High-toughness casting Fe-Cr-Mo-based high-damping alloy and preparation method thereof

A high damping alloy, fe-cr-mo technology, applied in the field of damping alloy materials, can solve the problems of complex ferritic stainless steel, unsatisfactory improvement of toughness and high cost of Fe-Cr-Mo based damping alloy, and achieve high purity Degree, improve metal flow properties, improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

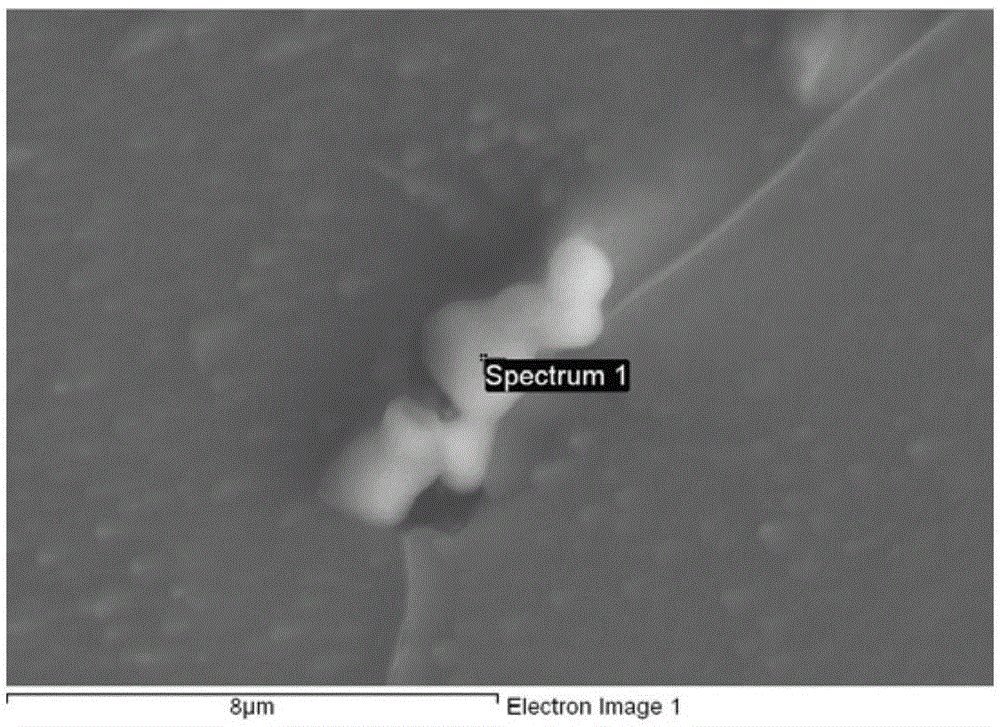

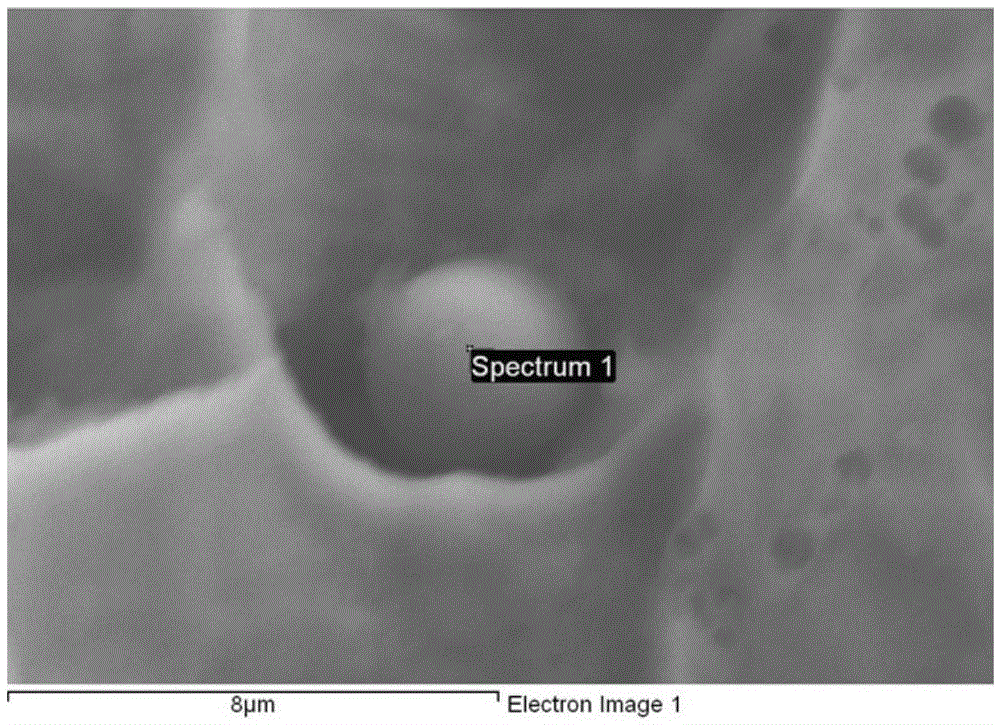

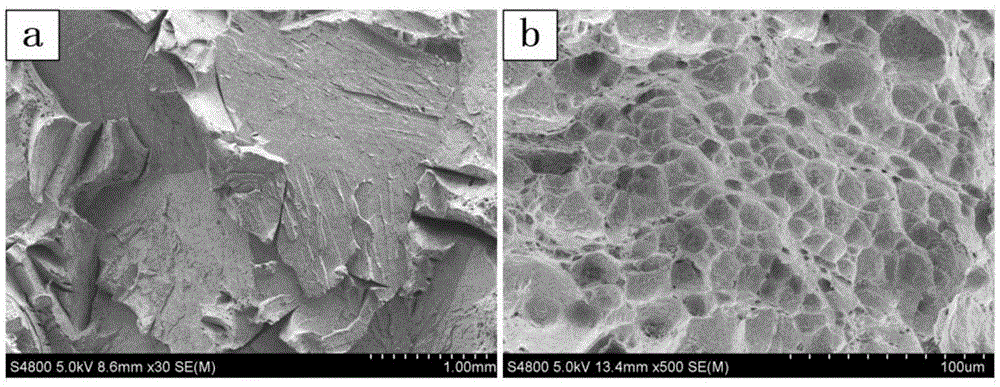

Image

Examples

Embodiment 1

[0024] The high-toughness casting Fe-Cr-Mo-based high-damping alloy described in this embodiment, the mass percentages of each component and component in the alloy are as follows: Cr is 16%, Mo is 2%, Si is 0.3%, and Mn is 1.0%, Ni is 1.6%, Zr is 0.2%, and the balance is Fe.

[0025] Preparation:

[0026] (1) Add industrial pure iron (C content ≤ 0.006%), crystalline silicon Si-1, metal chromium JCr99-A, industrial pure molybdenum Mo-1, and electrolytic nickel Ni9996 into vacuum induction melting In the crucible of the furnace, place the casting mold in the vacuum melting furnace. After the vacuum is evacuated to 0.3Pa, the electric heating is started. After all the metal is melted, it is refined at 1600-1650°C for 20 minutes. Refining is completed, stop power transmission, and stand still for 3 minutes. Then add zirconium-nickel alloy into the molten metal under high vacuum (vacuum degree not less than 0.5Pa), and fill it with argon to 0.005Mpa, then add electrolytic mangan...

