High heat-conducting copper-based composite material and preparation method thereof

A copper-based composite material, high thermal conductivity technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of difficulty in preparing thin-walled complex devices, poor interface bonding, and increasing material thermal resistance. and other problems, to achieve the effect of small thermal expansion coefficient, reduction of thermal stress, and reduction of interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

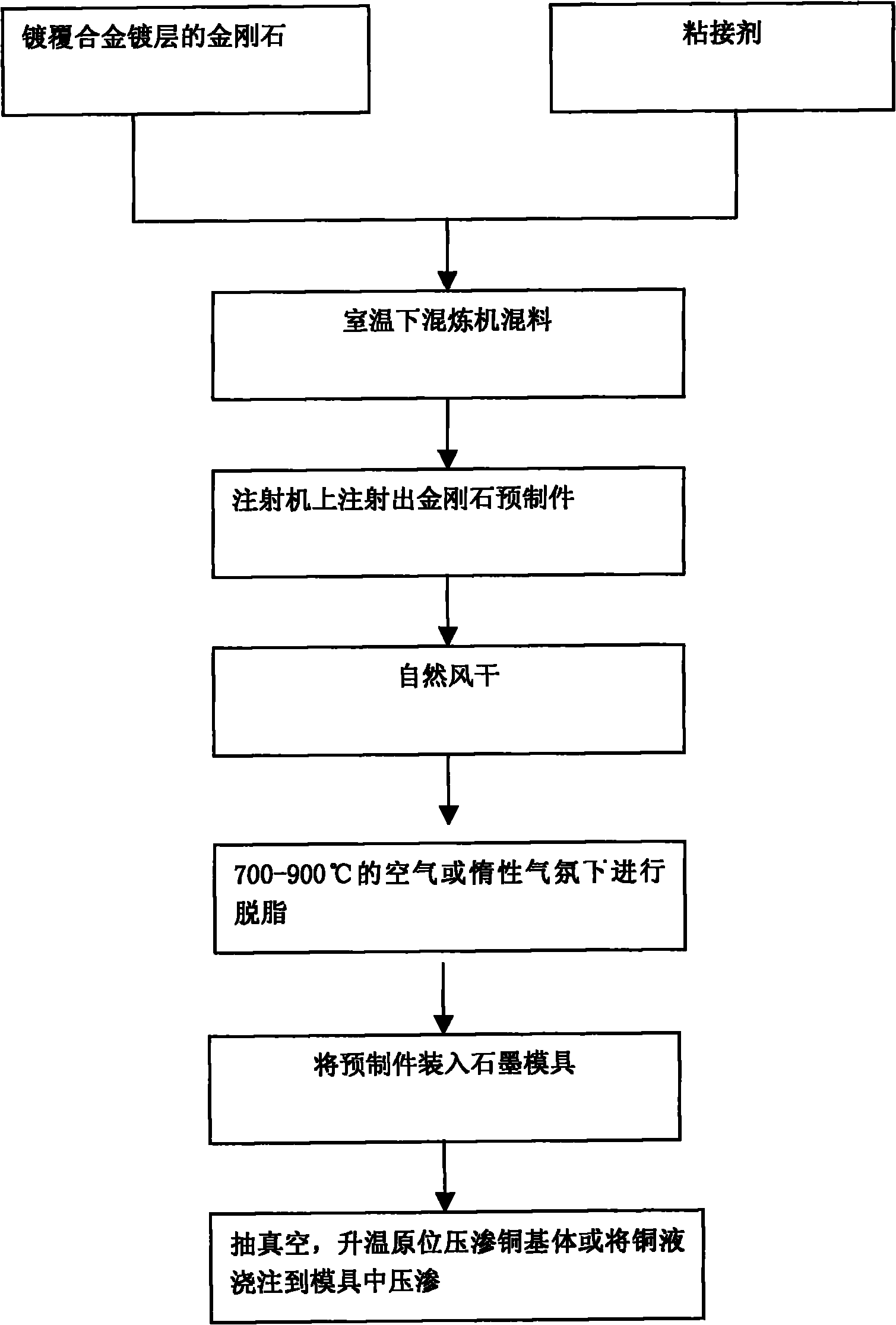

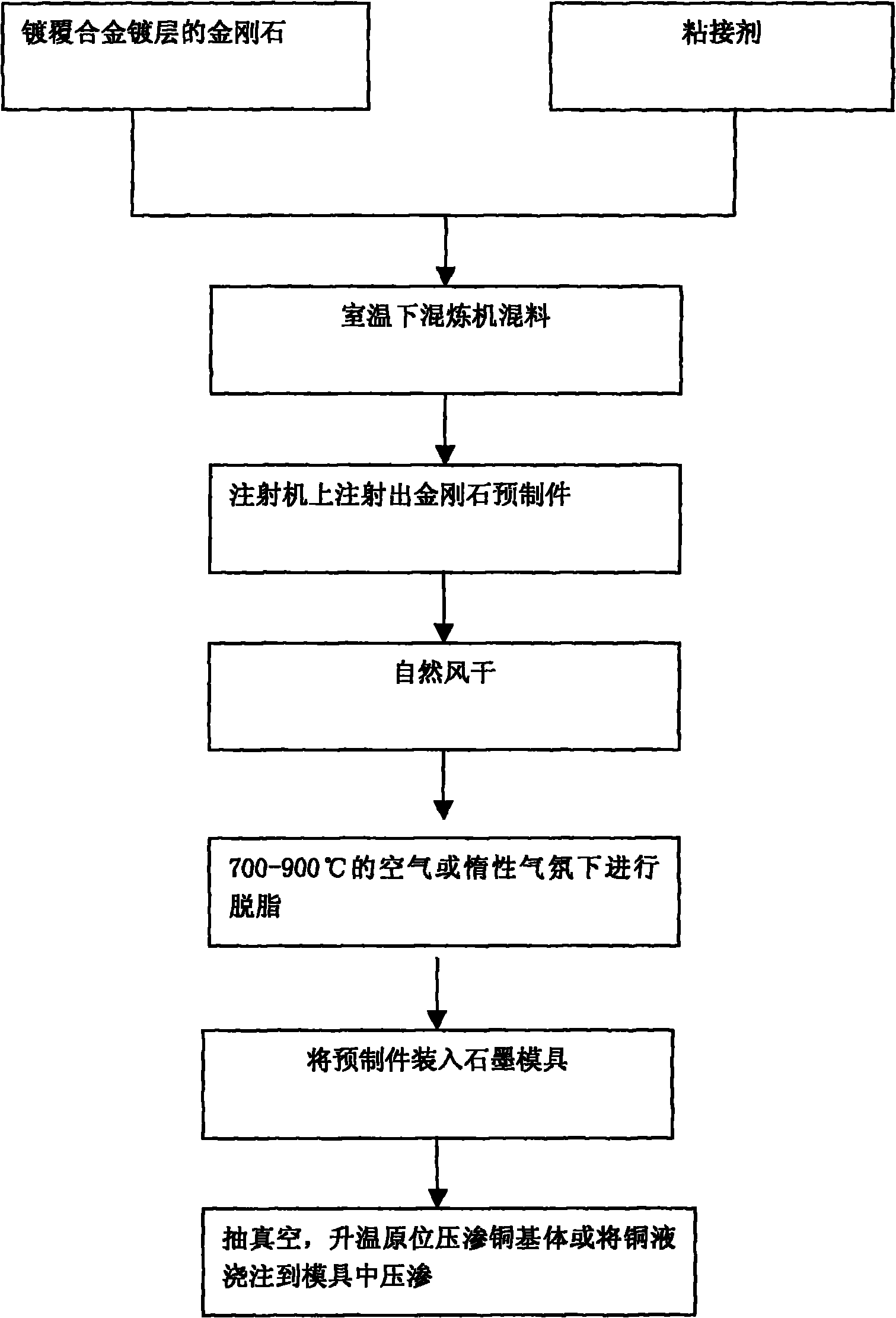

Method used

Image

Examples

Embodiment 1

[0034] Raw materials: Cu0.5Zr-plated diamond particles with a particle size of 30 μm, electrolytic copper.

[0035] Diamond magnetron sputtering Cu0.5Zr with a particle size of 30 μm, and a coating thickness of 0.2 μm, the diamond particles after plating and the binder polyvinyl alcohol in a volume ratio of 1:1 were mixed on a mixer for 1 hour at room temperature, and then The preform body is prepared on the injection molding machine. After the preform body is air-dried naturally, it is degreased under Ar atmosphere at 800°C to obtain the preform; then it is put into a graphite mold, and the electrolytic copper block is placed on the preform, and the adhesive is completely The pore volume left after removal is the volume of copper infiltration in the later stage; then put it into a vacuum pressure infiltration furnace, when the vacuum is pumped to 0.1Pa, the temperature rises to 1200°C to infiltrate the metal, the furnace is cooled, and the mold is ejected. The density of the...

Embodiment 2

[0037] Raw materials: CuW-coated diamond particles with a particle size of 28 μm, and oxygen-free copper blocks.

