Preparation method of carbon nanotube-loaded titanium oxide photocatalyst

A technology of photocatalysts and carbon nanotubes, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Problems such as difficulty in powder recovery, to achieve the effect of improving superiority, stable structure, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

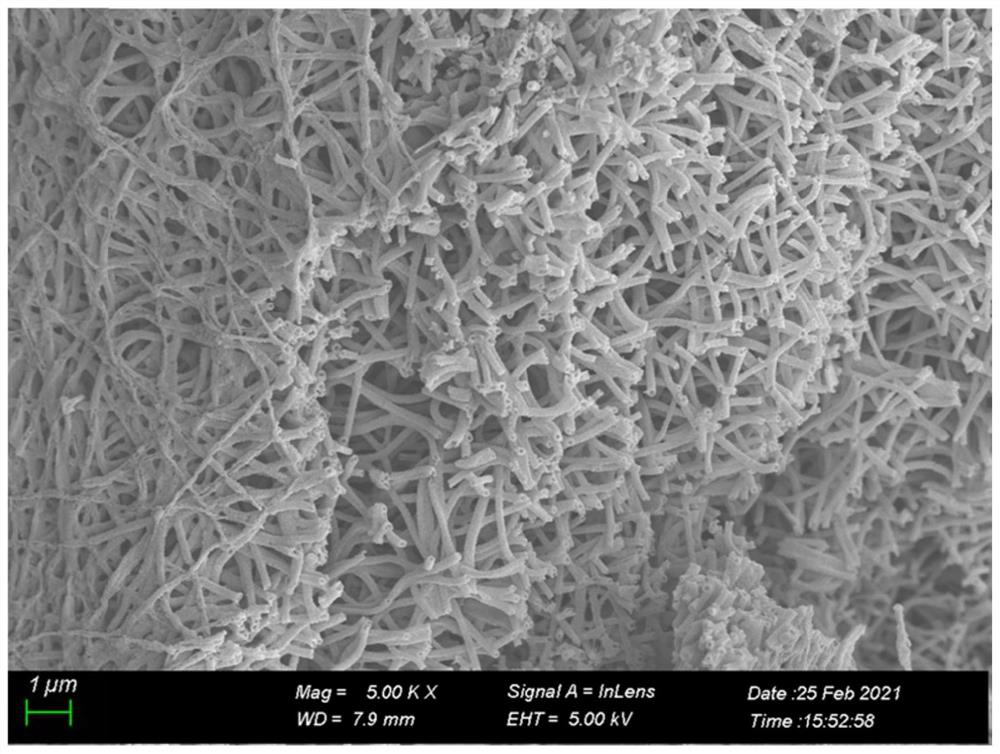

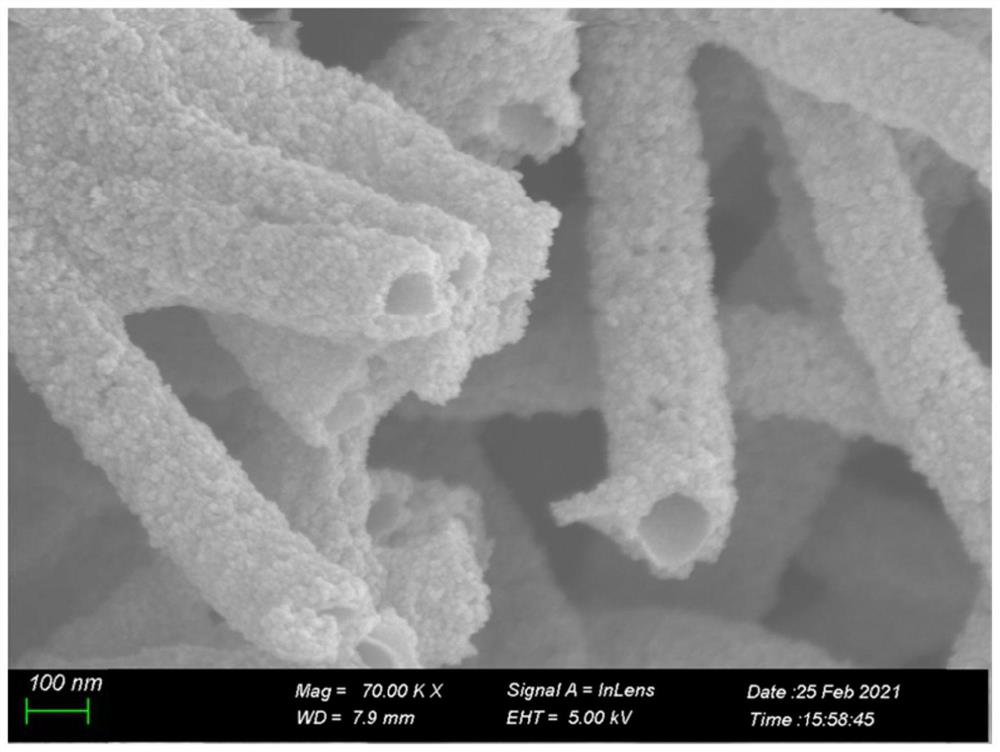

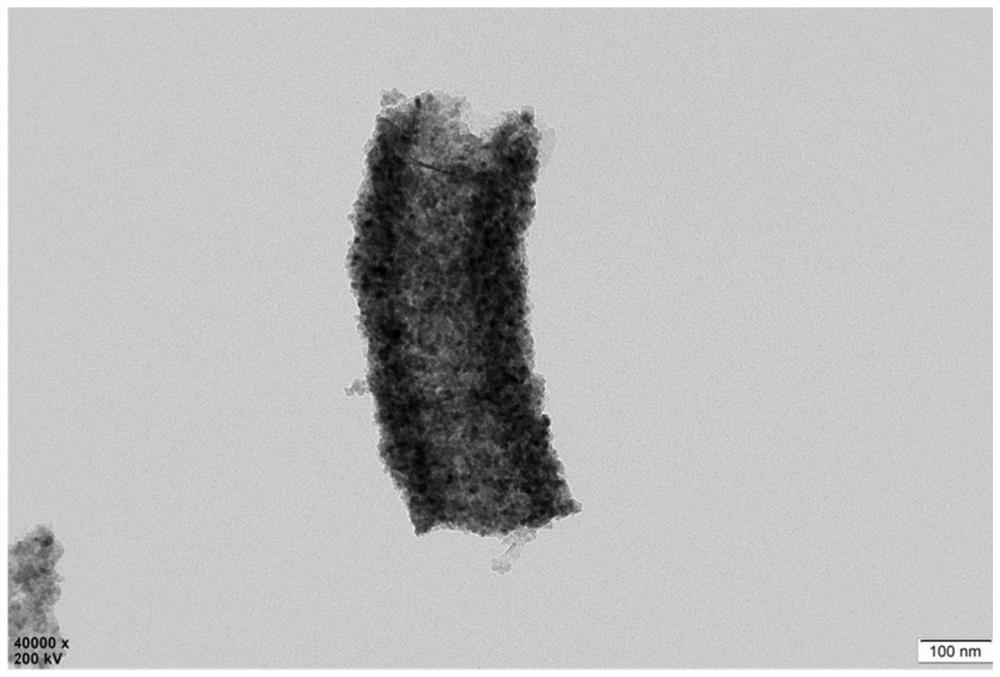

[0048] The preparation method of the titanium oxide photocatalyst supported by carbon nanotubes proposed by the present invention comprises the following steps and content:

[0049] (1) First, dissolve 1-2.5g of analytically pure polyacrylonitrile powder with a molecular weight of 100,000-150,000 and 0.03-0.15g of ammonium fluoride in 15mL of N,N-dimethylformamide, and keep warm at 50-60°C Stir magnetically for 10-12 hours under the same conditions to obtain a transparent solution that is fully dissolved and uniformly dispersed;

[0050] (2) Then the solution obtained in step (1) is placed in a syringe, and the polyacrylonitrile fiber membrane containing ammonium fluoride is prepared by electrospinning, and it is set aside;

