Comb-shaped low-slump concrete plastic-reserving agent with poly-sulphoacid structure

A technology of polysulfonic acid and plastic retaining agent, which is applied in the field of comb-shaped polysulfonic acid structure small slump concrete plastic retainer and water reducer to improve comprehensive performance, solve physical and chemical compatibility problems, and provide excellent comprehensive cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

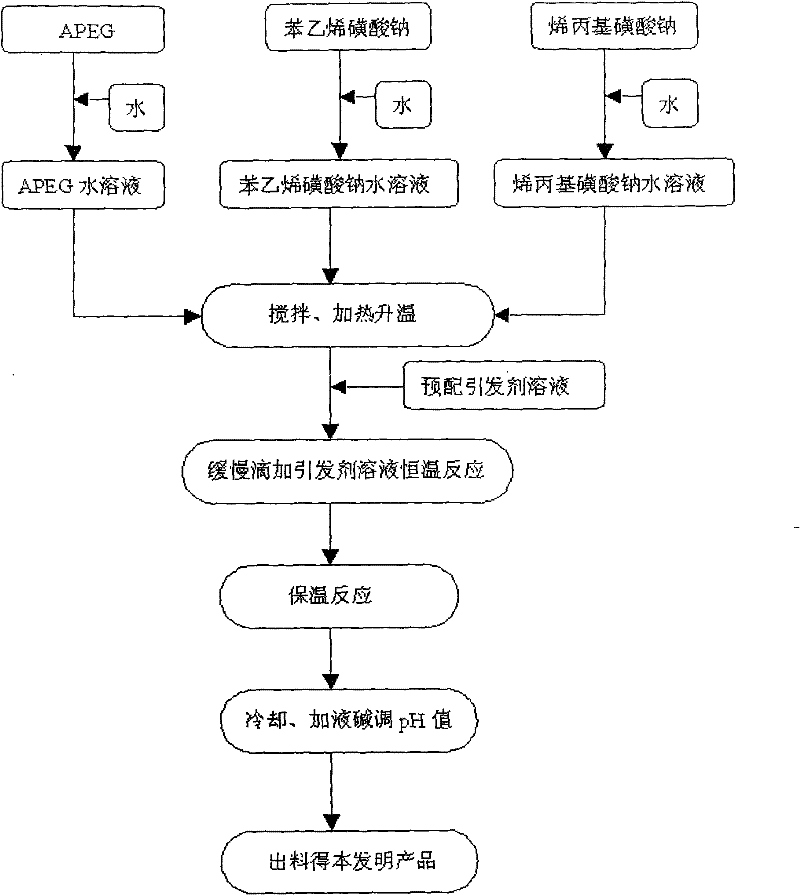

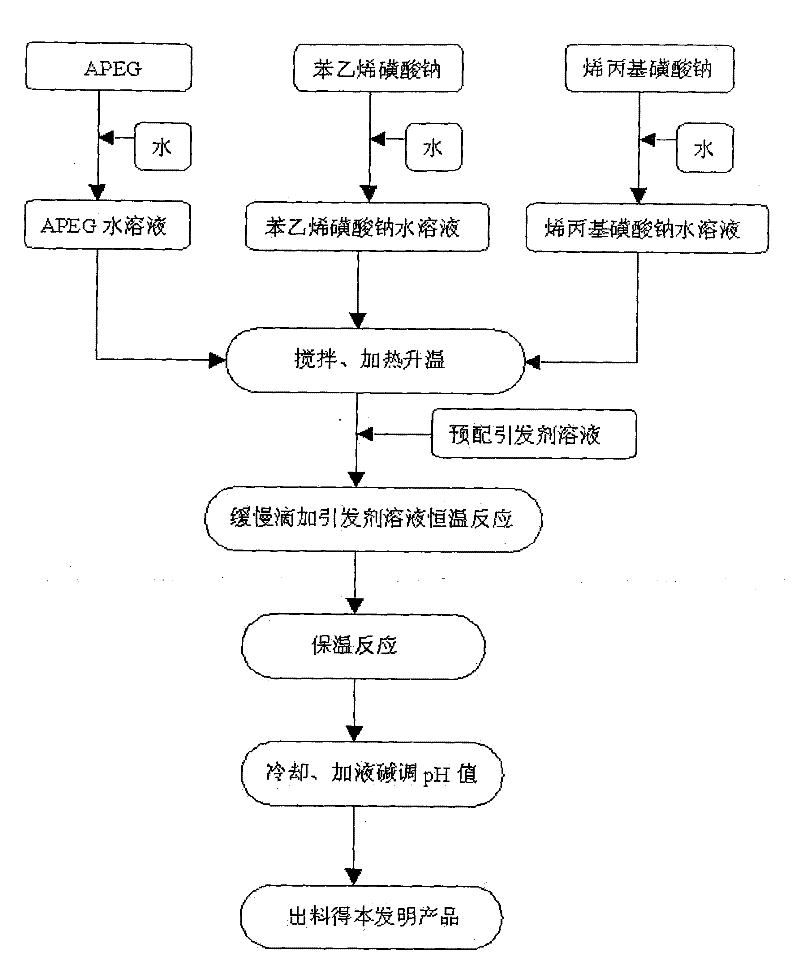

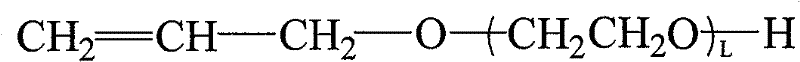

[0027] 1) Take 150g of allyl polyether (APEG1000) with an average molecular weight of 1000, and make it into a 50-70% aqueous solution; 222.73g of sodium styrene sulfonate, make it into a 20-30% aqueous solution, sodium allyl sulfonate 64.8g, made into 20-30% aqueous solution; 40g of initiator, made into 5-10% aqueous solution. All the above are weight percent concentrations.

[0028] 2) In the APEG aqueous solution, sequentially add sodium styrene sulfonate and allyl sodium sulfonate aqueous solution, then add 63g of water and stir evenly, heat up to 95°C, start adding the initiator solution dropwise, and control the drip rate of the initiator at 2 After about 1 hour, the dropwise addition is completed, and the heat preservation is continued for 1 hour, then cooled to below 40°C, neutralized by adding liquid alkali until the pH value is 7.0, and discharged to obtain the comb-shaped polysulfonic acid plastic-preserving agent of the present invention.

[0029] For comparing th...

Embodiment 2

[0034] 1) Take 150g of allyl polyether (APEG1000) and make it into a 50-70% aqueous solution; 99g of sodium styrene sulfonate, make it into a 20-30% aqueous solution; 194.4g of allyl sodium sulfonate, make it into a 20% solution ~30% aqueous solution; Initiator 47.76, made into 5~10% aqueous solution. All the above are weight percent concentrations.