[0038] The diamond magnetron sputtering Cu0.5W of particle diameter 28 μ m, coating thickness 0.3 μ m, the diamond particles after plating and binder polyvinyl alcohol are mixed on the kneader at room temperature for 1 hour by volume ratio (3: 2), and then A preform body is prepared on an injection molding machine. After the prefabricated body is air-dried naturally, it is then thermally degreased and pre-sintered at 800°C under an Ar atmosphere to obtain a prefabricated part, which is then put into a graphite mold, and the oxygen-free copper block is placed in a vacuum pressure infiltration furnace cavity In the intermediate frequency induction furnace, the pore volume left after the adhesive is completely removed is the volume of copper infiltration in the later stage; when the vacuum is pumped to 0.1Pa and the temperature rises to 1200°C, the molten electrolyti...

Embodiment 3

[0040] Raw materials: CuCr-plated diamond particles with a particle size of 40 μm and 25 μm, electrolytic copper.

[0041]Diamond magnetron sputtering Cu0.4Cr with a particle size of 40 μm and 25 μm, the coating thickness is 0.2 μm, and the volume ratio of the two particle sizes of diamonds after plating is 7:3, and the volume of the binder polyvinyl alcohol The ratio was 4:1, and the three were mixed on a kneader at room temperature for 1 hour, and then a preform body was prepared on an injection molding machine. Soak the preform body in gasoline for 24 hours to extract and degrease the binder. After natural air drying, thermal degreasing and pre-sintering are carried out under Ar atmosphere at 900°C to obtain the preform, and then put it into the graphite mold. Put the electrolytic copper block on the prefabricated part, then put it into the vacuum pressure infiltration furnace, when the vacuum is pumped to 0.1Pa, the temperature rises to 1100 ℃, the infiltration metal furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com