Vehicle body structure capable of resisting small offset impact and casting method of front connecting piece

A connecting piece and small offset technology, applied in the substructure, superstructure, vehicle components, etc., can solve the problems of single collision force transmission path, difficult to resist small offset collision, etc., to ensure safety, ensure the lightweight of the body, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

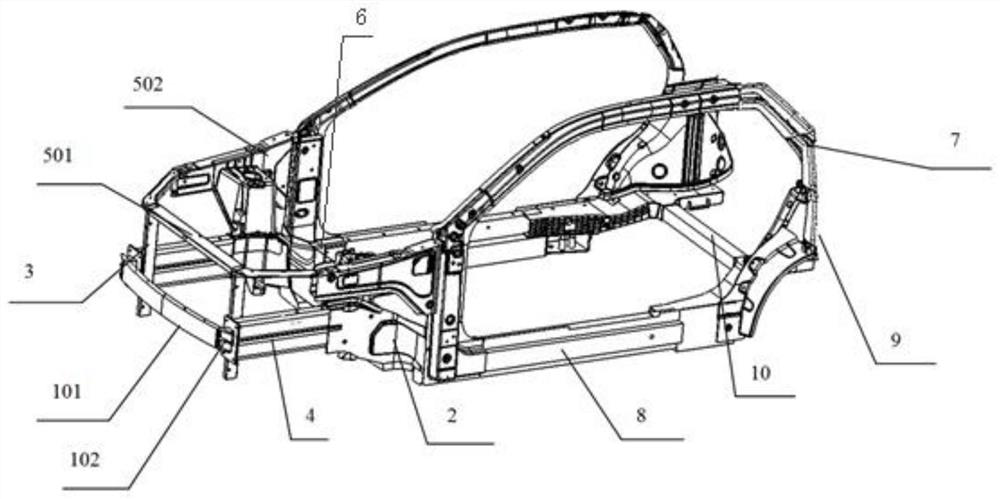

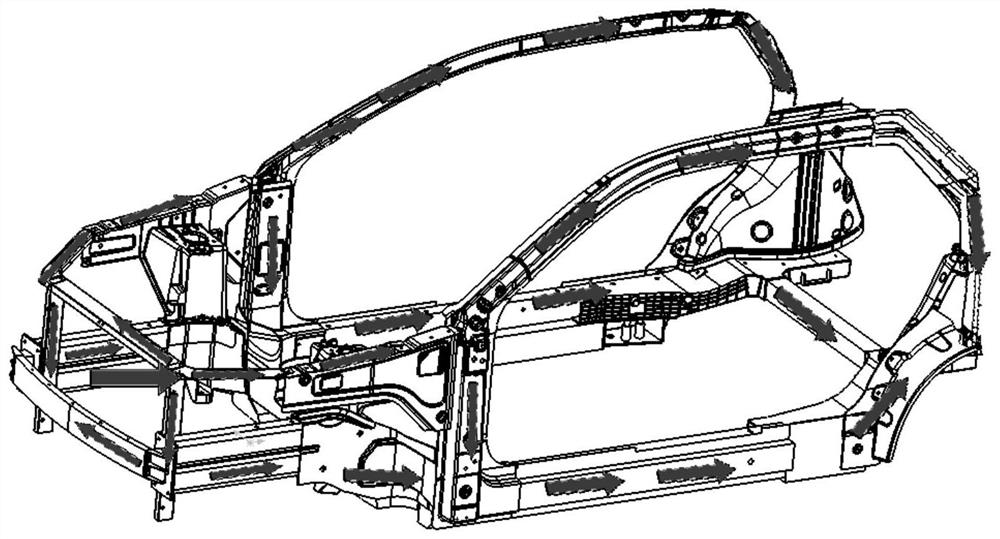

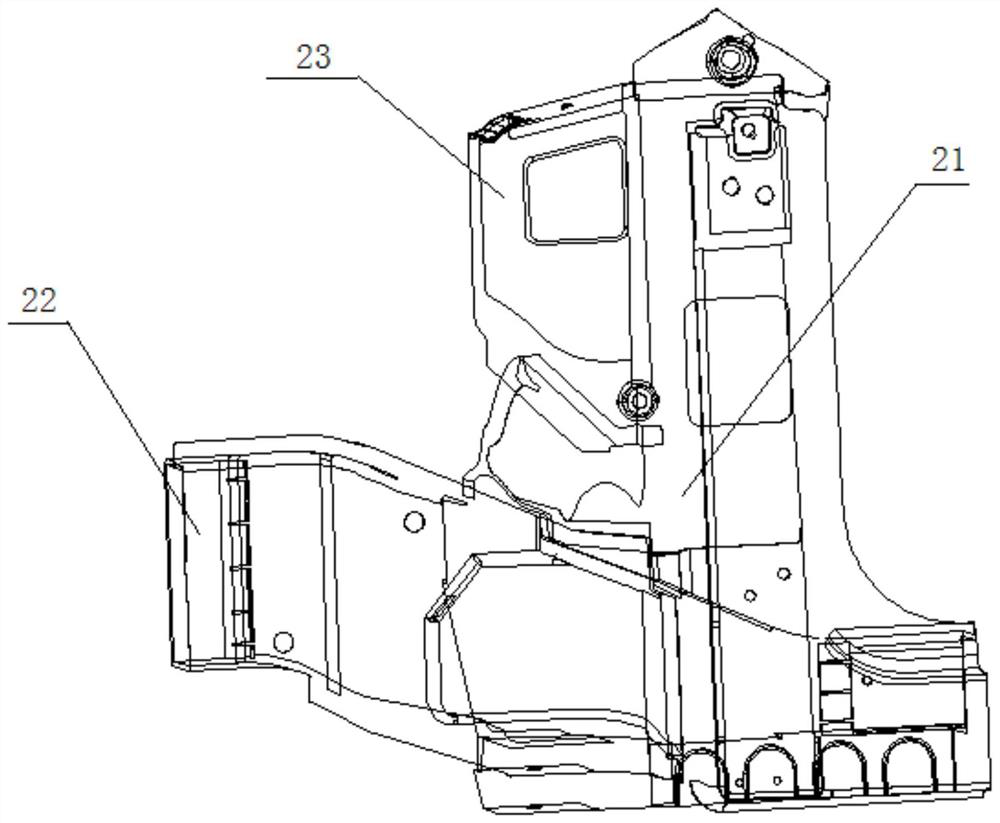

[0035] Such as figure 1 As shown, a vehicle body structure resistant to small offset collisions includes a front anti-collision beam 101, a front longitudinal beam 4 symmetrically arranged along the front anti-collision beam 101, and a force-uploading path structure located above the front anti-collision beam 101. An energy-absorbing box 102 is arranged between the front longitudinal beam 4 and the front anti-collision beam 101. It is characterized in that the force-uploading path structure includes an upper beam 501 and a body side structure arranged symmetrically along the upper beam 501. The body side structure It includes a vertical connecting beam 3, an upper longitudinal beam 502, a front connecting piece 2 and an integrated side panel 7, one end of the vertical connecting beam 3 is connected to the front longitudinal beam 4, and the other end is connected to the upper longitudinal beam 502, the One end of the upper longitudinal beam 502 is connected to the upper cross m...

Embodiment 2

[0047] A method for casting a front connector 2 of a vehicle body structure resistant to small offset bumps, comprising the following steps:

[0048] S1. Mix and melt the aluminum alloy material, and preheat the mold for casting at 180-220°C;

