Manufacturing method of columnar crystal Al-Ni-Co-Ti permanent magnetic alloy

A technology of AlNiCoTi and permanent magnet alloys, which is applied in the field of manufacturing technology of columnar crystal AlNiCoTi permanent magnet alloys, can solve problems such as difficult machining, unsatisfactory magnetic properties, high brittleness and hardness of products, and reduce breakage Effects of edge drop, improvement of machinability, and improvement of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Ingredients: ingredients by weight percentage as follows: aluminum A1: 7%, nickel Ni: 15%, cobalt Co: 38%, copper Cu: 3%, titanium Ti: 5.5%, niobium Nb: 0.6%, holmium Ho: 0.5%, Tantalum Ta: 0.3%, Bismuth Bi: 0.3%, Sulfur S: 0.2%, Selenium Se: 0.2%, and the balance is iron and unavoidable trace impurities in materials; in order to reduce the melting point of metal tantalum, ensure that tantalum and When the weight percentage of niobium in the ingredients remains unchanged, it is added in the form of tantalum-niobium alloy, in which the weight percentage of tantalum is 60% and the weight percentage of niobium is 40%.

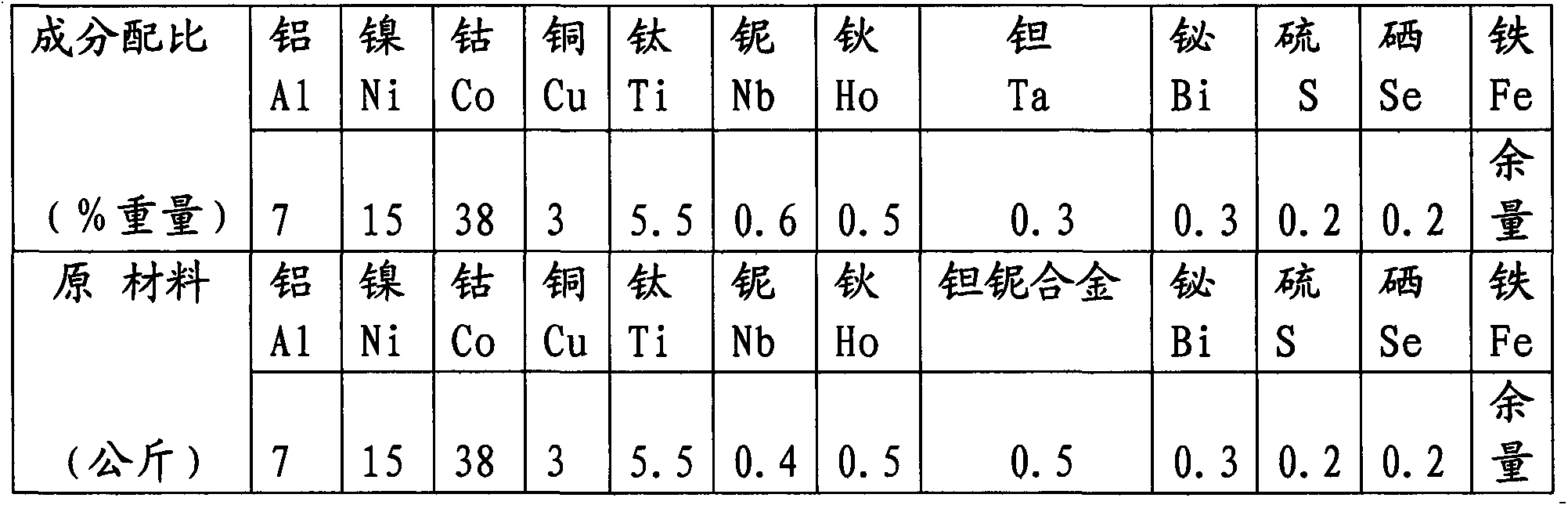

[0033] Taking the smelting of 100 kg AlNiCoTi permanent magnet alloy as an example, the distribution ratio of each component is shown in Table 1-1:

[0034] Each component distribution ratio in the embodiment one of table 1-1

[0035]

[0036] The niobium in the raw material adopts niobium powder, the tantalum-niobium alloy adopts flakes with a thicknes...

Embodiment 2

[0053] Ingredients: ingredients in the following weight percentages: aluminum Al: 7.5%, nickel Ni: 14.5%, cobalt Co: 36%, copper Cu: 3.2%, titanium Ti: 6%, niobium Nb: 1%, holmium Ho: 0.8%, Tantalum Ta: 0.6%, Bismuth Bi: 0.3%, Sulfur S: 0.4%, Selenium Se: 0.4%, and the balance is iron and unavoidable trace impurities in materials; in order to reduce the melting point of metal tantalum, ensure that tantalum and When the weight percentage of niobium in the ingredients remains unchanged, it is added in the form of tantalum-niobium alloy, in which the weight percentage of tantalum is 60% and the weight percentage of niobium is 40%.

