Wiper arrangement and method for operating a wiper arrangement for a motor vehicle

A technology for automobiles and wiper arms, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as low control accuracy and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

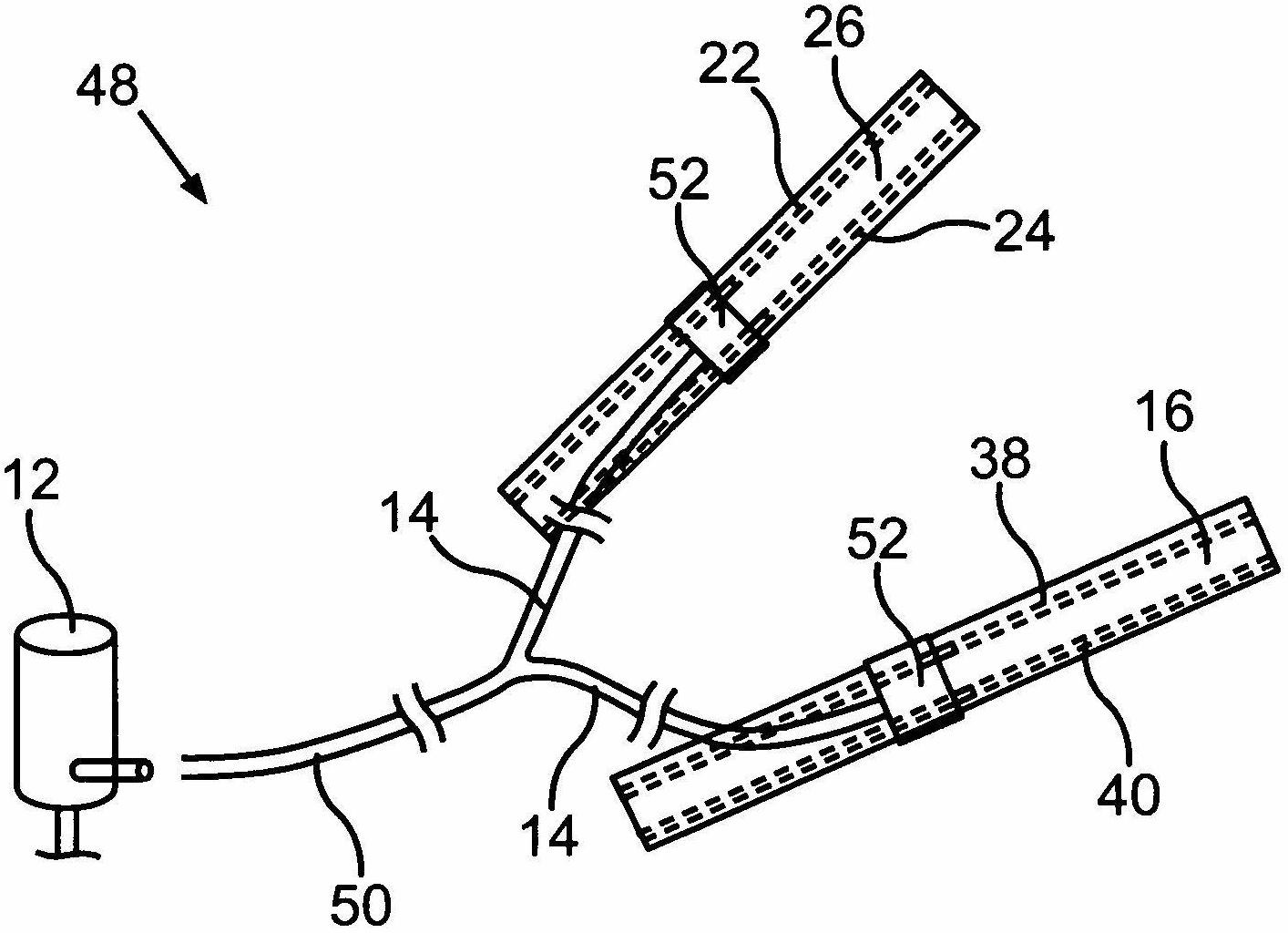

[0026] figure 1 Pump 12 of a windshield washer system in a wiper system 48 of a motor vehicle that delivers washer fluid from a (not shown) storage container is shown. Of the wiper device 48 comprising two wiper arms and wiper blades 16 , 26 fastened to the wiper arms, only the driver-side wiper blade 16 and the passenger-side wiper blade 26 are shown. The supply lines 14 leading to the respective wiper blades 16 , 26 are connected to the pump 12 via a common line section 50 . If the pump 12 builds up a certain cleaning fluid pressure in the common line section 50 , this pressure is exerted in the individual delivery lines 14 .

