High-temperature thermal extrusion moulding method of TiAl intermetallic compound material

An intermetallic compound and extrusion forming technology, which is applied in the direction of metal extrusion dies, etc., can solve the problems of difficult extrusion forming, fast heat dissipation of billets, and large deformation resistance, so as to reduce the preheating temperature and actual working temperature, and is easy to clean , The effect of small deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

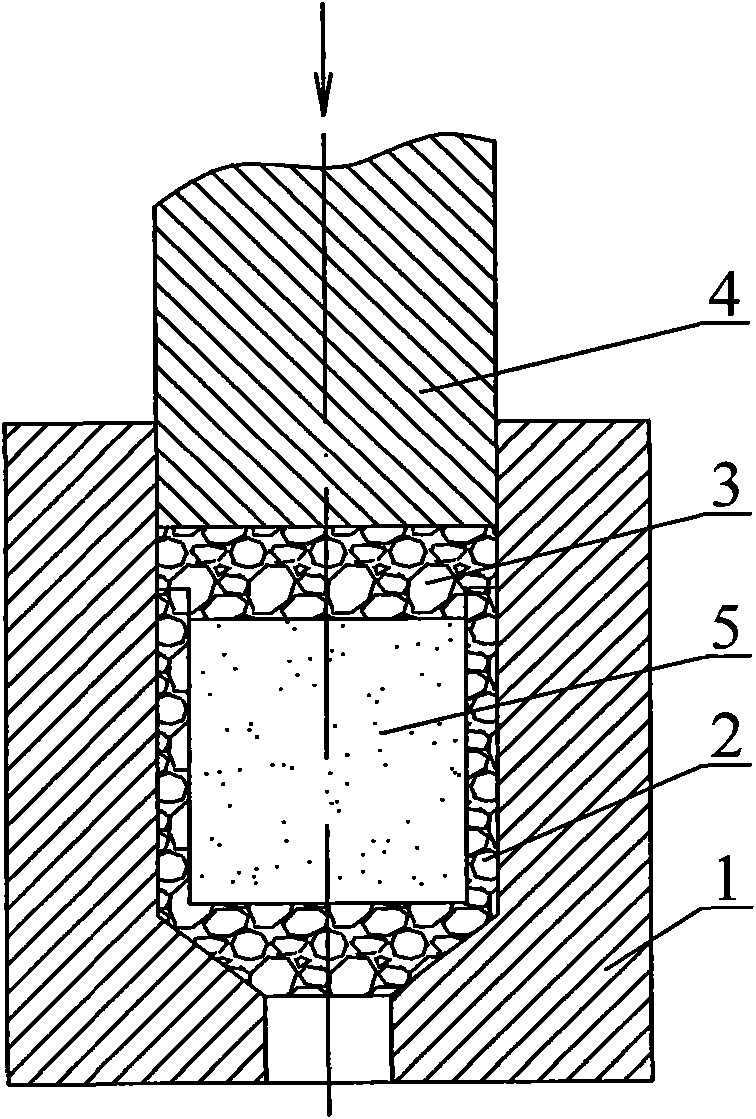

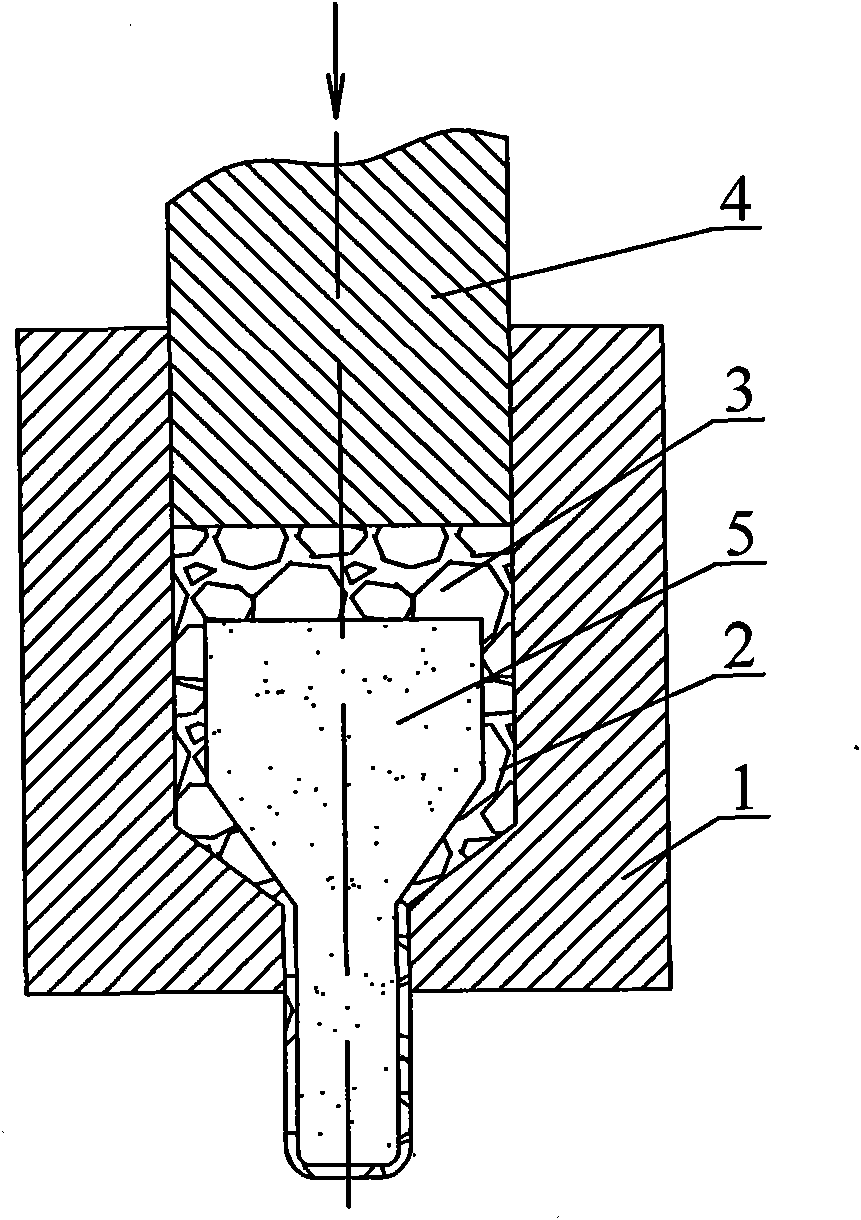

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment is realized through the following steps: The described method is realized through the following steps: Step 1, make extruded sheath 2 and sheath cover 3: extrude sheath 2 and sheath cover 3 The raw materials are all composed of 40%-60% graphite powder, 30%-50% low-melting glass powder and 5%-15% hollow floating bead powder according to the weight percentage. Example preparation, mixing in a powder mixer or a ball mill, on a mechanical press, use a mold to press the mixed extrusion sheathing powder raw material into a shape and size of the inner cavity that matches the shape of the TiAl intermetallic compound extrusion billet 5 and the upper end It is an open extruded sheath 2; the raw materials of the sheath cover 3 are prepared according to the above weight percentage, mixed in a powder mixer or a ball mill, and pressed on a mechanical press by using a mold to co...

specific Embodiment approach 2

[0008] Specific embodiment two: the TiAl intermetallic compound extrusion billet 5 described in step one of this embodiment is Ti 3 Al, Ti 2 Al, TiAl, TiAl 3 or TiAl 2 Nb. The above materials are Ti-Al intermetallic compound materials. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: When heating the TiAl intermetallic compound extrusion billet 5 described in step 3 of this embodiment, argon gas is filled into the heating furnace. Doing so can prevent the oxidation of the TiAl intermetallic compound extrusion billet 5 at a high temperature of 1150°C to 1300°C. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com