In-situ particle mixed reinforced aluminum-based composite material and preparation method thereof

A composite material and reinforced aluminum-based technology, which is applied in the field of composite materials with aluminum alloy as the matrix and its preparation, can solve the problems of difficult to obtain high volume fraction particles, difficult to achieve reinforcement, high volume fraction, etc., and meet the requirements of ensuring lightweight , meet the performance requirements, and improve the effect of volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

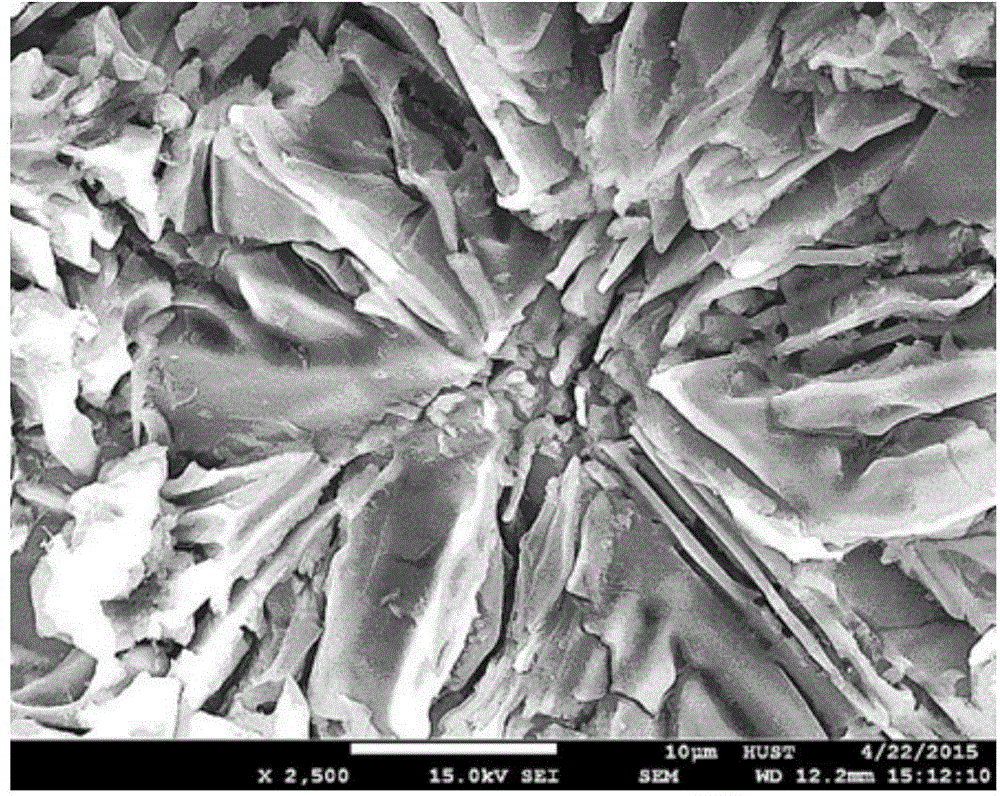

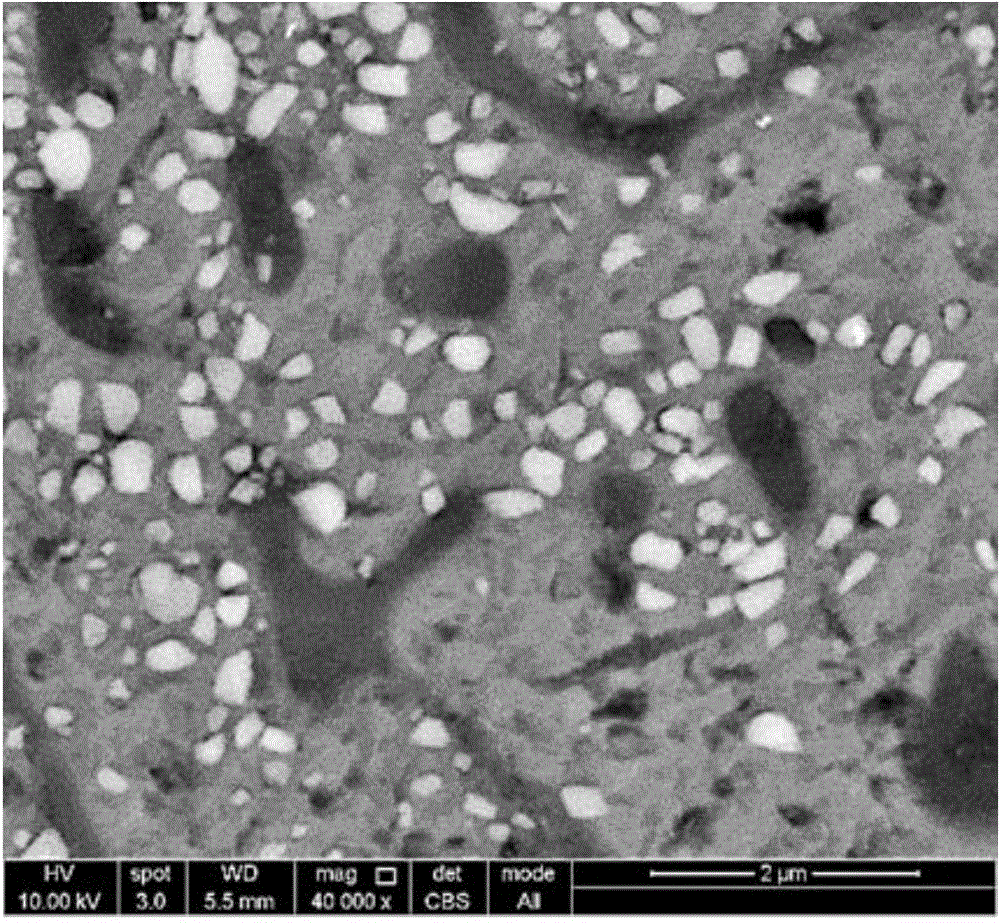

Embodiment 1

[0037] KBF 4 with K 2 TiF 6 According to the proportion of Ti, B molar ratio about 2:1. Dry the mixed salt at 150°C for 10 hours; the mixed salt should be preheated at 280°C before the experiment. Put pure Al into the smelting furnace, add 2% mass fraction of pure Mg after melting, and then superheat the alloy melt to 800°C, the obtained alloy composition is Al-2Mg. Turn on mechanical stirring afterwards, the speed of mechanical stirring is 360r / min, add the mixed salt of pretreatment heat preservation in the melt of mechanical stirring, the total addition amount of mixed salt is 40% of alloy melt. After adding the mixed salt, keep the temperature at 800°C for 40 minutes. Get TiB 2 The volume fraction is 1%. Afterwards, the reaction salt slag was removed, and the temperature was lowered to 700°C, and the Al-25% Si master alloy and Mg were successively added to the melt for melting, and the amount of addition made the Mg 2 Si final volume fraction is 10%. Keep warm for ...

Embodiment 2

