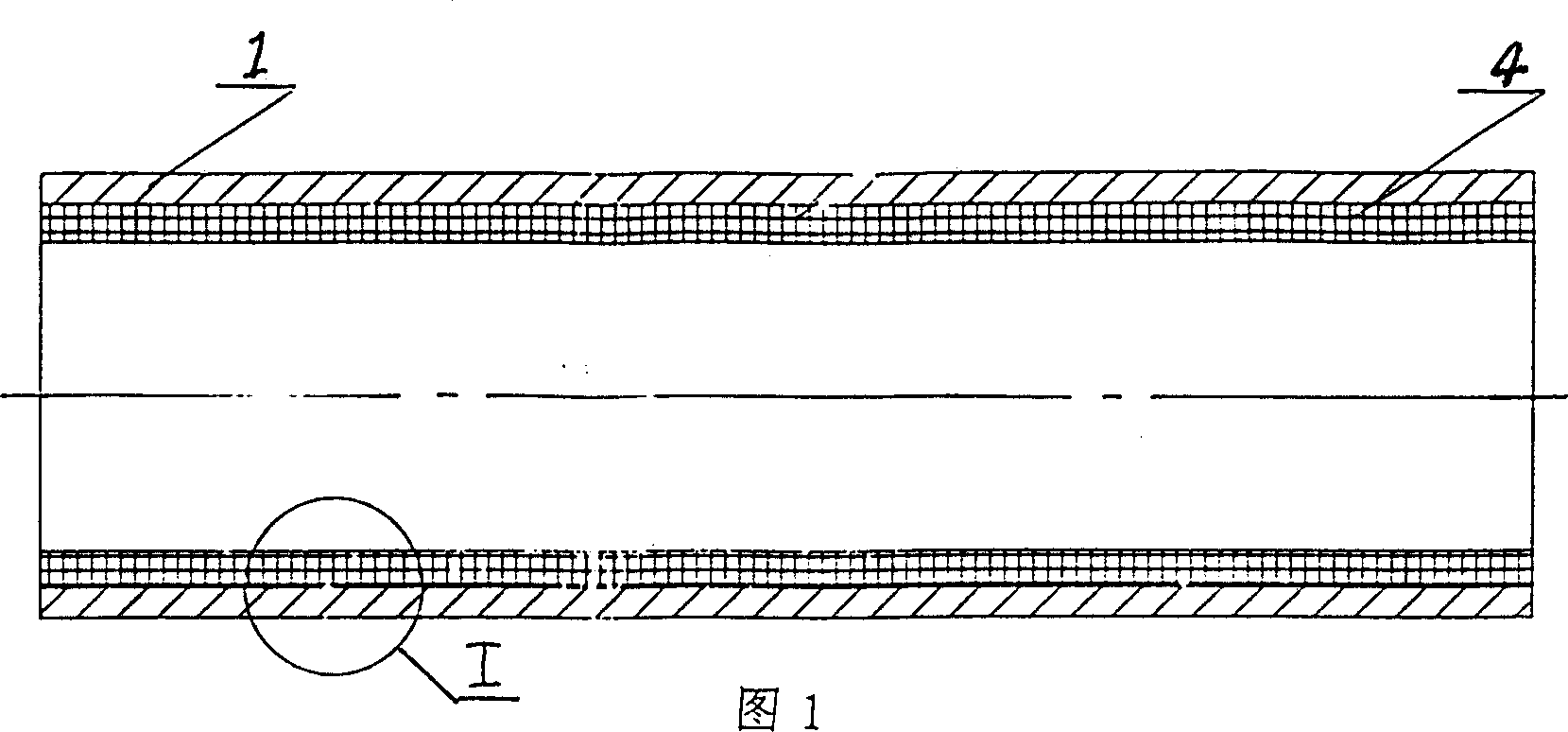

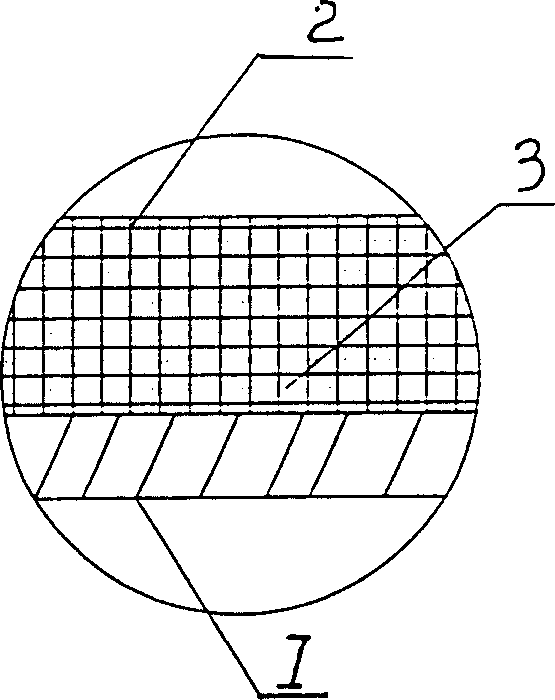

[0078] The nanostructure wire mesh-ceramic composite lined metal straight pipe with uniform and equal wall thickness and its preparation process are shown in Figure 1 and figure 2 . This embodiment is composed of a seamless steel straight pipe 1 and a liner pipe 4 with uniform and equal wall thickness composed of a low-carbon steel nano-structured wire mesh 2 and a ceramic wear-resistant material 3 . The nano-structure wire mesh 2 and the ceramic wear-resistant material 3 are combined into one body, and serve as the inner liner 4 of the seamless steel straight pipe 1 . The lining pipe 4 is closely attached to the seamless steel straight pipe 1 . The nanostructure wire mesh 2 in this embodiment is made of wires with a diameter of 0.5mm low carbon alloy steel nanostructures, but it can also be made with high and medium carbon steel nanostructures wires. It can be either single-layer weaving or multi-layer high-density weaving. The ceramic wear-resistant material 3 of this emb...