[0035] 2) In the APEG aqueous solution, sequentially add sodium styrene sulfonate and allyl sodium sulfonate aqueous solution, then add 21g of water and stir evenly, heat up to 92°C, start dripping the initiator solution, and control the dripping rate of the initiator at 2 After about 1 hour, the dropwise addition is completed, continue to keep warm for 1 hour, then cool to below 40°C, add liquid alkali to neutralize until the pH value is 6.8, and discharge to obtain the comb-shaped polysulfonic acid plastic-preserving agent of the present invention.

Embodiment 3

[0037] 1) Allyl polyether (APEG1000) 150g, made into 50-70% aqueous solution; 148.49g of sodium styrene sulfonate, made into 20-30% aqueous solution; 97.2g of allyl sodium sulfonate, made into 20% ~30% aqueous solution; initiator 37.8g, made into 5~10% aqueous solution. All the above are weight percent concentrations.

[0038] 2) In the APEG aqueous solution, sequentially add sodium styrene sulfonate and allyl sodium sulfonate aqueous solution, stir evenly, heat up to 92°C, start adding the initiator solution dropwise, control the dropping rate of the initiator at about 2 hours, drop After the addition, continue to keep warm for 1 hour, then cool to below 40°C, add liquid alkali to neutralize until the pH value is 6.5, and discharge to obtain the comb-shaped polysulfonic acid plastic-preserving agent of the present invention.

[0039] The plastic-retaining agent that embodiment 1, embodiment 2 and embodiment 3 make is added in the concrete by 0.2% (the weight percent of pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com