[0039] KBF 4 with K 2 TiF 6 According to the proportion of Ti, B molar ratio about 2:1. Dry the mixed salt at 175°C for 8 hours; the mixed salt is fully mixed by a mixer. The mixed salt should be preheated at 300°C before the experiment. Put pure Al into the smelting furnace, add 2% mass fraction of pure Mg after melting, and then superheat the alloy melt to 900°C, and the obtained alloy composition is Al-2Mg. Turn on mechanical stirring afterwards, the speed of mechanical stirring is 720r / min, add the mixed salt of pretreatment heat preservation in the melt of mechanical stirring, the total amount of mixed salt added is 120% of alloy melt. After adding the mixed salt, keep the temperature at 900°C for 60 minutes. Get TiB 2 The volume fraction is 10%. Afterwards, the reaction salt slag was removed, and the temperature was lowered to 750°C, and the Al-25% Si master alloy and Mg were successively added to the melt for melting, and the amount of addition made the Mg 2 Si ...

Embodiment 3

[0041] KBF 4 with K 2 TiF 6 According to the proportion of Ti, B molar ratio about 2:1. Dry the mixed salt at 160°C for 15 hours; use a ball mill to mill the mixed salt to reduce the particle size and mix evenly. The mixed salt should be preheated at 270°C before the experiment. Put pure Al into the smelting furnace, add 2% mass fraction of pure Mg after melting, and then superheat the alloy melt to 700°C, and the obtained alloy composition is Al-2Mg. Afterwards, the mechanical stirring is started, and the speed of the mechanical stirring is 800r / min. The mixed salt for pretreatment and heat preservation is added to the mechanically stirred melt, and the total amount of the mixed salt added is 80% of the alloy melt. After adding the mixed salt, keep warm at 860°C, and keep stirring at 800r / min for 30min. Get TiB 2 The volume fraction is 5%. Afterwards, the reaction salt slag was removed, and the temperature was lowered to 750°C, and the Al-25% Si master alloy and Mg wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com