Method for preparing In2S3 film by chemical bath deposition

A chemical water bath and film deposition technology, which is applied in the field of chemical water bath deposition to prepare In2S3 thin films, can solve the problems of environmental damage, achieve stable chemical composition, strong variability in substrate area and shape, and strong controllability of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

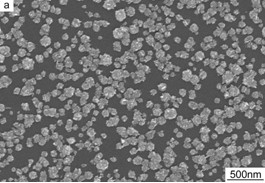

[0028] A glass slide with an area of 76mm×25mm×1mm was used as the coating substrate. The substrate was first soaked in chromic acid washing solution for 30 minutes, then rinsed with deionized water for 5 times, then cleaned with ultrasonic vibration in acetone and ethanol for 5 minutes, and finally rinsed thoroughly with deionized water and then dried at 120°C for 0.5 hours. use.

[0029] Deionized water was used to prepare an aqueous solution, and the components were 0.1 mol / L of indium chloride and 1 mol / L of thioacetamide, and the pH was adjusted to 2.4 by adding acetic acid. After the solution was prepared at room temperature, the coating substrate was placed vertically in the prepared solution, and then the container containing the solution was placed in a constant temperature water bath with a temperature of 70°C, and it was deposited for 0.5h before taking it out. For the freshly deposited film, soak in deionized water for 15 minutes to remove surface residues and t...

Embodiment 2

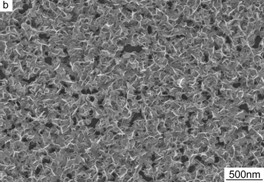

[0032] A glass slide with an area of 76mm×25mm×1mm was used as the coating substrate. The substrate was first soaked in chromic acid washing solution for 30 minutes, then rinsed with deionized water for 5 times, then cleaned with ultrasonic vibration in acetone and ethanol for 10 minutes, and finally rinsed thoroughly with deionized water and then dried at 120 ° C for 1.0 h. use.

[0033] Deionized water was used to prepare an aqueous solution, and the components were 0.1 mol / L of indium chloride and 1 mol / L of thioacetamide, and the pH was adjusted to 2.4 by adding acetic acid. After the solution was prepared at room temperature, the coating substrate was placed vertically in the prepared solution, and then the container containing the solution was placed in a constant temperature water bath with a temperature of 70°C, and taken out after deposition for 1.0 h. For the freshly deposited film, soak in deionized water for 15 minutes to remove surface residues and then dry in ...

Embodiment 3

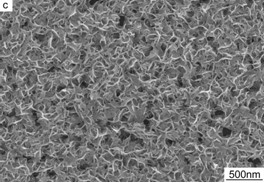

[0036] A glass slide with an area of 76mm×25mm×1mm was used as the coating substrate. The substrate was first soaked in chromic acid washing solution for 30 minutes, then rinsed with deionized water for 5 times, then cleaned with ultrasonic vibration in acetone and ethanol for 15 minutes, and finally rinsed thoroughly with deionized water and then dried at 120°C for 1.5 hours. use.

[0037] Deionized water was used to prepare an aqueous solution, and the components were 0.1 mol / L of indium chloride and 1 mol / L of thioacetamide, and the pH was adjusted to 2.4 by adding acetic acid. After the solution was prepared at room temperature, the coating substrate was placed vertically in the prepared solution, and then the container containing the solution was placed in a constant temperature water bath with a temperature of 70°C, and was taken out after deposition for 1.5 hours. For the freshly deposited film, soak in deionized water for 15 minutes to remove surface residues and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com