A kind of transparent conductive WC film and its room temperature growth method

A transparent conductive, thin-film technology, applied to conductive layers, circuits, electrical components and other directions on insulating carriers, can solve the problem of few WC studies, and achieve the effects of good transparency and conductivity, low deposition temperature, and high deposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

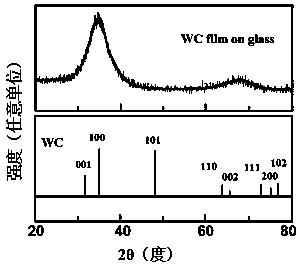

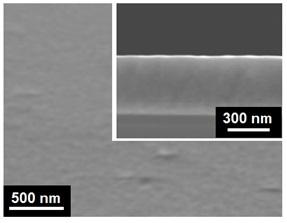

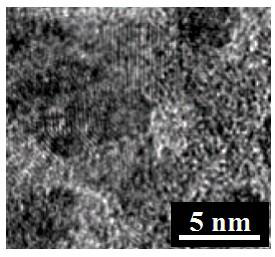

[0023] The invention provides a preparation method of a transparent conductive WC film: adopting the radio frequency magnetron sputtering method, using high-purity WC alloy as the target material, Ar-CH 4 It is the working gas; glass, quartz, PET or Si are respectively used as substrates, which are bombarded by Ar plasma before use; when the reaction chamber is evacuated to a background vacuum higher than 1×10 –4 After Pa, pass into Ar-CH 4 Mixed gas, the gas pressure is kept at 1.0 Pa during the deposition process, CH in the mixed gas 4 The content (in terms of pressure) is 6%; during the deposition process, a mercury lamp is used to irradiate the substrate, and the two main light-emitting wavelengths of the mercury lamp are 185 nm (about 10%) and 254 nm (about 90%); the target The spin rate was 30 rpm and the substrate spin rate was 40 rpm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com