A kind of preparation method of zirconium alloy hot-rolled plate

A zirconium alloy and sheet technology, applied in metal rolling, metal processing equipment, heating/cooling equipment, etc., can solve problems such as restricting the development of zirconium alloy medium and thick sheets, and achieve controllable transfer time, excellent corrosion resistance, and technology. The effect of strong parameter controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

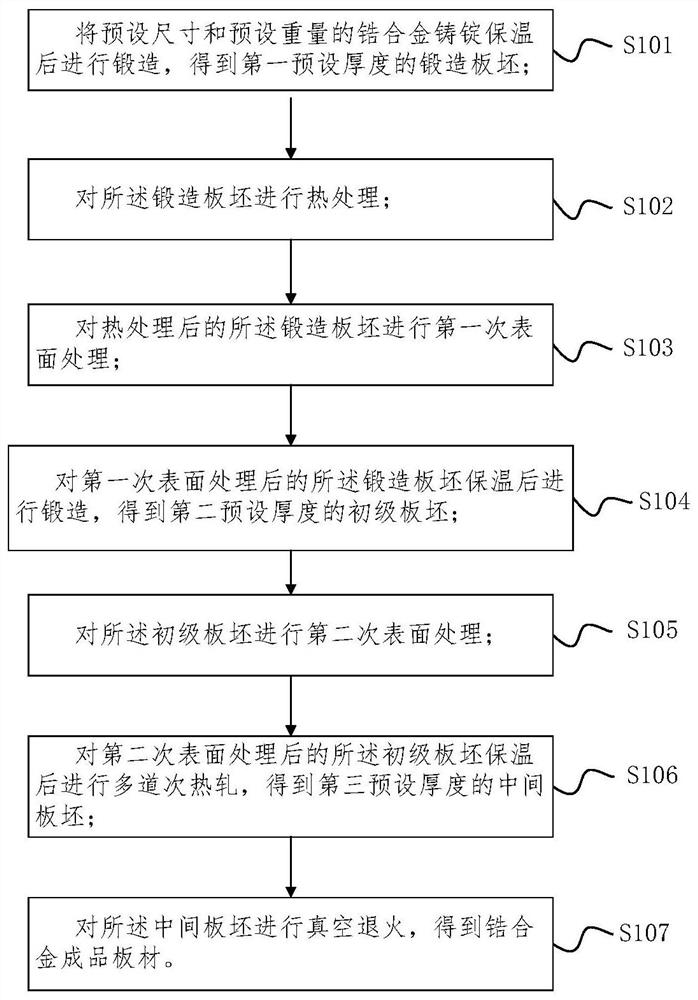

[0039] figure 1 It is a schematic flowchart of a method for preparing a zirconium alloy hot-rolled plate according to a specific embodiment of the present invention. Such as figure 1 Shown, this preparation method flow process comprises:

[0040] Step S101: forging a zirconium alloy ingot with a preset size and a preset weight after heat preservation to obtain a forged slab with a first preset thickness;

[0041] Step S102: performing heat treatment on the forged slab;

[0042] Step S103: performing the first surface treatment on the heat-treated forged slab;

[0043] Step S104: Forging the forged slab after the first surface treatment after heat preservation to obtain a primary slab with a second preset thickness;

[0044] Step S105: performing a second surface treatment on the primary slab;

[0045] Step S106: heat-retaining the primary slab after the second surface treatment, and performing multi-pass hot rolling to obtain an intermediate slab with a third preset thick...

Embodiment 1

[0106] In this example, a Zr-4 alloy ingot with a diameter of 700 mm and a weight of 4 tons with uniform composition was used as a processing raw material to prepare a zirconium alloy hot-rolled sheet, the preparation method comprising:

[0107] S201, firstly clean the surface of the Zr-4 alloy ingot, heat it at 1050° C. for 180 minutes, and then forge to obtain a Zr-4 alloy slab with a thickness of 110 mm.

[0108] The chemical composition of the Zr-4 alloy ingot is shown in Table 1 below.

[0109] Table 1 Zr-4 alloy ingot chemical composition

[0110]

[0111] S202, under the temperature condition of 1030-1050°C, heat the forged Zr-4 alloy slab for 60-90min, and then transfer it to a quenching medium with a temperature of 30°C for quenching;

[0112] Among them, the transfer time is 45s, and the residence time of the Zr-4 alloy slab in the quenching medium is 25min;

[0113] The quenching medium is ordinary tap water;

[0114] S203, planing and milling the surface of t...

Embodiment 2

[0139] In this embodiment, a Zr-Sn-Nb alloy ingot with a diameter of 700 mm and a weight of 4 tons with uniform composition was used as a processing raw material to prepare a zirconium alloy hot-rolled plate. The preparation method includes:

[0140] S301, firstly clean the surface of the Zr-Sn-Nb alloy ingot, heat it at 1070° C. for 180 minutes, and then forge to obtain a Zr-Sn-Nb alloy slab with a thickness of 120 mm.

[0141] The chemical composition of the Zr-Sn-Nb alloy ingot is shown in Table 4 below.

[0142] Table 4 Zr-Sn-Nb alloy ingot chemical composition

[0143]

[0144] S302. Heat the forged Zr-Sn-Nb alloy slab for 120-180 minutes at a temperature of 1030-1050° C., and then transfer it to a quenching medium at a temperature of 28° C. for quenching;

[0145] Among them, the transfer time is 45s, and the residence time of the Zr-Sn-Nb alloy slab in the quenching medium is 25min;

[0146] The quenching medium is ordinary tap water;

[0147] S303, planing and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com