a use of ch 4 A direct reduction process for the production of sponge iron by non-catalytic oxygen-enriched conversion

A non-catalytic, sponge iron technology, applied in the field of iron or steel smelting, can solve the problems of long process flow, easy bonding of sponge iron, complex process route, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Production of Sponge Iron by Reducing Titanium Vanadium Magnetite

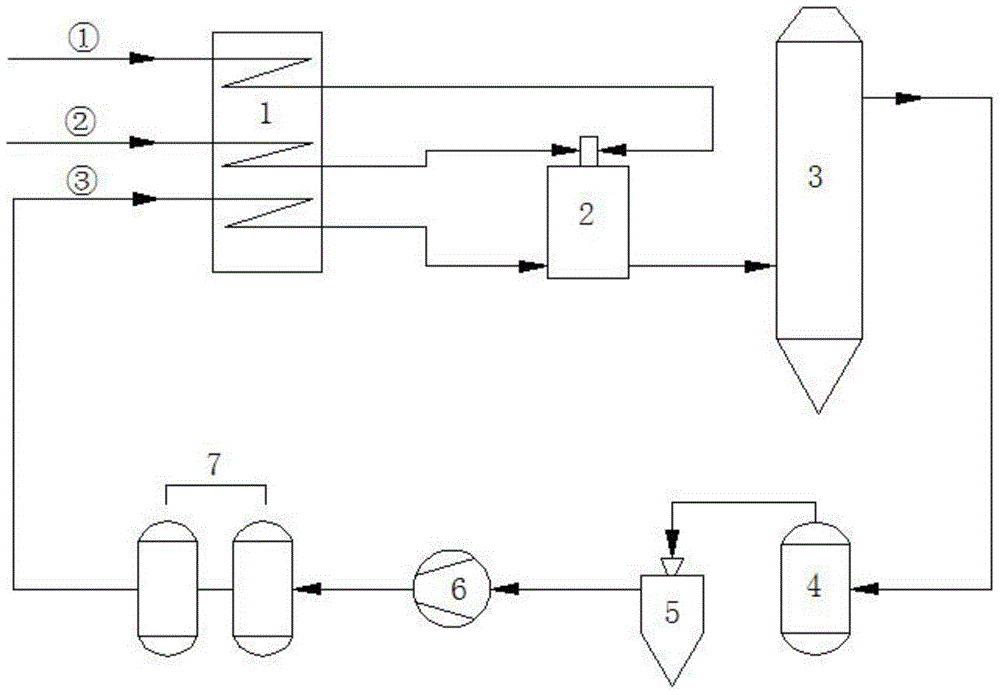

[0048] Coke oven gas is purified and pressurized as CH-rich 4 The raw material gas and oxygen-enriched air are preheated respectively through the tubular heating furnace, and the CH-enriched air 4 The raw material gas is preheated to 400°C, and the oxygen-enriched air is preheated to 250°C; after preheating, the two gases enter the non-catalytic oxygen-enriched reformer for combustion reaction and heat up, and the CH 4 into CO and H 2 , forming a high-temperature reformed gas with a temperature of 1340°C.

[0049] Simultaneously with the above, the furnace top gas from the shaft furnace that is reduced to form sponge iron is cooled to 210°C through a heat exchanger, then enters the washing tower, is washed with water and dedusted and cooled to 40°C, and then pressurized to 0.45MPa by a pressurizer and then enters a vacuum The pressure swing adsorption hydrogen purification device (VPSA) produces puri...

Embodiment 2

[0055] Reduction of ordinary iron ore to make sponge iron

[0056] Natural gas is purified and pressure-regulated as CH-rich 4 The raw material gas and oxygen-enriched air are preheated respectively through the tubular heating furnace, and the CH-enriched air 4 The raw material gas is preheated to 350°C, and the oxygen-enriched air is preheated to 260°C; after preheating, the two gases enter the non-catalytic oxygen-enriched reformer for combustion reaction and heat up, and the CH 4 into CO and H 2 , forming high-temperature reformed gas at a temperature of 1350°C.

[0057] Simultaneously with the above, the furnace top gas from the shaft furnace that is reduced to form sponge iron is cooled to 210°C through a heat exchanger, then enters the washing tower, is washed with water and dedusted and cooled to 40°C, and then pressurized to 0.8MPa by a pressurizer and then enters a vacuum The pressure swing adsorption hydrogen purification device (VPSA) produces purified hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com