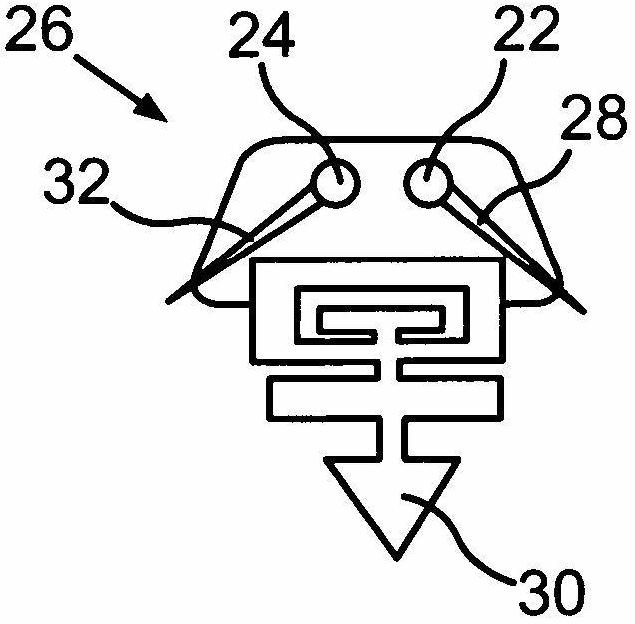

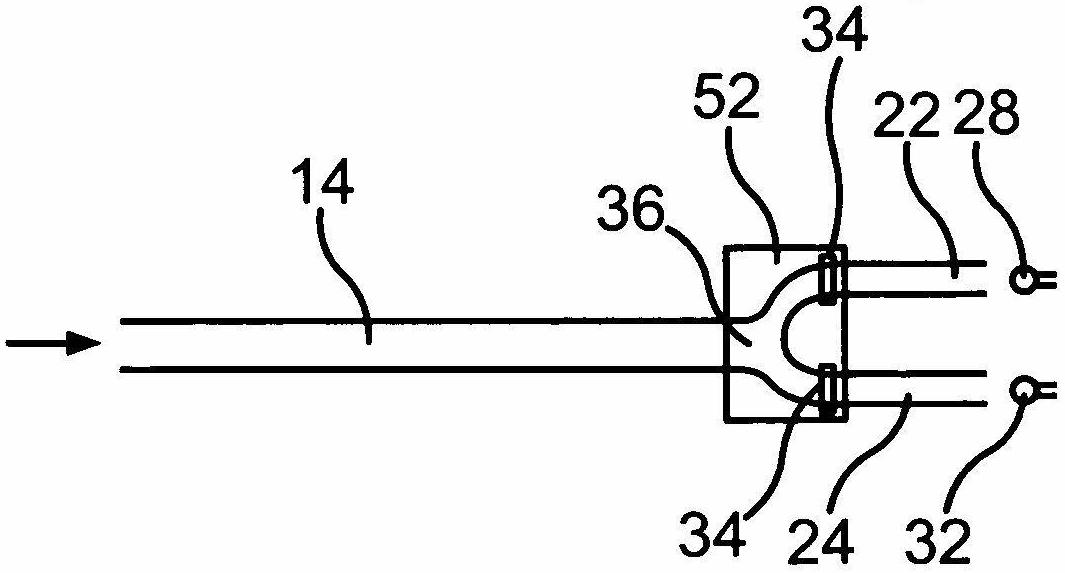

[0027] The wiper blades 16 , 26 are connected to the respective (not shown) wiper arm via respective connecting pieces 52 . Each delivery pipe 14 leads into the connecting piece 52 and there at the branch point 36 (refer to image 3 ) are connected to the respective two distribution pipes 22, 24, 38, 40. The distribution lines 22 , 24 of the wiper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com