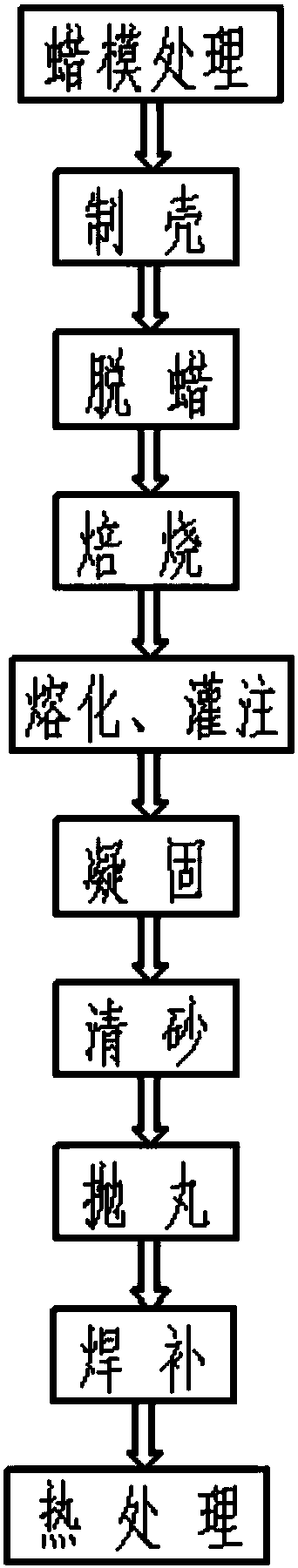

Valve precision casting environment-friendly technology process

A technological process and precision casting technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of failing to meet the environmental protection standards of the foundry industry, threatening the natural ecological environment, complex technological processes, etc., and achieving easy molding and trimming. , low melting point, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

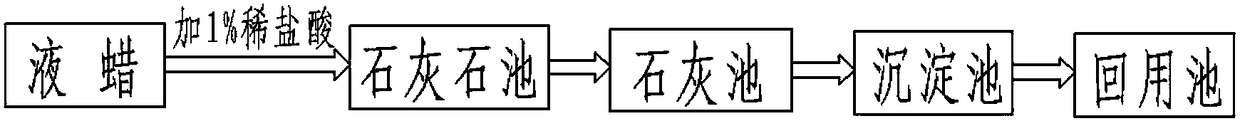

[0045] An environmental protection technological process of precision casting of valves, comprising the following steps:

[0046] A. Wax mold modeling: Heat the block wax and the wax material recovered from dewaxing to form a liquid mold material, stir the mold material evenly and settle for 2 to 5 hours, filter to remove impurities, and then filter the mold material The material is adjusted into a paste, poured into the molding equipment for cooling and molding, and the wax mold after cooling and molding is pressed and then cleaned and trimmed to remove flashes and burrs on the wax mold. Due to the low melting point of the wax material, the manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com