Multilayer composite plate used for motor home box bodies

A multi-layer composite and box technology, which is applied in the direction of layered products, vehicle parts, metal layered products, etc., can solve the problem of weak deformation resistance of the panel inside the box, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

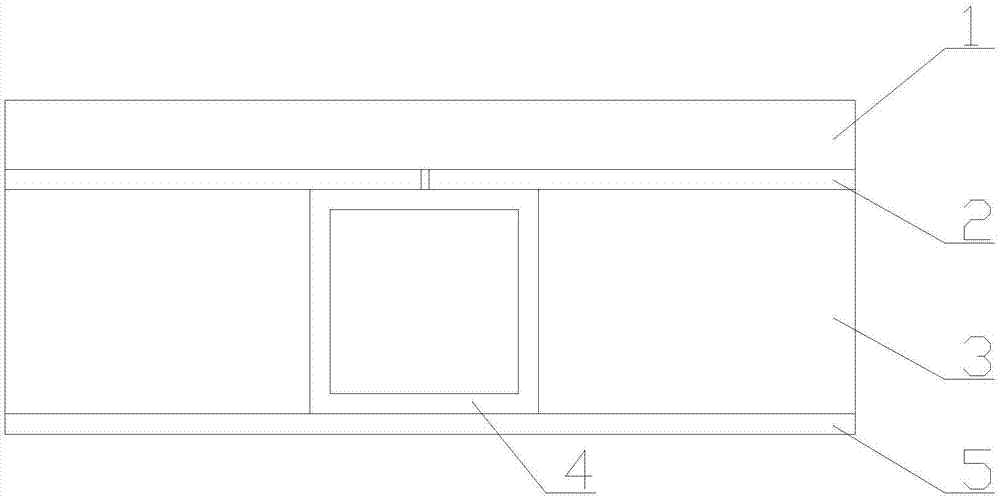

[0010] Such as figure 1 As shown, a multi-layer composite board used for a caravan box includes an inner plywood 1, a middle heat insulation layer 3 and an outer panel. The outer panel can be set as a weather-resistant gel-coated glass steel plate 5, which not only reduces weight, but also can reflect light and achieve a certain temperature insulation effect. A layer of reinforced aluminum plate 2 is added between the plywood 1 and the heat insulation layer 3 , and the reinforced aluminum plate 2 is covered and arranged at the splicing seam of the plywood 1 . An aluminum frame 4 is added in the heat insulating layer 3 . Since there is also a splicing gap between the reinforced aluminum plates 2 , the position of the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com