Embodiment 2

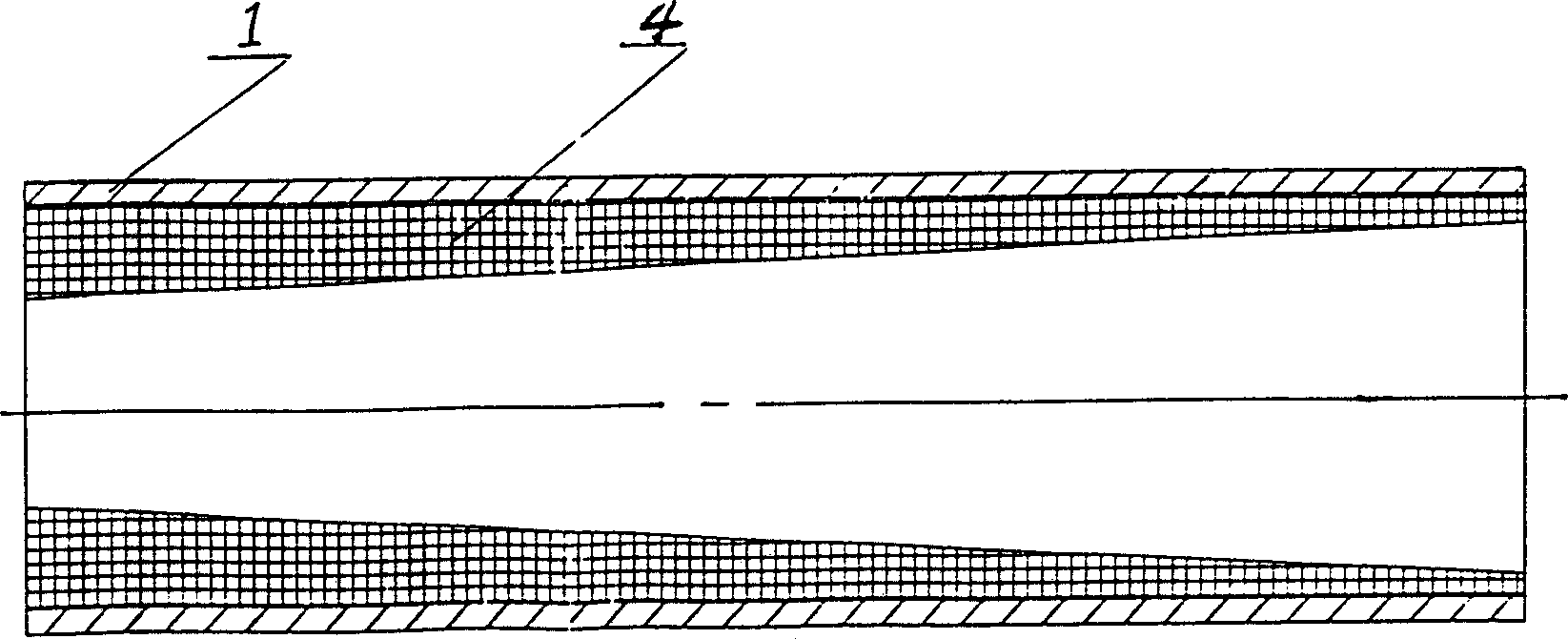

[0089] Nano-structured wire mesh-ceramic composite lined metal pipe with inner cone and outer straight and its preparation process

[0090] see image 3 and figure 2 . This embodiment is composed of a seamless steel straight pipe 1 and a tapered inner pipe 4 with unequal wall thickness composed of a medium-carbon alloy steel nano-structured wire mesh 2 and a ceramic wear-resistant material 3 . The nano-structure wire mesh 2 and the ceramic wear-resistant material 3 are combined into one body, and serve as the inner liner 4 of the seamless steel straight pipe 1 . The lining pipe 4 is closely attached to the seamless steel straight pipe 1 . The nanostructured metal wire mesh 2 in this embodiment is made of carbon alloy steel nanostructured wires with a diameter of 1.0 mm. It can be either single-layer weaving or multi-layer high-density weaving. The ceramic wear-resistant material 3 of this embodiment is mainly prepared by corundum ceramic particles (alumina), nylon resin g...

Embodiment 3

[0093] Eccentric Composite Nanostructure Wire Mesh-Ceramic Composite Lined Rubber (Plastic) Straight Pipe and Its Preparation Process

[0094] See Figure 4, Figure 5 and figure 2 . This embodiment is composed of a rubber (plastic) straight pipe 1 and an eccentric liner pipe 4 composed of a wire mesh 2 with a nanostructure of high-carbon alloy steel and a ceramic wear-resistant material 3 . The nano-structure wire mesh 2 and the wear-resistant ceramic material 3 are combined as a whole, and are used as the inner liner 4 of the rubber (plastic) straight pipe 1 . The lining pipe 4 is closely attached to the rubber (plastic) straight pipe 1. The nanostructured wire mesh 2 in this embodiment is made of high carbon alloy steel nanostructured wires with a diameter of 0.01 mm. It can be either single-layer weaving or multi-layer high-density weaving. The ceramic wear-resistant material 3 of this embodiment is mainly prepared by silicon carbide ceramic particles, polyurethane glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com