Method for energy-saving charging and discharging of cells and system for testing energy-saving charging and discharging of cells

A charging and discharging and battery technology, which is applied in the field of battery energy-saving charging and discharging testing, can solve the problems of large discharge current ripple coefficient, large volume of power storage devices, and large power grid harmonic pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A battery energy-saving charging and discharging method of the present invention comprises the following steps:

[0060] A. First connect each battery to the corresponding DC-DC conversion unit, each DC-DC conversion unit is connected to one end of the common DC bus, and the other end of the common DC bus is connected to one end of the DC-AC conversion unit, the The other end of the DC-AC conversion unit is connected to the grid;

[0061] B. When the battery is in the discharge state, the battery releases energy to the common DC bus through the DC-DC conversion unit;

[0062] C. When the battery is in the charging state, the battery absorbs the energy of the common DC bus through the DC-DC conversion unit;

[0063] D. When some batteries are in the charging state and some batteries are in the discharging state, the batteries in the discharging state release energy to the common DC bus through the DC-DC conversion unit, and the batteries in the charging state absorb...

Embodiment 2

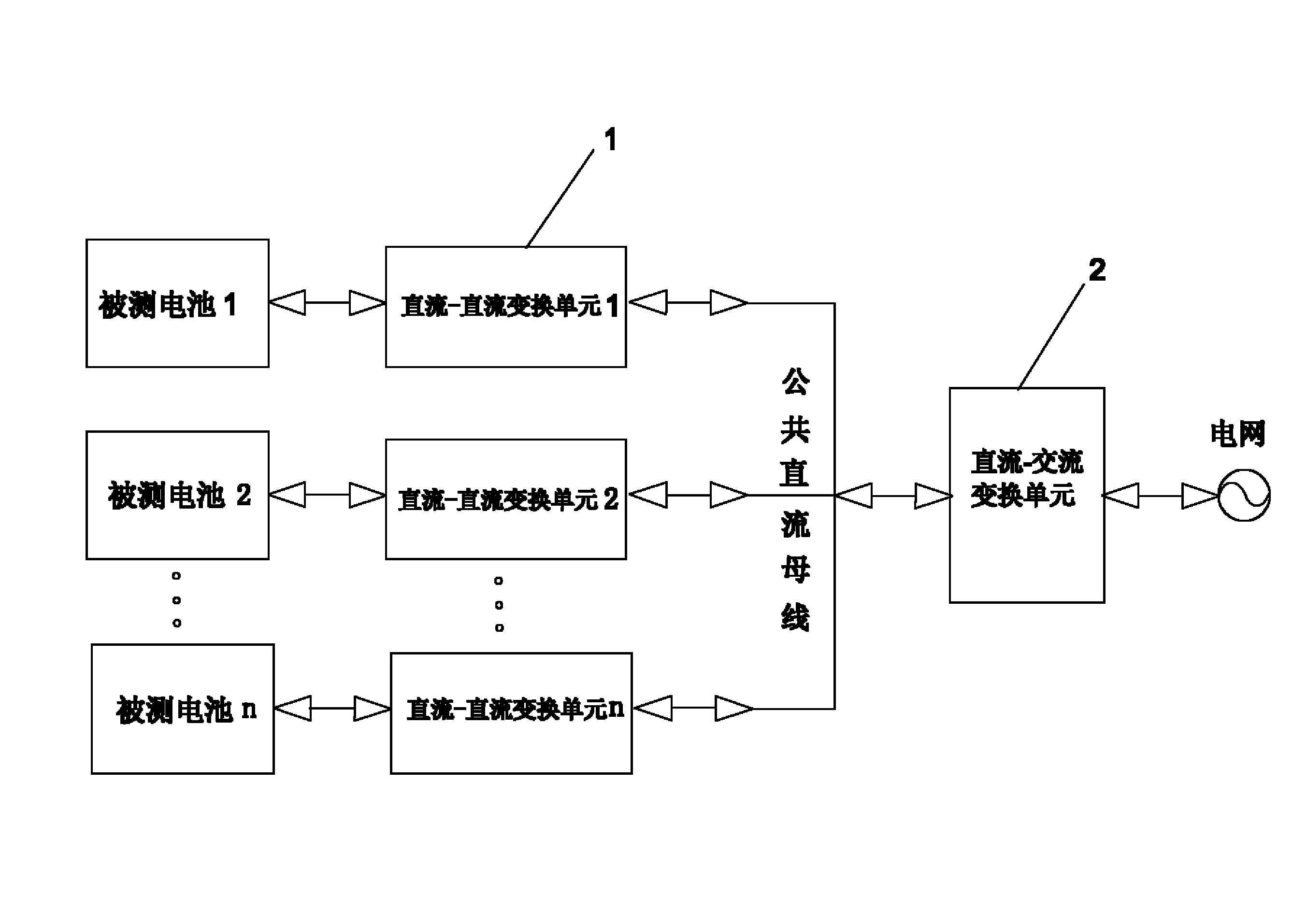

[0068] A battery energy-saving charging and discharging test system of the present invention is as follows: figure 1 As shown, it includes a battery under test, a DC-DC conversion unit and a DC-AC conversion unit 1, each battery under test is connected to a DC-DC conversion unit 1, and the DC-DC conversion unit 1 is connected to the DC-AC through a common DC bus. The conversion unit 2 is connected, and the DC-AC conversion unit 2 is connected to the power grid.

