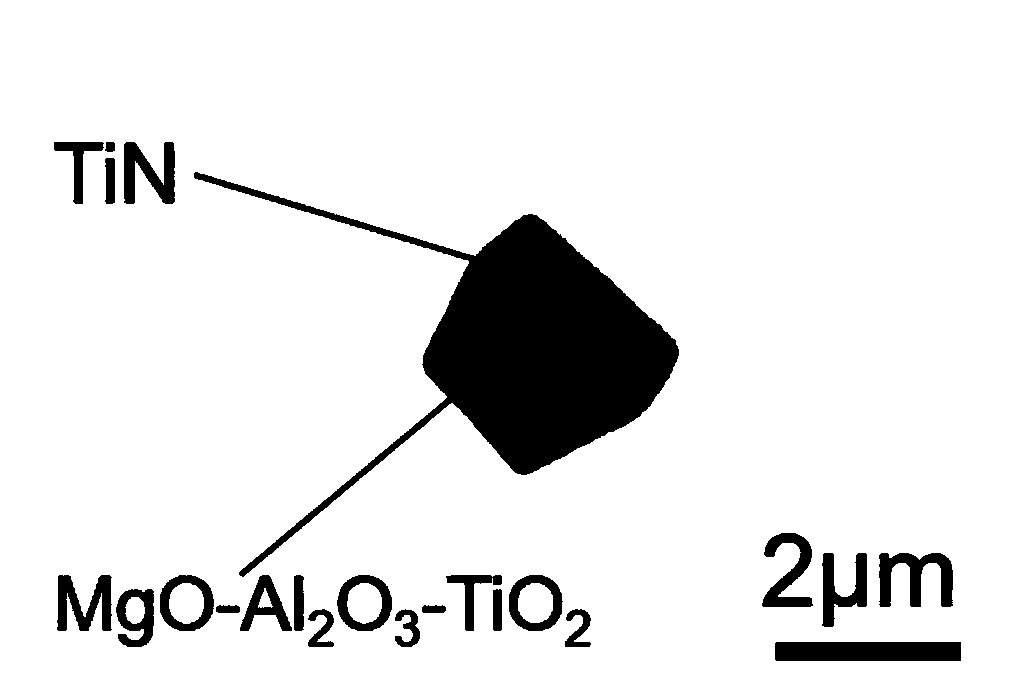

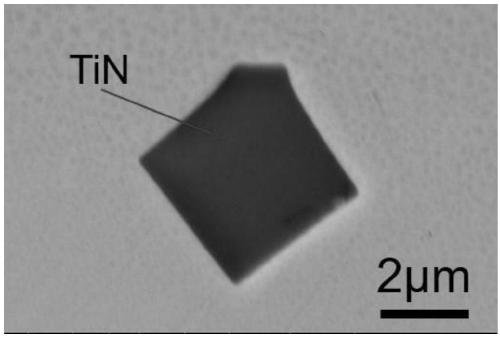

Method for refining nitride inclusions in nickel base deformation high temperature alloy

A technology for deforming superalloys and nitrides, applied in the field of nitrides inclusions, can solve the problems of fatigue failure and can not be eliminated, and achieve the effect of reducing the number, uniform distribution and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

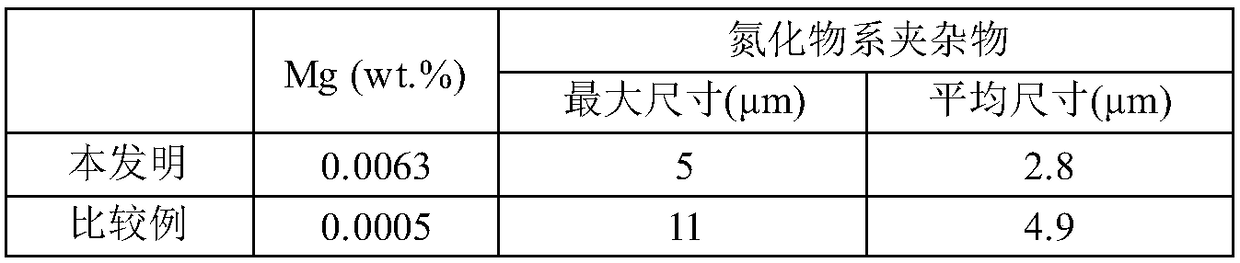

Examples

Embodiment 1

[0019] Embodiment 1: GH4169 nickel base deformation superalloy

[0020] (1) Raw material pretreatment process: using bulk pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 25 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15 minutes .

[0021] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 25 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat until the adde...

Embodiment 2

[0028] Embodiment 2: GH4169 nickel base deformation superalloy

[0029] (1) Raw material pretreatment process: using bulk pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 25 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15 minutes .

[0030] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 20 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat until the adde...

Embodiment 3

[0036] Embodiment 3: GH4220 nickel base deformation superalloy

[0037] (1) Raw material pretreatment process: using bulk pure nickel, pure chromium, pure cobalt, pure tungsten, pure molybdenum, pure niobium, pure aluminum, pure titanium, high-purity graphite, boron, zirconium, etc. as raw materials, various raw materials The purity is greater than 99.9%; metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides, and the pretreatment time is 25 minutes; then various metal raw materials are placed in absolute ethanol for ultrasonic treatment, and the treatment time is 15 minutes .

[0038] (2) Vacuum induction melting process: first put Ni, Cr, Co, W, Mo, Fe, which have low affinity with O and N, into the crucible of the vacuum induction melting furnace; vacuumize to 5×10 -2 Pa, for smelting; after the melt is melted, add C and refine for 25 minutes; add strong nitride and oxide forming elements Nb, Ti, Al, and heat until the adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com