Method for preparing slump-retaining type polycarboxylic acid series high-performance water reducing agent in one step

A polycarboxylate-based, high-performance technology, applied to the one-step preparation of concrete slump-preserving polycarboxylate-based high-performance water-reducers, in the field of slump-preserving polycarboxylate-based high-performance water-reducers The efficiency and slump retention are not very good, the production process is cumbersome, the crosslinking effect is not ideal, etc., to achieve good slump retention ability, improve slump loss, and good slump retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

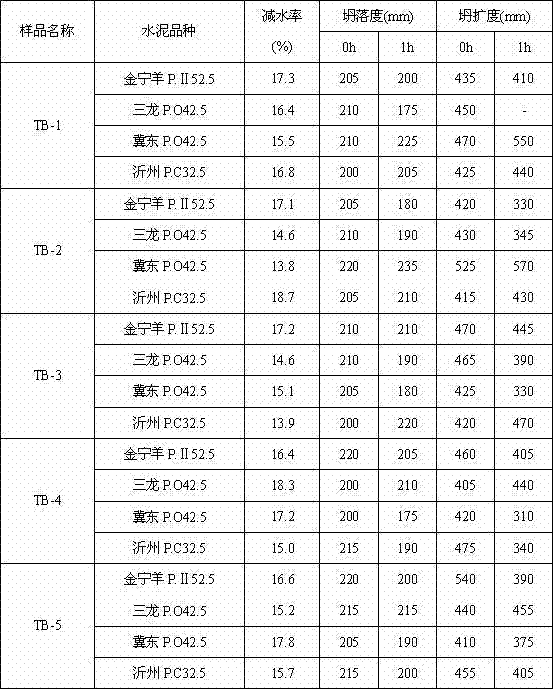

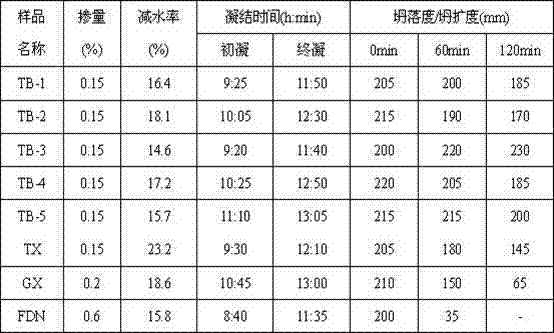

Embodiment 1

[0050] Add 390 parts of methoxy-terminated allyl polyalkylene glycol ether and 210 parts of deionized water into the reaction kettle, raise the temperature to 55°C and stir to make them all dissolve in water; then add 1.6 parts of hydrogen peroxide and stir 0.5h. Dissolve 0.7 parts of sodium sulfite in 190 parts of deionized water as dropwise addition (1); take 18 parts of acrylic acid and 3.6 parts of 2-acrylamide-2-methylpropanesulfonic acid and dissolve them in 170 parts of deionized water as dropwise addition ( 2); within 3h~4h, drop evenly into the reactor at the same time, and ensure that the dropwise addition (1) is completed 0.5h later than the dropwise addition (2). After the addition, keep stirring at 55°C for 1.5h, cool down to room temperature and add 18 parts of 30% liquid caustic soda, continue stirring for 0.5h to obtain the product (TB-1).

Embodiment 2

[0052] Add 340 parts of butoxy-terminated allyl polyalkylene glycol ether and 210 parts of deionized water into the reaction kettle, raise the temperature to 65°C and stir to make them all dissolve in water; then add 1.4 parts of hydrogen peroxide and stir 0.5h. Dissolve 0.9 parts of sodium ascorbate in 200 parts of deionized water as dropwise addition (1); take 30 parts of methacrylic acid and 6.2 parts of sodium methacrylate sulfonate and dissolve them in 185 parts of deionized water as dropwise addition (2); Within 3h~4h, drop evenly into the reactor at the same time, and ensure that the dropwise addition (1) is 0.5h later than the dropwise addition (2). After the addition, keep stirring at 65°C for 2 hours, add 26 parts of ethanolamine, and continue stirring for 0.5 hours to obtain the product (TB-2).

Embodiment 3

[0054] Add 380 parts of ethoxy-capped allyl polyalkylene glycol ether and 220 parts of deionized water into the reaction kettle, raise the temperature to 75°C and stir to make them all dissolve in water; then add 2.5 parts of tert-butyl Hydrogen peroxide was stirred for 0.5h. Take 1.0 parts of ascorbic acid dissolved in 180 parts of deionized water as dropwise (1); take 10 parts of acrylic acid, 8 parts of hydroxyethyl methacrylate and 3.5 parts of sodium allyl sulfonate dissolved in 145 parts of deionized water as drop

[0055] Add (2); within 3h~4h, drop evenly into the reactor at the same time, and ensure that the dropwise addition of (1) is 0.5h later than the dropwise addition of (2). After the addition, keep stirring at 75°C for 2 hours, add 35 parts of 30% liquid caustic soda, and continue stirring for 0.5 hours to obtain the product (TB-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com