Gas atmosphere shielding device of smelting and pouring magnesium alloy

A protective atmosphere and magnesium alloy technology, applied in the field of equipment in the field of alloy processing, can solve the problems of high use cost, limited use conditions, single gas use, etc., and achieve the effects of low cost, precise mixing ratio, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment:

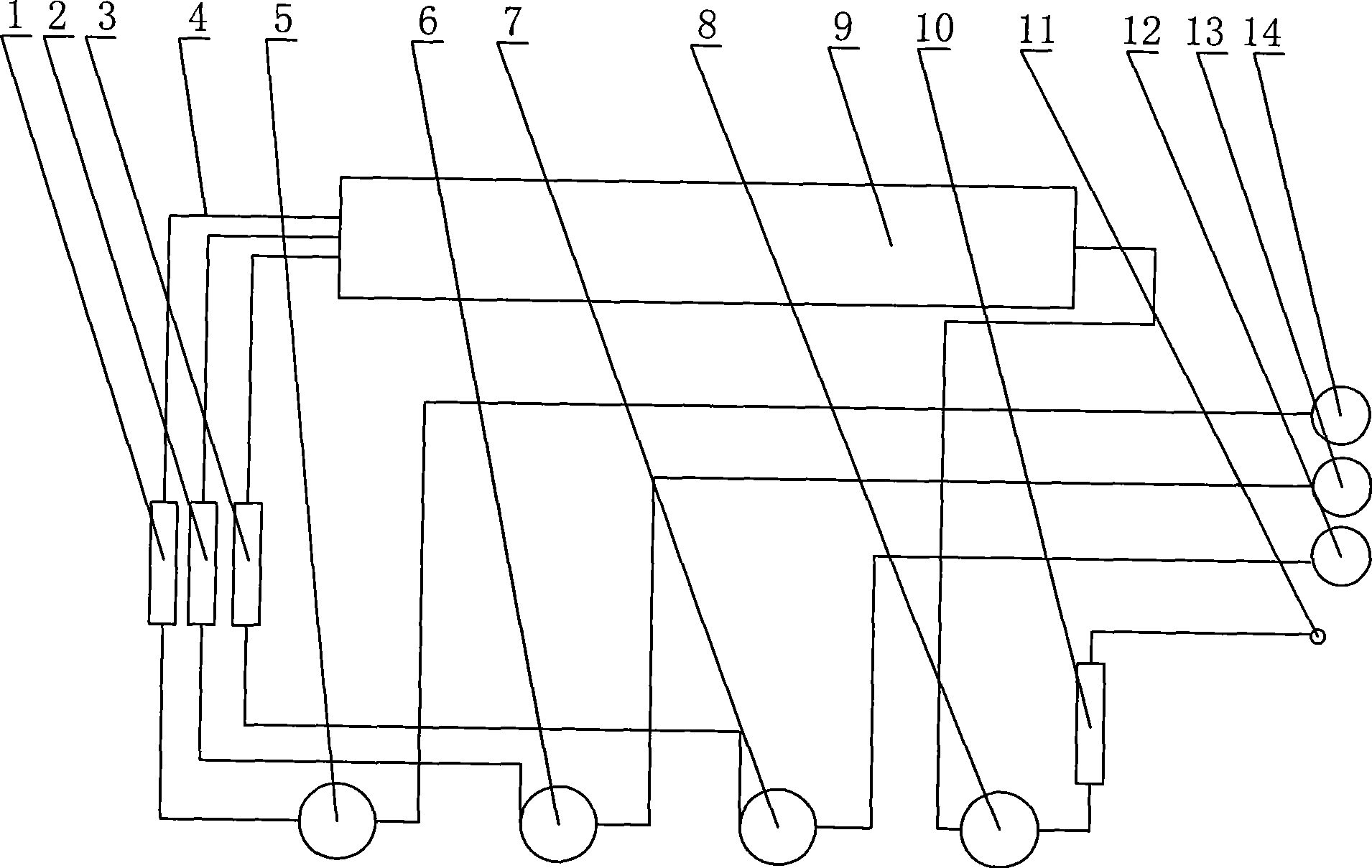

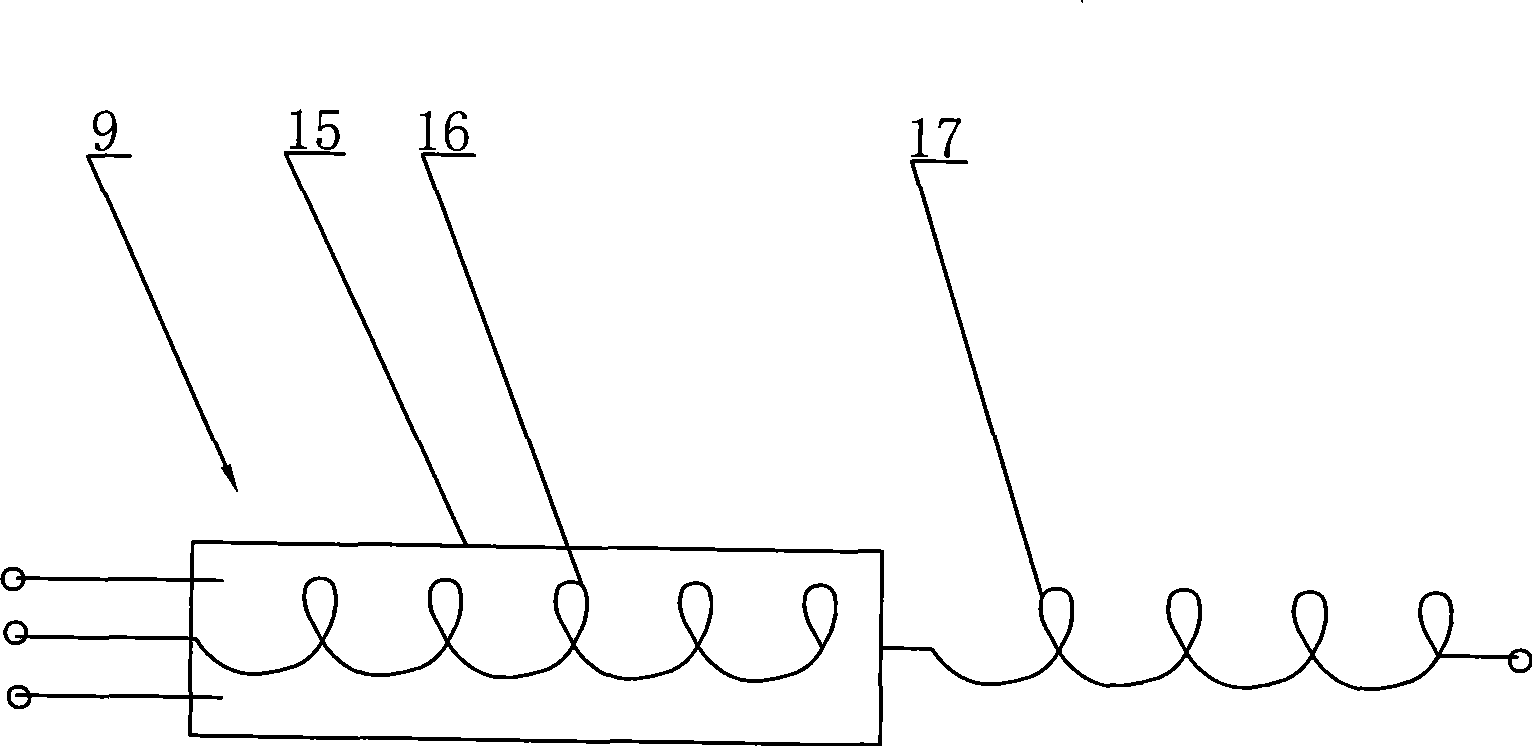

[0009] Such as figure 1 As shown, a protective atmosphere device for magnesium alloy smelting and pouring, it includes a pipeline 4, a sulfur hexafluoride gas cylinder 12 connected to a three-way air inlet, a carbon dioxide gas cylinder 13, a nitrogen gas cylinder 14, a mixer 9 and a mixing Between the gas outlet 11, the three-way air inlet and the mixer 9, there are intake pressure detection and adjustment device 5, intake pressure detection and adjustment device 6, intake pressure detection and adjustment device 7, intake flow detection and adjustment device 1, inlet Air flow detection and adjustment device 2, intake air flow detection and adjustment device 3, there is an outlet pressure detection and adjustment device 8 and an outlet flow detection and adjustment device 10 between the outlet of the mixer 9 and the mixed gas outlet 11, and two or three kinds of gases can be mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com