[0049] S2. Inject the mixed and smelted aluminum alloy material into the preheated mold, and then close the mold;

[0050] S3. Inject oxygen into the injection cavity and cavity of the mould, make the oxygen fill the injection cavity and the cavity and get rid of the rest of the gas, so that the aluminum and oxygen react to form dispersed aluminum oxide particles;

[0051] S4. Push the molten aluminum alloy material to fill the cavity through the injection punch, end the pressurization and demould after the metal solidifies.

[0052] In this embodiment, the above-mentioned casting method is used to cast the front connector 2 of the vehicle body structure. Before the injection process, oxygen is injected into the injection cavity and th...

Embodiment 3

[0056] A method for casting a front connector 2 of a vehicle body structure resistant to small offset bumps, comprising the following steps:

[0057] S1. Mix and melt the aluminum alloy material, and preheat the mold for casting at 180-220°C;

[0058] S2. Inject the mixed and smelted aluminum alloy material into the preheated mold, and then close the mold;

[0059] S3. Inject oxygen into the injection cavity and cavity of the mould, make the oxygen fill the injection cavity and the cavity and get rid of the rest of the gas, so that aluminum and oxygen react to form dispersed aluminum oxide particles;

[0060] S4. Push the molten aluminum alloy material to fill the cavity through the injection punch, end the pressurization and demould after the metal solidifies.

[0061]Specifically, the aluminum alloy material is calculated by mass fraction: 7% of silicon element, 0.5% of magnesium element, 2% of zinc element, 0.4% of copper element, 0.75% of nickel element, 0.75% of tin elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com