[0051] (3) Then mix 1.8-9.6g of analytically pure tetrabutyl titanate and 3-5mL of analytically pure glacial acetic acid in 40-80mL of absolute ethanol, and stir magnetically at room temperature for 20-40min to obtain a uniformly mixed solution; (2) 0.1-...

Embodiment

[0061]Example: 1.5 g of analytically pure polyacrylonitrile powder with a molecular weight of 150,000 and 0.1 g of ammonium fluoride were dissolved in 15 mL of N,N-dimethylformamide, and magnetically stirred at 60° C. for 12 hours to obtain a transparent solution. Then use a 10mL syringe to draw 10mL of the above-mentioned solution, install No. 22 flat metal needles, set the spinning parameters as: spinning voltage 18kV, spinning temperature 35°C, humidity 45%, the distance between the syringe needle and the receiving device for spinning is 15cm, the rotational speed of the receiving roller is 55rpm, and the flow rate of the solution is 0.0016mm / s; spin to obtain a white fiber membrane for use. Then, add 50mL of absolute ethanol, 4mL of glacial acetic acid and 6.6g of tetrabutyl titanate into a 100mL beaker, stir magnetically for 40min at room temperature and mix well; then transfer to a hydrothermal reaction kettle with a capacity of 100mL, and add The ammonium fluoride polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com