Melting dosing method in two curcibles utilized in procedure of melting and pouring nonferrous alloy

A non-ferrous alloy, quantitative feeding technology, applied in crucible furnaces, equipment for supplying molten metal, metal processing equipment, etc., can solve problems such as energy and material waste, reduce melting costs, and facilitate the control of pouring temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

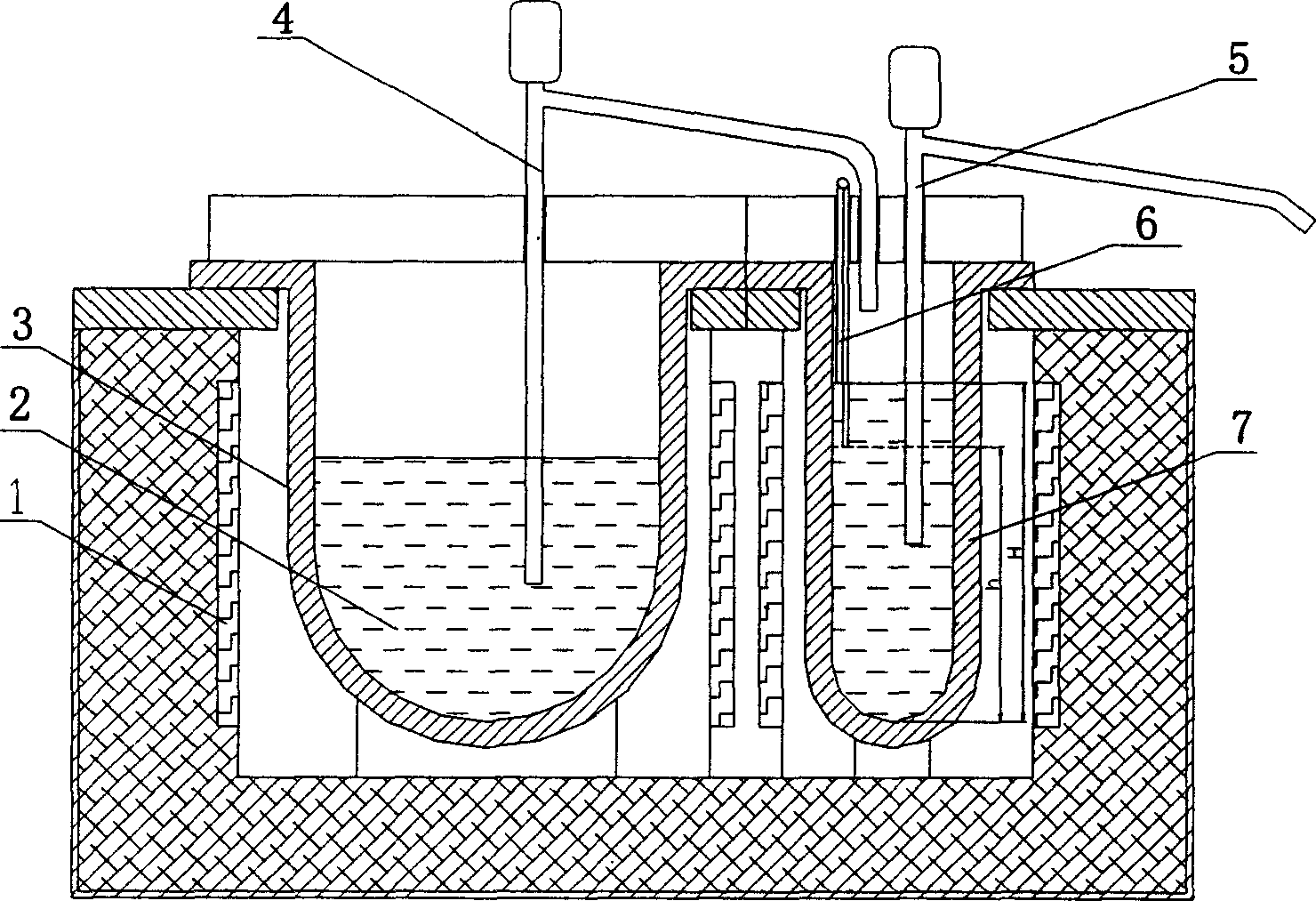

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] The melting and heat-preservation casting of alloy are respectively finished by two sets of independent crucibles, and the diameter of melting crucible 3 cross-sections is greater than the cross-section diameter of heat-preservation pouring crucible 7, (for example, the diameter of melting crucible 3 cross-sections is 7 cross-sections of heat-preservation pouring crucibles 2-5 times of the diameter) A sensor 6 for feeding back liquid level information is set in the heat-preservation pouring crucible; The pouring feed pump 5 that pours out, the specific quantitative feeding method is as follows:

[0010] The heating element 1 simultaneously heats the melting crucible 3 and the heat-preserving pouring crucible 7. During the melting and pouring process of non-ferrous alloys, when the height of the metal liquid level in the heat-preserving pouring crucible 7 is lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com