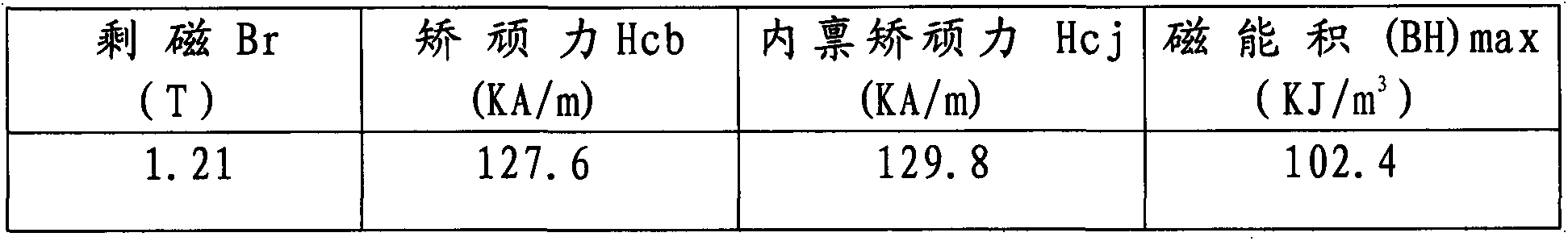

[0054] Taking the smelting of 100 kg AlNiCoTi permanent magnet alloy as an example, the distribution ratio of each component is shown in Table 2-1:

[0055] Each component distribution ratio in the embodiment two of table 2-1

[0056]

[0057] The niobium in the raw material adopts niobium powder, the tantalum-niobium alloy adopts flakes with a th...

Embodiment 3

[0073] Ingredients: ingredients in the following weight percentages: aluminum A1: 7.8%, nickel Ni: 14.5%, cobalt Co: 37.5%, copper Cu: 3.3%, titanium Ti: 6.5%, niobium Nb: 1%, holmium Ho: 1.3%, Tantalum Ta: 0.9%, Bismuth Bi: 0.5%, Sulfur S: 0.5%, Selenium Se: 0.4%, and the balance is iron and unavoidable trace impurities in materials; When the weight percentage of niobium in the ingredients remains unchanged, it is added in the form of tantalum-niobium alloy, in which the weight percentage of tantalum is 60% and the weight percentage of niobium is 40%.

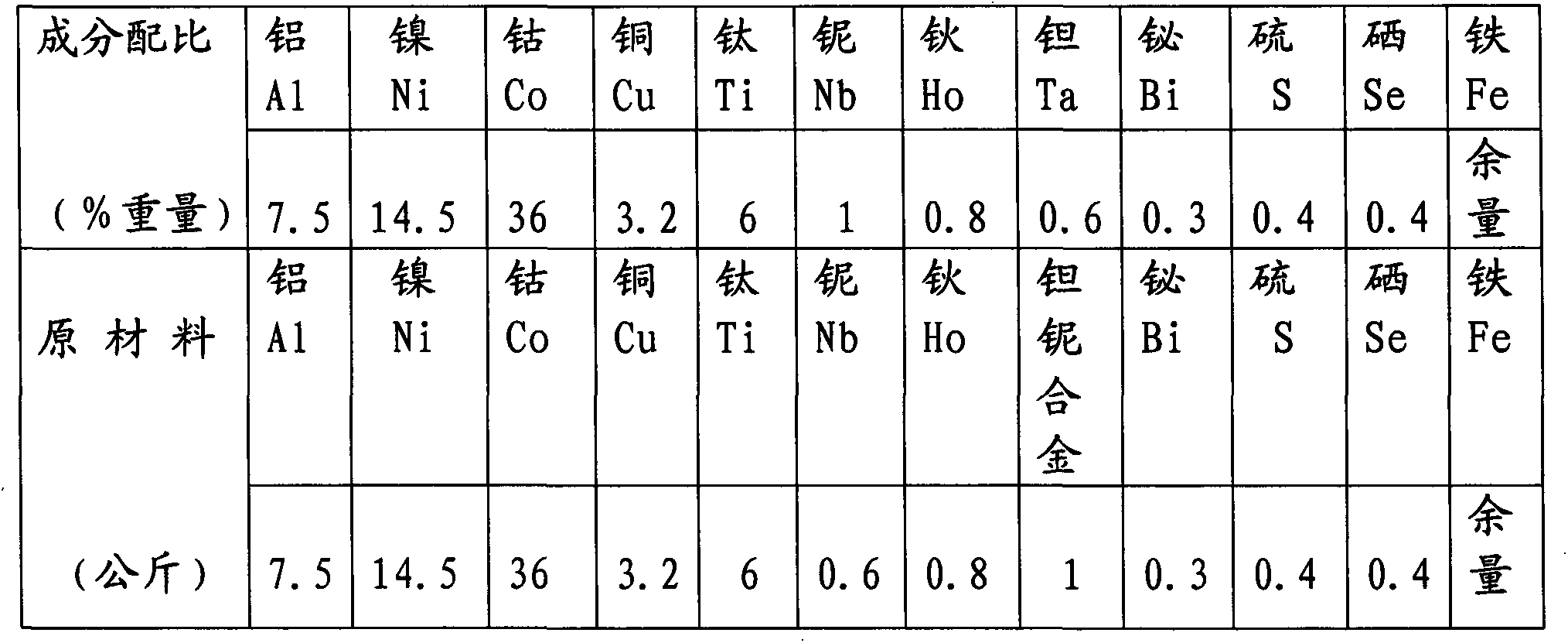

[0074] Taking the smelting of 100 kg AlNiCoTi permanent magnet alloy as an example, the distribution ratio of each component is shown in Table 3-1:

[0075] The distribution ratio of each component in the third embodiment of table 3-1

[0076]

[0077] The niobium in the raw material adopts niobium powder, the tantalum-niobium alloy adopts flakes with a thickness less than 1 mm, and other metal materials are in the form of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com