Method for preparing industrial sodium silicate by using waste copper sulfur tailings

A technology of copper-sulfur tailings and sodium silicate, applied in silicates, alkali metal silicates, chemical instruments and methods, etc., can solve the problem of poor quality of liquid water glass products, impurities of alumina and iron in quartz concentrates Advanced problems, to achieve the effect of high utilization rate, huge economy, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

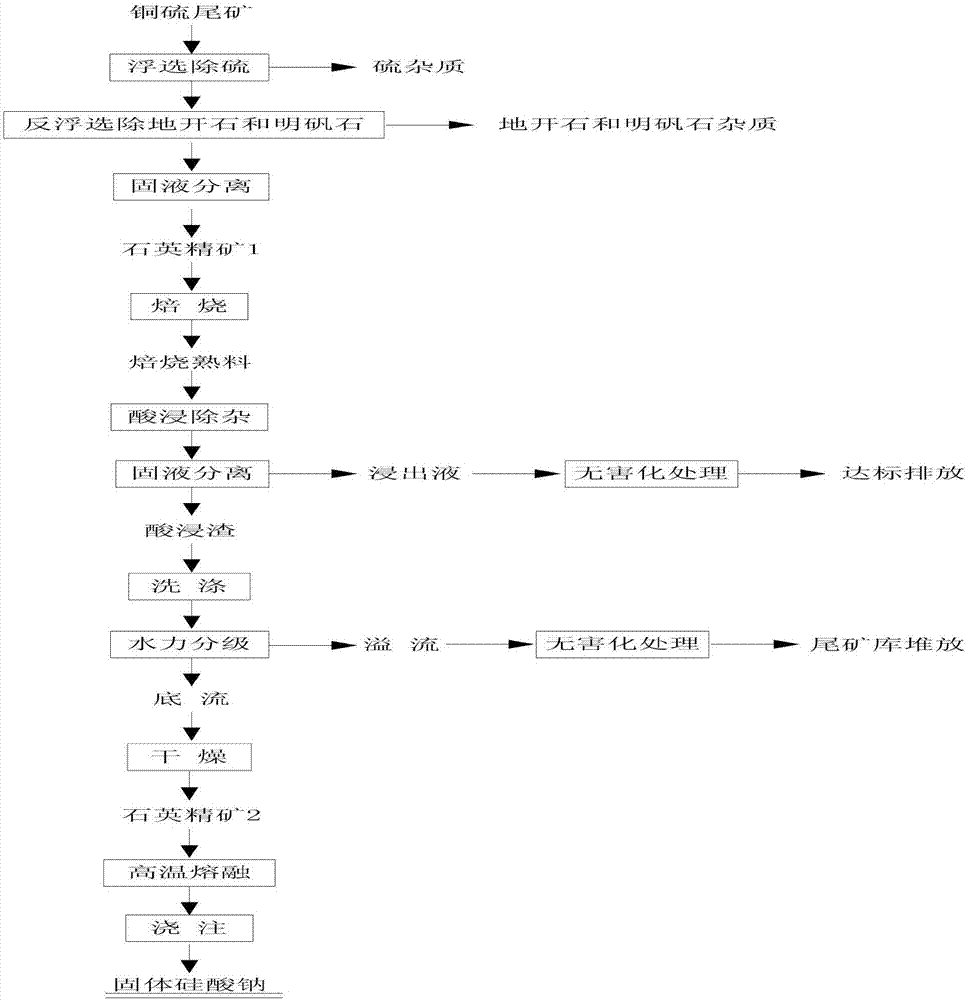

Image

Examples

Embodiment 1

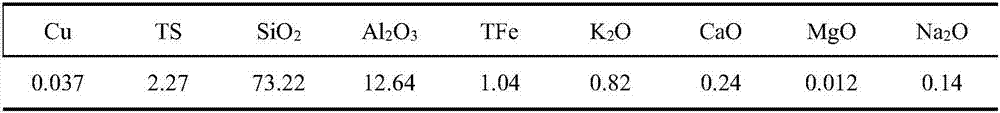

[0028] A copper-sulfur tailings mine in Fujian needs to use SiO 2 Mainly, followed by alunite and dickite, a small amount exists in the form of sericite, feldspar, chlorite, epidote, etc. The chemical multi-element analysis results of copper-sulfur tailings are shown in Table 1.

[0029] Table 1 The multi-element analysis results of a copper-sulfur tailing in Fujian (%)

[0030]

[0031] A method for preparing industrial sodium silicate from waste copper-sulfur tailings, which comprises the following steps and conditions in sequence:

[0032] The first step of flotation to remove impurities: first add sulfuric acid or sulfuric acid solution to adjust the pH value of the copper tailings slurry to 3.0, then add butylammonium black medicine at 60-80g / t and stir for a certain period of time, then add at 10-15g / t No. 2 oil is subjected to flotation to remove sulfur impurities, and tailings slurry 1 is obtained after removing sulfur impurities; tailings slurry 1 is then added wi...

Embodiment 2

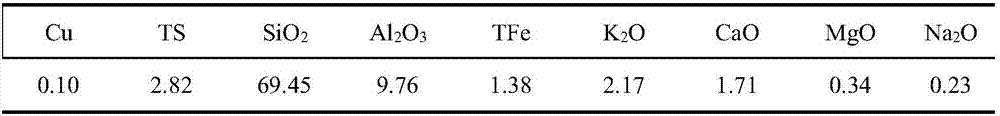

[0038] A copper-sulfur tailings mine in Jiangxi needs to use SiO 2 Mainly, followed by alunite and dickite. The chemical multi-element analysis results of the copper-sulfur tailings are shown in Table 2.

[0039] Table 2 Multi-element analysis results of a copper-sulfur tailings in Jiangxi (%)

[0040]

[0041] A method for preparing industrial sodium silicate from waste copper-sulfur tailings, which is carried out in the following steps and conditions:

[0042] The first step of flotation to remove impurities: first add sulfuric acid or sulfuric acid solution to adjust the pH value of the copper tailings slurry to 4.0, then add the collector agent butylammonium black drug and stir for a certain period of time, then add the foaming agent No. 2 oil for flotation Remove sulfur impurities, and obtain tailings slurry 1 after removing sulfur impurities; tailings slurry 1 is then added with collector dodecylamine and collector sodium oleate in sequence and stirred for a certain ...

Embodiment 3

[0048] A copper-sulfur tailing in Heilongjiang needs to use SiO 2 Mainly, followed by alunite and dickite, and a small amount in the form of detrital quartz, microcrystalline quartz and kaolin. The chemical multi-element analysis results of the copper-sulfur tailings are shown in Table 2.

[0049] Table 3 Multi-element analysis results of a copper-sulfur tailings in Heilongjiang (%)

[0050]

[0051] A method for preparing industrial sodium silicate from waste copper-sulfur tailings, which is carried out in the following steps and conditions:

[0052] The first step of flotation to remove impurities: first add sulfuric acid or sulfuric acid solution to adjust the pH value of the copper tailings slurry to 5.0, then add the collector agent butyl ammonium black drug and stir for a certain period of time, then add the foaming agent No. 2 oil for flotation Remove sulfur impurities, and obtain tailings slurry 1 after removing sulfur impurities; tailings slurry 1 is then added wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com