Embodiment 2

[0038] The high-toughness casting Fe-Cr-Mo-based high-damping alloy described in this embodiment has the following components and the mass percentages of the components in the alloy: 15% for Cr, 2.5% for Mo, 0.5% for Si, and 0.5% for Mn 0.5%, Ni is 1.0%, Zr is 0.05%, and the balance is Fe.

[0039] The difference between the preparation method of the alloy and that of Example 1 is that the Zr source is zirconium sponge, the damping heat treatment temperature is 1050° C., and the heat treatment time is 40 minutes.

[0040] After testing, the impact toughness of the obtained alloy is A ku is 103J, the tensile strength of the alloy is 375MPa, and the elongation is 23.9%; when the alternating strain is 8×10 -5 When, the damping performance Q -1 is 0.0455.

Embodiment 3

[0042] The high-toughness casting Fe-Cr-Mo-based high-damping alloy described in this embodiment, the mass percentages of each component and component in the alloy are as follows: Cr is 17%, Mo is 1.5%, Si is 0.8%, and Mn is 0.6%, Ni is 1.2%, Zr is 0.1%, and the balance is Fe.

[0043] The difference between the preparation method of the alloy and Example 1 lies in that: the Zr source is zirconium sponge; the damping heat treatment temperature is 1000° C., and the heat treatment time is 80 minutes.

[0044] After testing, the impact toughness of the obtained alloy is A ku It is 104J, the tensile strength of the alloy is 410MPa, and the elongation is 22.3%; when the alternating strain is 8×10 -5 When, the damping performance Q -1 is 0.0494.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com