Lightweight structure for automobile wheel hub motor

A lightweight technology for automobile hubs, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as easy deviation between hubs and withdrawal motors, affect safety and service life, and poor heat dissipation performance, etc., to achieve guaranteed Effects of weight reduction, weight reduction, and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

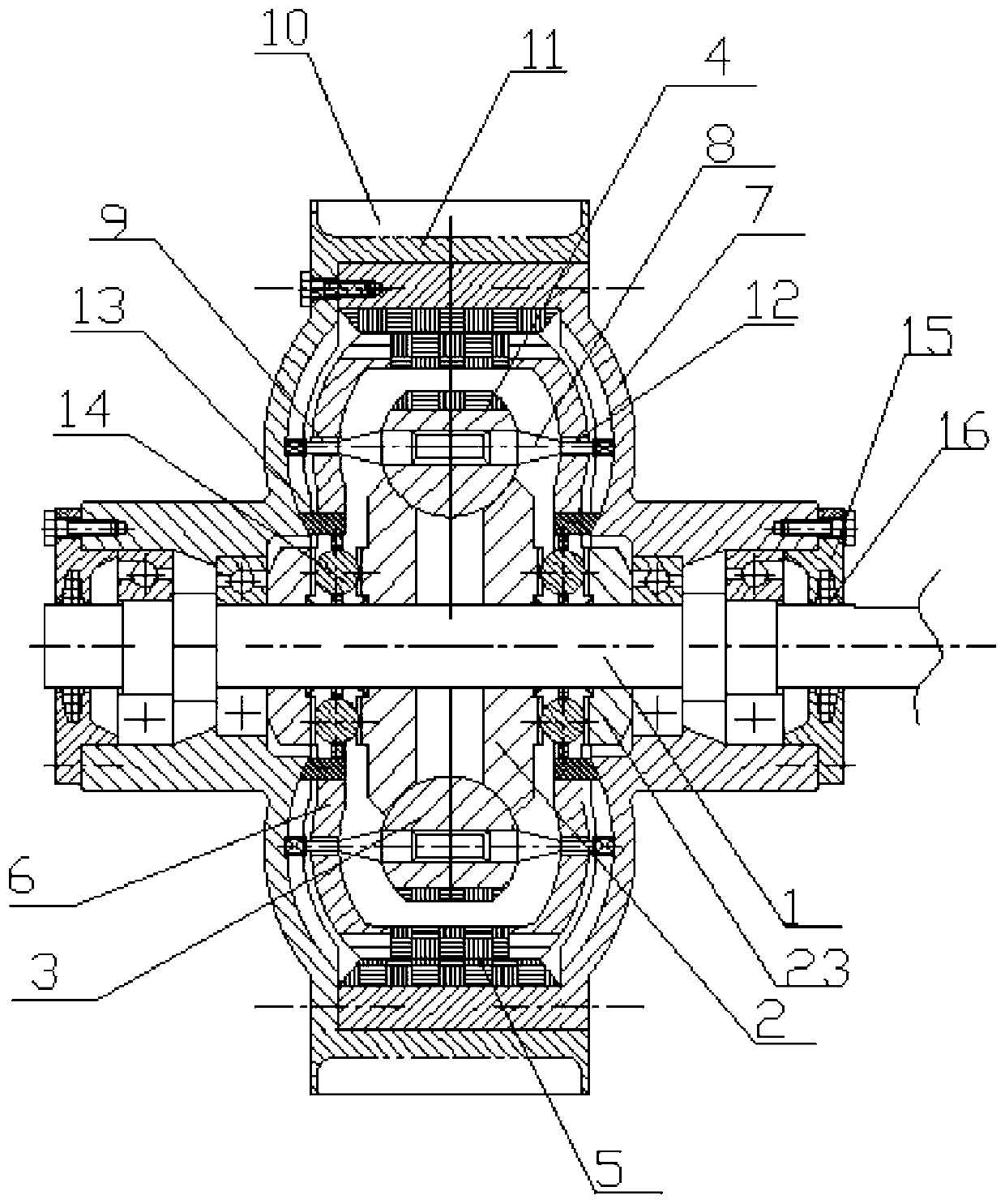

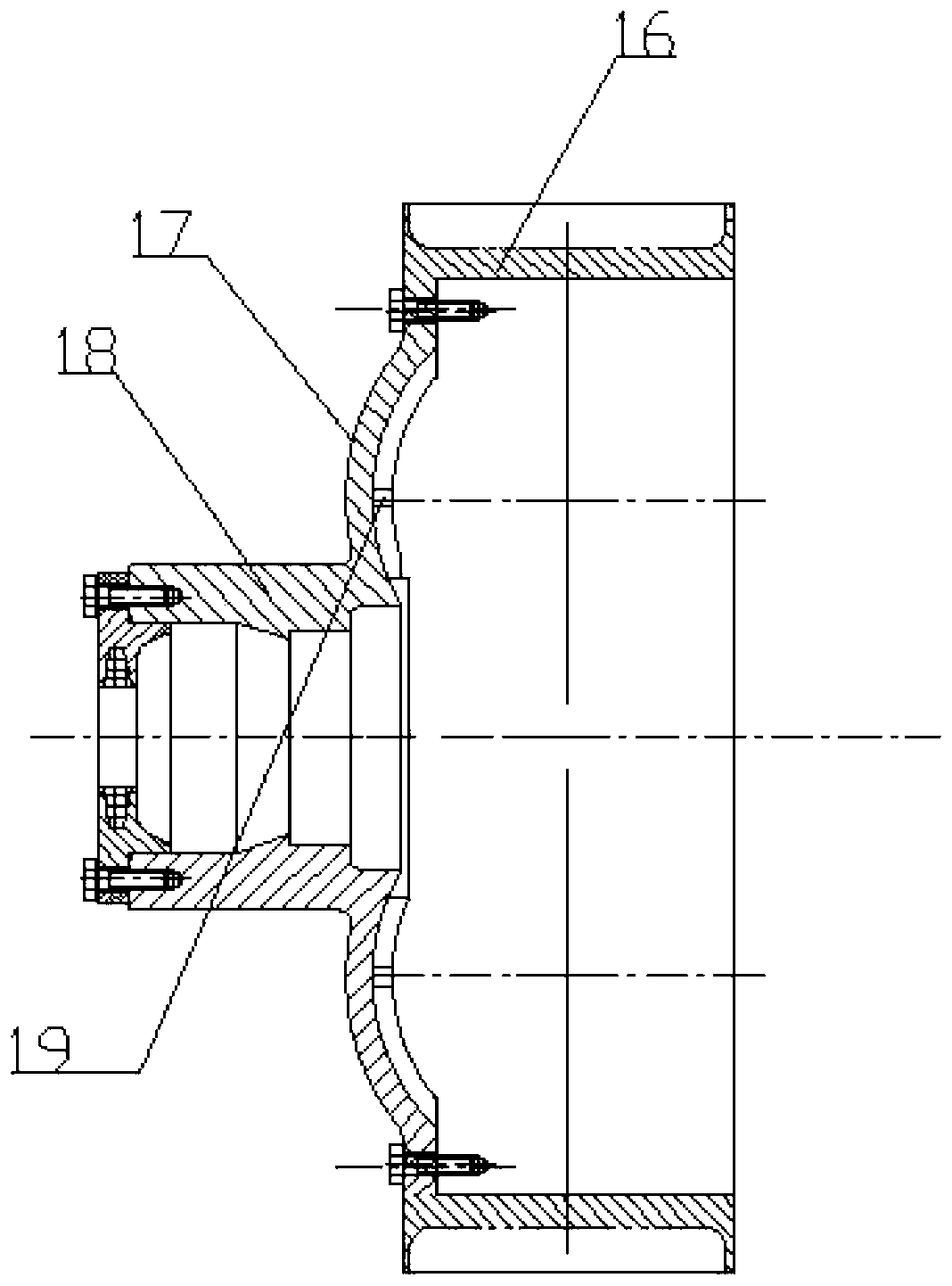

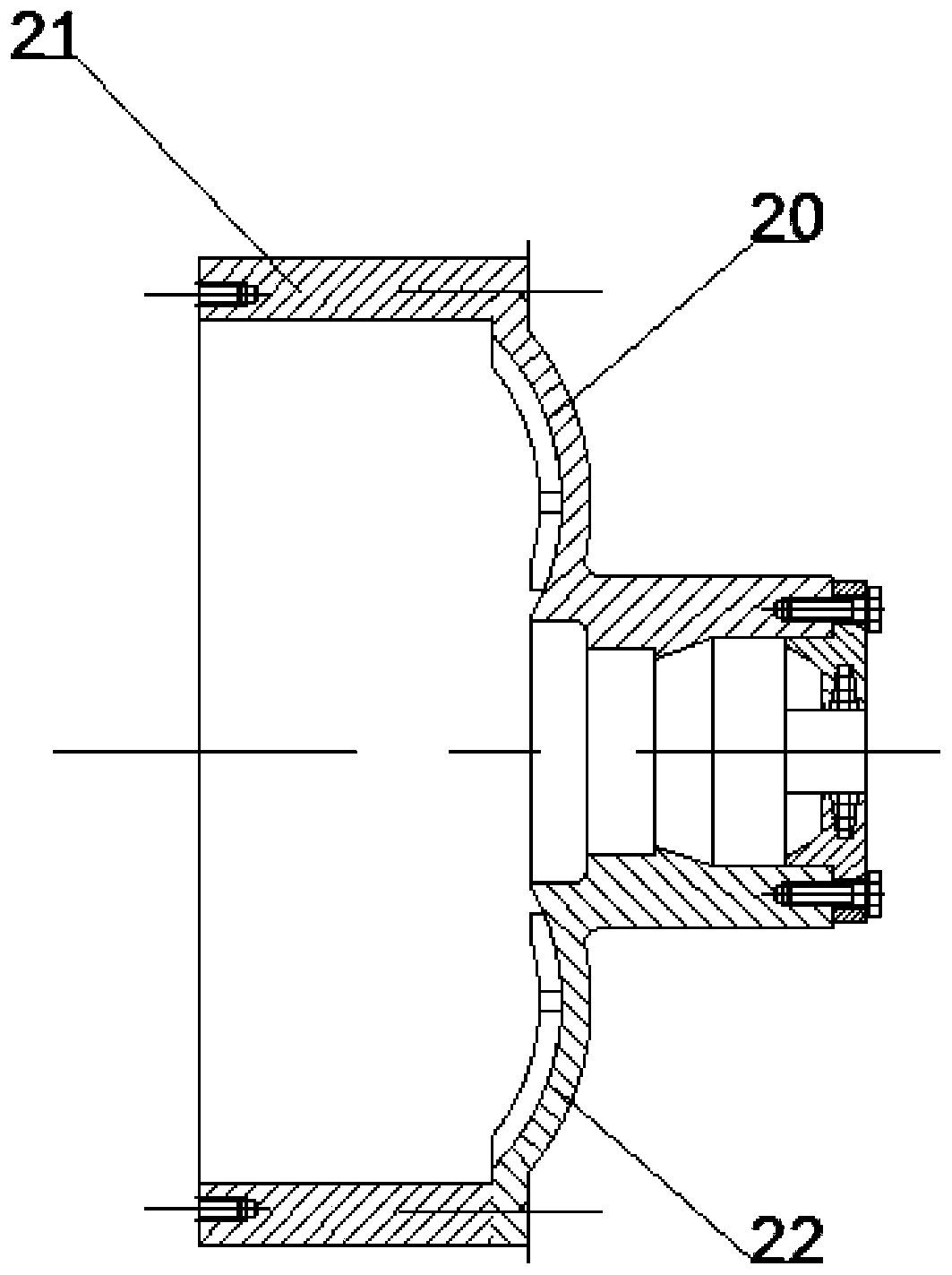

[0022] see Figure 1~3 , in an embodiment of the present invention, a lightweight structure for an automobile hub motor, comprising an outer hub 11, an inner clamping hub 7, an outer rotor 5, an inner stator 4, and a main shaft 1, wherein the outer periphery of the outer hub is provided with a fixed The seat 10 of the tire, the inner clamping hub 7 is fitted and fixed in the outer hub 11 and is fixedly connected with the outer hub 11 by bolts, the center of the outer hub 11 and the inner clamping hub 7 is supported by a bearing The main shaft 1 is characterized in that a driving cavity is formed between the outer hub 11 and the inner clamping hub 7, and a positioning seat 2 fixed on the main shaft is arranged in the driving cavity. The inner stator 4 is fixedly arranged on the stator seat 3, the outer rotor 5 is fixedly arranged on the inner side of the inner clamping hub 7, the outer rotor and the inner stator are configured as a direct drive motor, and the outer hub 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com