[0069] There are three working modes of the system:

[0070] 1. When all the batteries under test are in the charging state, the energy from the grid passes through the DC-AC conversion unit 2, the DC-DC conversion unit 1, and the battery under test in sequence, that is, the grid energy charges the battery under test after passing through the test system;

[0071] 2. When all the tested batteries are in the discharge state, the energy from the tested battery passes through the DC-DC conversion unit 1, the DC-AC conv...

Embodiment 3

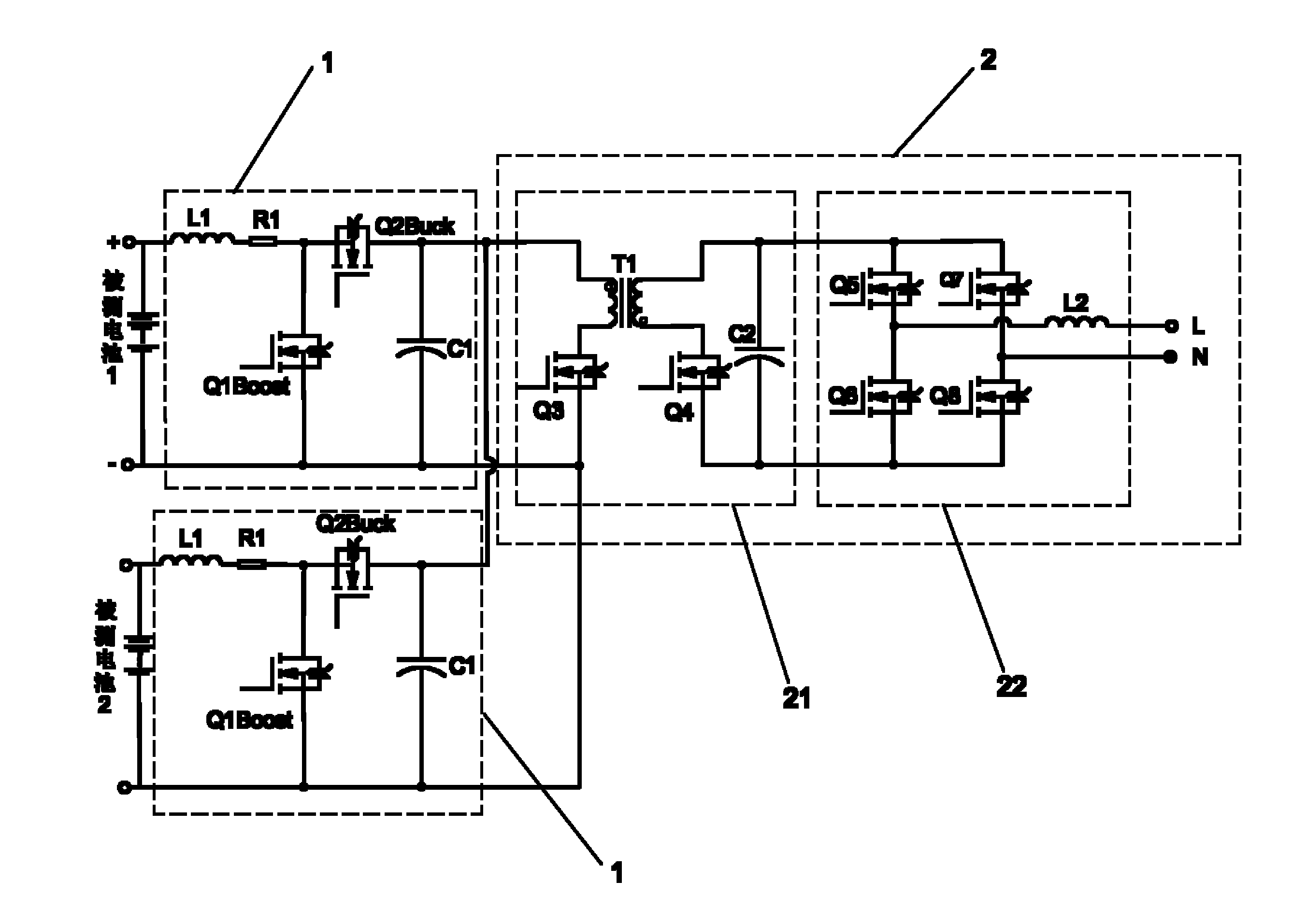

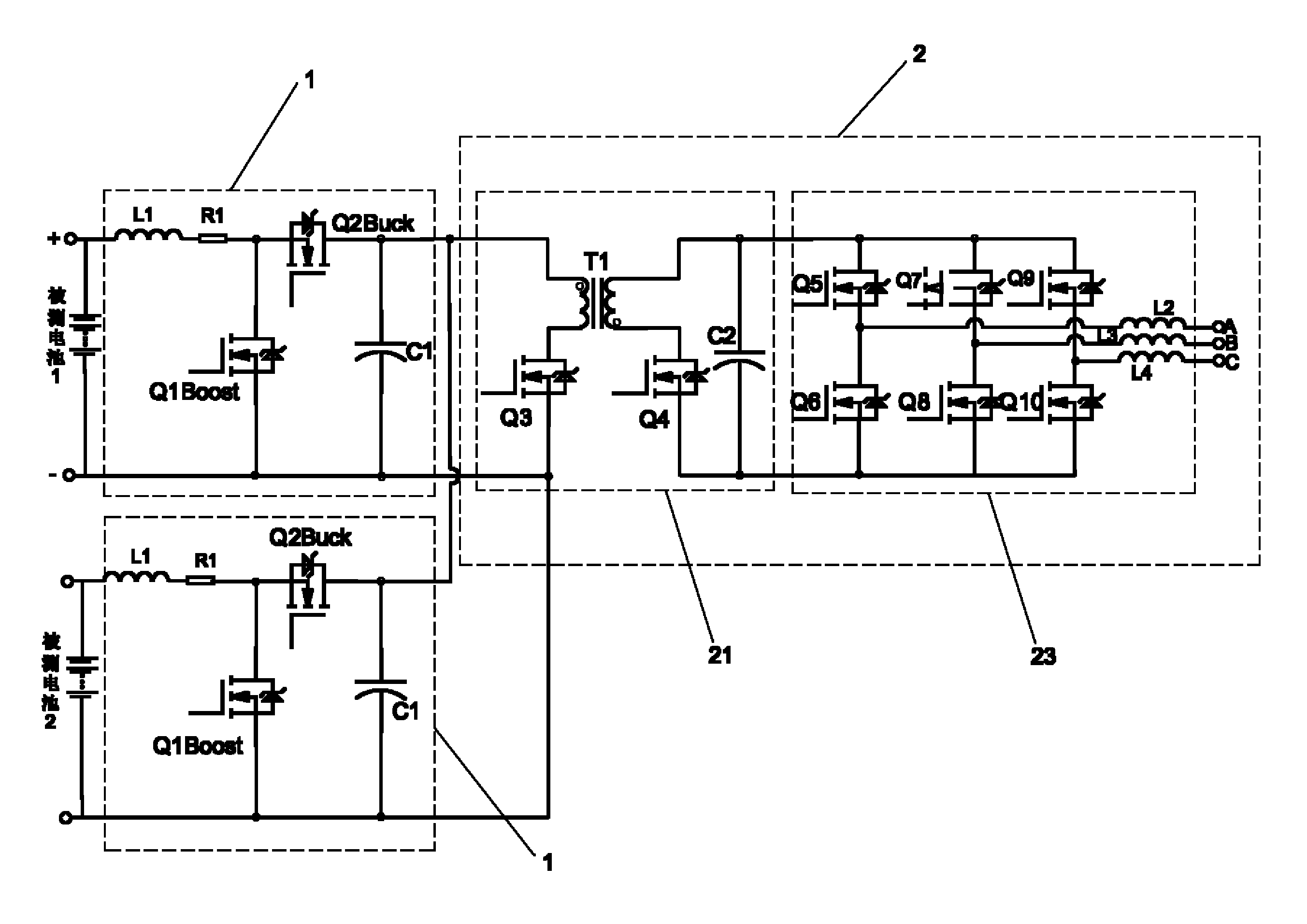

[0076] A battery energy-saving charging and discharging test system of this embodiment is as follows: figure 2 As shown, on the basis of Embodiment 2, the features not explained in this embodiment are explained in Embodiment 2, and will not be repeated here. The difference between this embodiment and embodiment 2 is:

[0077] The DC-DC conversion unit 1 is provided with a BUCK / BOOST bidirectional non-isolated DC-DC conversion circuit, and the BUCK / BOOST bidirectional non-isolated DC-DC conversion circuit includes an inductor L1, a resistor R1, a capacitor C1, and field effect transistors Q1 and Q2 , one end of the inductor L1 is connected to the positive pole of the battery under test, the other end of the inductor L1 is connected to one end of the resistor R1, and the other end of the resistor R1 is connected to the source of the field effect transistor Q2 and the drain of the field effect transistor Q1. The drain of the tube Q2 is connected to one end of the capacitor C1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com